When you buy through links on our site, we may earn an affiliate commission.

Search the Community

Showing results for tags '2836'.

-

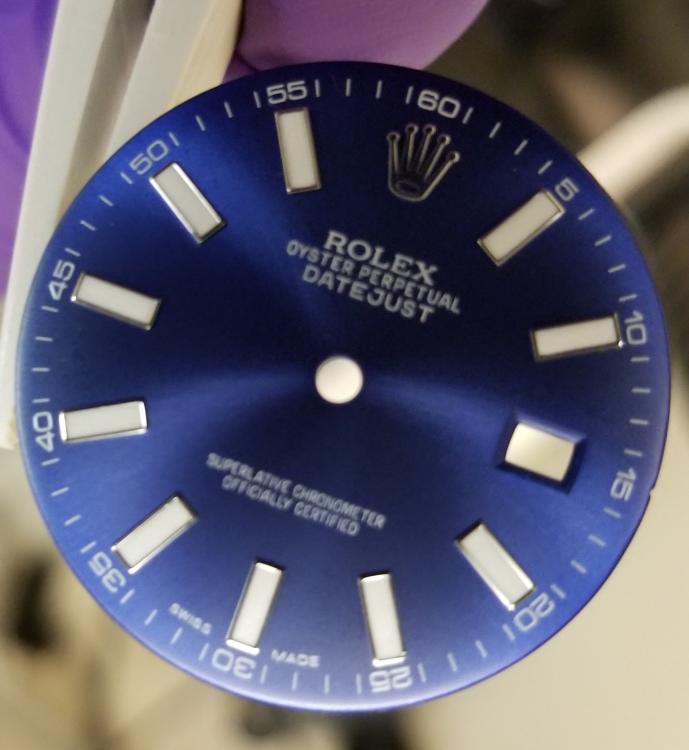

The story is the Ordered a watch that have a Lower Crown of the dial and the wrong color lume ( green instead of blue). The TD sent me the replacement dial.....with Still the wrong color lume......So I decided not to worry about it anymore Since the Rep stops working every couple days. Im am thinking of sending it off to be relumed, Dial replaced and serviced....Any recommendations ?? in US? Can you please tell me what you guys think of the replacement Dial? thicker Indices.? The old marker on the watch is crooked @ 5 mins as well. the crown on the watch dial is 3D while the crown on the new replacement dial is flat. Also the dial feet are @ min 43 and min 13, does that sound right for a 2836? Thank you folks.

-

I guess the general consensus is that you always go for the asian 2836 since the ETA- 2835 is usually old or asian anyway. so what about the Clone 3135? if the same watch is made in 2836 and rolex clone 3135 which should I go for? and is the 2836 easily swappable with a genuine 2836? or a Sellita ST2200? or a ISA ISA 2331 / 103 Quartz ?? the is the difference between clone 1:1 to bestest copy or best like gen. I have been looking at trusted dealers and cant find V2, v3...V7 or Grade A, A+, AA, AAA, superclone. How do I figure all this out. I'm looking to buy a 116300 blue DateJust 41 II with a smooth bezel. some are 199USD and others are 368USD. I cant find a difference Can someone please help me? and how come my PW doesnt work on the Android App? Thank you

- 22 replies

-

I just want to advise something based on my experience. Read ALL before you start unassemble your watch to discover you miss something necessary half way... First let me explain what reverse wheels are... They can be found only in automatic watches, and not in all of them (Seiko for instance use a cam&levers system, and also some of our 23j have the Seiko system, like the UN Maxi Marine non chrono), but definitively they are present in all ETA variants like 2824, 2836, 2834, 7750, 7751, 7752 (the gmt one) and 7753... They looks like these: They are responsible to transmit the motion of the rotor to the main spring, and work more or less like a bicycle pinion: when the rotor (your legs for the bicycle) rotates faster than the gears connected to the main spring (faster than the bicycle rear wheel), then the rotor motion is transmitted to the main spring, winding it (then your legs power is transmitted to rear bicycle wheel, increasing your speed). Instead if the gears connected to the main spring rotates faster than the rotor (typically when the watch is on the table quiet or when you manually wind the watch with the crown), the reverse wheel disengage and does NOT transmit the motion to the rotor (like on the bicycle when you are going and stop to move your legs). This is particularly valid for the single direction autowind like the 7750, but can be acceptable also for the bidirectional autowinding system like the 2836 where you have 2x reverse gears. So, what may happen to these very complicated gears? Well, basically just 2 things: 1) they can lack of lubrication, or be lubricated with wrong systems. 2) they can break. The 1st case is the most common one, and has a typical symptom: the manual winding action appear stiff, when you hand wind the watch the rotor tend to spin or really spins (typically when the watch is kept horizontally). The 2nd case (I have an Hublot with this problem) is much more rare and makes instead the autowinding system not to work at all: the rotor just rotate but doesn't charge the main spring. Only solution for this is to replace the reverse gears. Let's concentrate on the most common case. So the hand wind is stiff and you want to fix it. On 2836/2824/2834 it is not complex: you need to open the case back, then you need to remove the rotor unscrewing the big central screw here: then you need to remove the 2 screws that keeps on the autowind bridge (1.2mm screwdriver) and lift the autowind bridge. You recognize the right screws because they are normally black. They are the ones missing from the 2 smaller holes here: After you have removed the autowind bridge, put it upside down on a surface and remove the screw that keeps there the gears (reverse wheels and the other 2 reduction gears). Here you can see a VERY dirty autowind bridge upside down: You should arrive to have all in bits like in this pic where you can see 3x autowind bridge disassembled: Now it is time to properly clean all. For the 2 bridges I normally use a toothbrush with some soapy degreaser to do the first coarse wash, then I put all (gears, bridges and even the screw) in my ultrasonic cleaner loaded with a warm mixture of 50cl of ammonia + 36cl acetone + 14cc oleic acid + enough demineralized water to reach 1 liter and let them be cleaned for around 5 minutes. After this I put them into demineralized water and let them rinse in the water and in the ultrasonic washer for other 3/4 minutes. Finally you need to let everything dry over a lint-free paper (I sometime use 50°C heated oven to make the process quicker. YES YES, I know ETA lubrication charts tells to not clean the reverse wheel... They just want you to buy new ones. I did and they were stiffer than the original asian ones!!!! So now it's time to CORRECTLY lubricate those 2 bastards... There are many formulas and wizard's mixtures advertised here and there as the solution to lubricate the ETA reverse wheels (considering also the 775x movements)... I tried them all, but the only PROPER product I found to do the job is the one that ETA itself developed to lubricate their reverse wheels, and it's named "LUBETA v105" (http://hiro.alliancehorlogere.com/en/Under_the_Loupe/Lubeta_V105). It is not that cheap and I found few places that sells small amount of them. My source is this: http://www.ebay.com/itm/400720621082 Do not mess up with the V106 which is for something else (http://hiro.alliancehorlogere.com/en/Under_the_Loupe/Lubeta_V106) and that can be substituted safely with a tiny amount of HP1300. Wet well the reverse gears with this V105 product (sometimes I even immerse the reverse gears in the solution) and then let the reverse gears to dry completely over a surface (better a clean metallic one: don't use something that can absorb it or that could be melted by the V105 thinner). Then follow this chart to reassembly everything, and you will find out that the hand wind will be smooth like a brand new gen ETA (regardless it's an asian or eta movement): One last tip: when you are mounting back the rotor, do NOT tight fully the central screw: as soon as it start to get tight, make the rotor to rotate: sometimes it doesn't engage properly with the wheels of the autowind bridge, and if you tighten it in that state you can bend the wheels and make a mess... Finally: 775x is similar, but it is MUCH more difficult to unassemble and reassemble because there are a lot of bits to align to fit the autowind bridge, so I don't suggest anyone to try if it is not really confident to work on watch movements...). See here on the other RWG -> http://www.rwg.bz/board/index.php?showtopic=1039 Ah, very last thing: while on the 2836/2824/2834 you can fit gen ETA spare parts, with 775x you can't (tried today with the mentioned Hublot): it seems that it fits, but the reverse gear pinions are 0.2mm for the asian ad 0.38mm for the ETA/Valjoux and even if you can then reassemble everything apparently well, then the rotor doesn't engage the reverse wheel properly... Cheers, GenTLe

-

I received a GMT Master II Asian Clone ETA 2836 from Marvellous Replica a couple of months ago and am very pleased with it. It ran about 15 seconds fast at first, but I bought the Kello app and was able to regulate it so it's about +5 sec/day. The bracelet was not very smooth at first, but I soaked it in WD40 and that made a noticeable improvement. The bezel has a little slack to it, but it's not bad--only about 1/2 minute counter clockwise. Also, the lack of AR on the cyclops makes the date a little hard for me to read sometimes. The flaw on this particular watch is the lume on the minute hand. The factory put a blue hand instead of a green one. My plan is to have the entire watch re-lumed some day. Luckily, out of site, out of mind so I don't notice it most of the time. A lume shot was not one of my requests during the QC process--but this is my first rep and I've learned--and am still learning!

-

Sometimes (like when you re-set the keyless works), removing the ETA 2836/2824 datewheel (DW) is a necessary evil. The easiest way to do this is to depress the double jumper spring, and shift the DW slightly crown-side (to free it from the minute train bridge, which covers the keyless works) while lifting it off. The problem of course, is that most rep datewheels are overlayed. And the overlay hides the double jumper spring from view. Needlessly removing a datewheel overlay is a PITA, because getting it straightened out again is time consuming. The other accepted method to free the DW is to unscrew the date jumper maintaining plate and/or minute train bridge by just enough. Too much unscrewing, and a little bad luck can sometimes push a part or two out of place--a real headache. What to do? Funny you should ask: I happen to have an A2836 sitting on my workbench... One solution is to remove the DW blind. You can do this by inserting a very thin object under the DW in the direction of the double jumper spring. Then you just lift everything off like normal. Yes, I'm cheating because I'm looking. But this is the best way to demonstrate the technique. Our target: between the 5 and the 6. I used a blue oiler. In this picture, the double jumper spring is pushing against the gap between the teeth of the DW (see dates 7 and 8 ) : Pull the crown into the quick-set position. Turn it so the teeth just appear between the grooves in the date jumper maintaining plate: In the picture above, look at the teeth near 7, 9, and 10. If you could somehow lift the DW vertically, those teeth would pass easily through the spaces in the plate. The problems with doing this are that (1) the spring is above the tooth near 8. Also, the teeth on the other side of the DW are beneath the minute train bridge. Forcing things here is inadvisable. You need to push that spring in. Spring is depressed: Lifting up while pushing slightly crown-side: Done: Now, this is tougher when the DWO is actually on. Probably the most difficult part is determining when the DW teeth are in the right grooves for lifting. If you pull up prematurely, the DW isn't going anywhere. Turn the crown until the date almost clicks over-- you can tell by the increasing resistance as you turn the crown. You get the hang of it, eventually. Give it a shot!

- 3 replies

-

- Date wheel

- overlay

- (and 4 more)

-

OK. You got into the movement and did what you had to do. Because you removed your ETA date wheel without disturbing its overlay, it's going to be hard to put it back. Why? The overlay covers the double jumper spring. You can't see it when the overlay is on, and you need to depress the spring. The traditional way of getting the date wheel (DW) back on is to either (1) remove the overlay, fit the DW, and then realign the overlay, or (2) [partially] unscrew the double jumper maintaining plate and/or the minute train bridge. Say you don't want to do those. It is possible to get the DW back on by reversing the steps in this tutorial, but it's a little uncomfortable because you don't have the benefit of being able to see what you're doing. Here's how to do it... (Please forgive the fact the two-hands-constraint means I have to substitute words for the missing photos). Pull the crown into quick-set position. ***What you need (a fine tipped object like an oiler, a movement, a date wheel, an overlay, and something to hold the DW/DWO--like plastic tweezers)*** The date wheel, plus one ratty old overlay Double jumper spring, depressed (It's a good idea to turn the oiler vertical here) With the plastic tweezers, set the overlayed DW down on the movement, offset a bit to the crown-side. Slide the DW over so its teeth are under the raised edge of the minute train bridge. Notice that the overlay hides the double jumper spring from view. Here, the DW is resting at an angle, tilted up at 9 o'clock, as its teeth on that side do not fit through the grooves in the double jumper maintaining plate. Now, gently nudge the DW with your plastic tweezers on the crown-side. Turn it clockwise very slowly with your tweezers. At the same time, depress the double jumper spring with your fine-tipped edge. When things line up right, the DW will just drop into place. You may have to check a few times that you're pushing in the right place with your oiler. And turning the DW by nudging it is a little unnatural at first. When things seem like they're in the right spot, remove you oiler. Press down (gently) on the DW with your plastic tweezers near the double jumper plate. If nothing pops out, advance the date with the crown. You'll know right away if things worked Eureka! Total time: about 5 minutes. Plus, no messy DWO realignment to worry about. Warning: it may take several goes--my first attempt tonight failed, but I got it on the second try. Good luck!

-

- overlay

- date wheel

- (and 4 more)

-

Quick question for you knowledgeable chaps. Dial feet on a Yuki snowflake dial. Detailed as fitting a 2472 movement. Are the feet positions on 2472 and 2836 movements the same? Second question. Stem thread compatibility between movements and crowns. For example, a 21j movement, but fitting gen crown, will it fit on the same stem? And again, 2836 movement stem, fitting a gen crown, will it fit? Thanks again folks. Bones.