When you buy through links on our site, we may earn an affiliate commission.

Leaderboard

Popular Content

Showing content with the highest reputation on 02/07/2019 in all areas

-

2 points

-

1 point

-

1 point

-

"My assumption was that 3035/3055/3075 were based on the 3000. If that’s the case, are we even sure a ref 162xx case can house your movement?" The 3035/55/75 came first (around 1977) and were high grade chronometer movements from day one. The cal 3000 is a cheapo rendition of a 3035 with a flat hairspring and no date but when they were used in the explorer they ran them through the COSC test. Imho they were trying to move up$cale (28.8k/sapphire) by going downscale (stripped down cheapo movement). For anyone who has not read the 14270 Explorer Exposure: http://www.timezone.com/2002/09/16/the-rolex-explorer-ref-14270-part-1/ http://www.timezone.com/2002/09/16/the-rolex-explorer-ref-14270-part-2/1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

1 point

-

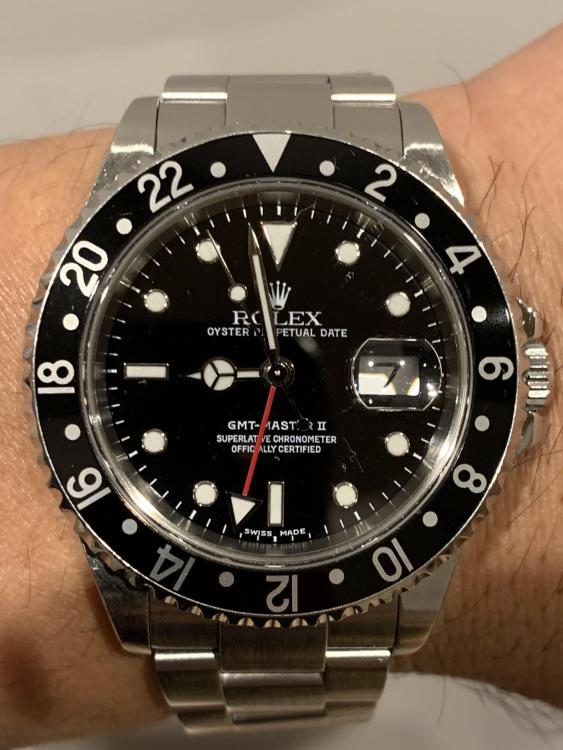

Lastly, as I said I hate debating and wished I had this picture a lot earlier to spare all the subsequent words. A picture tells 1000 words or perhaps even more!!!! This is a 904L stainless steel case with a 3135 movement Upon removing the case back seal, it is evident that these holes were not made by termites, but surely is a form of corrosion. I will let the viewers decide as to what it is, but I guarantee that it is not fly Sh*t either!!!!! It may not have been caused by H2SO4 nor HCL or even S2O3(2−) but even less aggressive oxidants in the environment which prove that 904L is nothing special. I think most of us here expect it to be as inert and noble like Gold or Platinum. . If that were the case the metallurgist who designed it would be richer than Rockefeller. Rolex could have used a titanium case instead of this 904L gag1 point

-

Most A. Lange & Sonne watches give me 1200 vickers of hardness.1 point

-

Forgot to include the online corrosion table from outokumpu who are amongst the world leading specialist in stainless steel. Here you will find a list of various chemicals tested against different grades of stainless steel and how they rank in terms of corrosion http://steelfinder.outokumpu.com/corrosion/ 904lL was specifically designed for the pulp industry and for transporting sulphuric acid. Anything with halides such as chlorides, bromides etc will be a threat to stainless depending on concentration. Iodine in ink and iodine tincture for example will be good contenders for attacking 904L. For example thiosulfate solution with high chloride ions will cause pitting of 904L. Human blood will tend to pit 316L but not 904L, so for this it would be better in case you cut yourself and blood will creep via case back under the seal. Always wash your 904L submariner with clean water straight after coming out of a spa bath, which uses bromide (halide again) salts and you will minimise risk of pitting. For the same price of a 904L rolex you could buy an 18k solid gold star supply submariner case and have an even better corrosion resistant "Rolex submariner". This is where a Franken sub would be better in terms of corrosion and scrap metal than one 904L coming out from Rolex headquarters in Geneva1 point

-

Well I do not intend to create a debate here as I prefer to listen rather than talk! I learn a lot from everyone here! I have the Avesta Sheffield reference handbook and the outukumpu handbook which we used at the University of Adelaide in the materials science and metallurgy department that although you are correct to state that the ISO standard designates a particular grade of stainless steel, it is also statistical and subject to the probability of different environments and other oxidants present. just reference this online link http://www.atlassteels.com.au/documents/Atlas Grade datasheet 904L rev May 2008.pdf and refer to page 2, for % composition of 904L stainless steel which you will see that there is a minimum and maximum of different variations of other elements/metals present . There are many factors that determine how and where it corrodes including other issues like CPT (critical pitting temperature) which really has nothing to do with the temperature but purely laboratory measures. You will find that 6Mo would have been a better choice. 904lL has copper and is high in molybdenum Try hydrochloric acid and let it seep rough the case back and let me know? Sorry to disappoint you, but I owned a 2002 Datejust with a 3135 movement that had very dark holes in the gasket groove of the mid case that looked like as if termites has eaten into it. This was the worst pitting I have seen on any watch. I am currently trying to find a photo which I had in photobucket to post, as soon as I find it, I will post it here. To epitomise all this, yes 904l is subject to corrosion given the right conditions1 point

-

hmm im sorry but 904L is a an ISO standard and the variation in quality is nearly non existent. it is the composition that makes this a 904 alloy. it is highly resistant to corrosion hence why it was made. I use it in highly acidic environments in oil production. it was designed to be used with very strong acids. The 904 on reps has been tested and does fall into the specs of being called a 904L alloy, but people seem to think that it is a super alloy and it doesn't scratch etc.. its not its actually nearly identical to 316L but has different corrosion properties. People get all bent saying "its brighter" etc and that's horseshit. its not. the whiteness or brightness in the metal has to do with how it is brushed and catches light. my recent noob Daytona is 316 and it looks exactly the same as all of my gen Rolexes. Id like to know where you got your information on 904L because its very incorrect. if what they are usisng is actually 904L then like I said it will have the same scratch and dent resistance as 316 but it will be highly corrosion resistant to acids from your skin and just about anything you will throw at it.. 904L on a watch is mearly a marketing thing as 316L is perfect for watch material and like will outlast you. The reason rolex changed was to solve the pitting issues they had in the caseback around the seal area you seen in a lot of old subs that were worn in salt water and not rinsed off, over time this will pit 316L but a very long time. most of Rolexes reason was because it was exotic, hard to work with and no one else was using it.1 point

-

I have always been very interested in AP's having gotten my first AP Royal Oak almost 20 years ago. Yes, I am embarassed to admit it was quartz. Before finding the rep forums I bought, enjoyed and sold a couple along the way. It wasn't a very efficient way though as I tended to lose money on each trade. Then I came upon the forums in the early 2000's and the first decent AP rep came - the MBW Jumbo. Of course the ETA movement was not very convincing under the clear case back but the overall dimensions, exterior finish and dial was really very good. Below is a poor pic but the only one I have and you can see it sitting next to my first gen which by the way I still own. After the Jumbo, MBW then started making seconds at 9 Offshores. The dimensions and aesthetics were great but of course it had the wrong sub-dial functionality. And for those who were obsessed with detail (i.e. correct functionality) the franken was born. The MBW and First Generation Franken era: What is interesting is that unlike most watches the first innovative franken did not come from the hobbyists or watchsmiths. It was actually built by MBW themselves in 2008 using their seconds at 9 model. At the time they made a total of 6. They got their hands on a batch of cheap dials and donor watches for the movements. And at the time they sold for either 2500 or 3500 Euro's - a princely sum. Now when they came out we all thought that they did a limited run of special cases, used gen dials and tachy rings, hands, etc. With 20/20 hindsight the beauty of using that watch was that it had dimensions much closer to gen since you were able to use a thinner standard 7750 model. The construction was nowhere near gen in terms of design but aesthetically it was closer to gen than the current seconds at 12 models. Here is an original offering pic: Here are pics of the original case when I got it. The construction may have been wrong but the dimensions were so much better than our current seconds at 12: On my end my first opportunity to try my hand at a franken came when one of the original MBW buyers screwed up his movement and sold off the watch in parts. I bought them. And what we found was that there was no limited run of cases - it was their standard case plugged and redrilled. Then we saw the hands were the rep ones with the hand tubes crudely closed to jam them on the much smaller 2892 pinions. Today we regard the larger hand tubes as one of the critical tells (the hole in a 7750 hand tube is bigger than the entire hand tube on a 2892). We also found out that the tachy ring was rep as the gen wouldn't possibly fit in the MBW bezel. So with a minimum of parts (gen dial (no tachy ring) and LWO 283 movement) a Franken could be recreated by a watchsmith with the proper skills. And thus the franken era began. On my end my first one was a rebuild of the original MBW with a new working movement and here it is: And now we knew that all you needed was the MBW watch, an LWO 283 movement and dial which matched up with the MBW tachy ring - and most importantly a skilled watchsmith. As a result an entire build was almost reasonable - unlike today. Here is one of my early "seconds at 9" builds: Back then I and one or two others built and sold a few to close friends based on whatever dials came up. And then came the seconds at 12 we all know today. Of course they had the correct functionality but the tradeoff was the thicker amended 7750 adding extra gears, etc. which required reproportioning the whole watch with thicker caseback, mid-case and bezel. As many know it does a great job of making a great rep but in larger proportion . One could say that the size difference is de-minimus as the whole watch jumped only 4mm from 13mm on the gen and MBW to 17mm on the new one. But proportionately we are talking about a 30% increase in height. I do have to say that it is a marvel though with the same functionality as gen and incredibly close gen construction later. The Second Generation of Seconds at 12 AP Frankens With the coming of the Seconds at 12 (and it's close to gen construction) now there was a theoretically better base for frankens where the gen tachy ring could be added.but the bar had to be lifted. The whole case needed a diet and a better movement ring had to be made. And as time has progressed over the last couple of years.improvements have included improved custom movement rings, lowering of the height and reconfiguring of the inside of the bezel (to fit the gen tachy ring) and of course the slimming of the caseback and even mid-case. Hobbyists and watchsmiths like Francisco, Sander, Loosetime and Ziggy all continually raised the bar further. I am sure some of these names ring a bell. Today these frankens can take virtually all gens parts - dials, tachy ring, hands, crown, pushers, crystals and even gaskets. And at least one watchsmith can service the base movement and even the chrono-module. By the way even AP simply replaces the chrono module. We of course don't have that luxury. Here are a couple pics of the last two frankens I own but there are plenty of other pics of the limited number of frankens on the forum. The Future Unfortunately it is probably dimmer. AP gen parts are now virtually impossible or prohibitively expensive to purchase so Frankens as we know it may very well never have the same level of "frankeness" but at the same time different folks are now making carbon parts and even cases and folks are even pursuing gen dial projects. So we shall see. I hope folks have enjoyed my diatribe.1 point

-

1 point

-

B- I have 7.25-.50" wrist. The strap and buckle are huge relative to the normal offshore set-up. On the length my strap is regular length (but it is gen) and it is set on the second to tightest hole. ROO's do actually wear larger than most PAM's due to the extended lug/strap section, the extended cg's housing the pushers and the height resulting from what is a module chrono movement on the gen. It does look big but in reality it actually sits fairly nicely on my wrist with the lugs wrapping around the wrist. Here is another one on the same wrist with a standard AP bands strap.1 point