When you buy through links on our site, we may earn an affiliate commission.

-

Posts

360 -

Joined

-

Last visited

Everything posted by Tiyal

-

Time to throw the chains on.

-

Where's the bezel coming off at? The clip or is the crystal retainer coming off. If it the crystal retainer, Try to drop a Clark tropic 39 or a 19 in it. Maybe you'll get lucky. The last cartel 1665 I bought had / has the assembly with the crap plastic gasket between the crystal and retainer. I was able to press on a 1680 bezel (Clark) but the fit is tight. I haven't messed with it since it's just hanging in the parts box. Sounds like you have a little extra space so may the gen spec crystal will fit and keep the retainer on. If it's just the bezel clip you could swap that out with a better one. WSO or I'm sure people have a ton in the parts box. I'd send you one from the cartel, if you'd like. Won't be home for a week though. PM. The Clark 1680 did fit.. Barely. Crystal breakage is an issue. Order a couple. Theres this from WSO http://pages.ebay.com/link/?nav=item.view&alt=web&id=160907267371&globalID=EBAY-US they also have a 1665. I bet it's exactly the same. I'd order both. Just to see. Good luck

-

Next day, not to bad. Cleaning inside the lug holes helped bring out the luster. Little big at 1.3mm but the spring bar has the right look on the wrist. I think a case polish at some point soften up the lugs a little.

-

All opened up and buffed out. Not happy with the lug holes. They need some sweet loving camfer and its just not there. I refuse to even photograph them. Lol

-

On a layover in Hiroshima, After opening up my lug holes on my 5513 I never got to debur perfectly. This has been on the todo list for a couple months. It's very very slight but you know how theat goes. I've been in Hiroshima for the past couple days. Today I was in a department store called Tokyu Hands. They had a little watch repair section. Case openers, dust blowers, loupes etc. Also all the metric drill bits I could ever want. Great tweezers stainless steel buffing cloth and micro fine sanding mesh. Time to kick back and re-drill some lugs. Then eat ramen and drink beer.

-

This is great!!!. Let's keep this alive https://www.shapeways.com/product/L6HSDJ38E/dwotool-v1-1mm?li=shortUrl&key=0ab43a09bbf7959ecd88dbc54b19c55a Just ordered this. Looks legit. $16 total

-

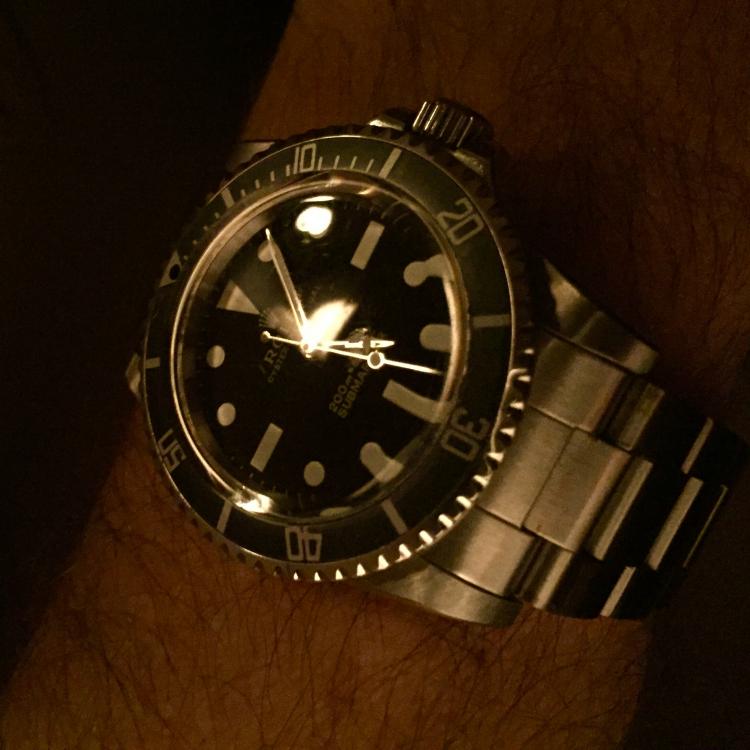

What are you wearing on your wrist for Easter Sunday?

Tiyal replied to naturopath's topic in General Discussion

-

-

Ohhhhhhhhh! Nice!

-

http://youtu.be/qtgAJBPPefM at minute 13:15 it's all keyless works. To be clear, I'm not saying decase and head into the keyless works. The video is more for reference and a visual of what's going on behind the scenes. Just take the case back off. You've obviously figured out how to remove the stem by pressing down on the back side (button) of the return bar** chime in if its the setting lever. Sometimes I press (gently) on that button that releases the stem. But instead of sliding -out- the stem see if you can push it in a little further. Might take a little gentle effort. Key here is to get the stem correctly in place. It might need that push. I use a 1mm screwdriver on the button. Anything smaller and you could possibly drive it all the way through totally jacking up the keyless works (Gentle). Then with pressure on the button use good tweezers to assist in sliding the stem toward / into the movement. (Gentle). You've got it when it stays in and clicks three times. (Video) Good luck

-

This. Does the stem come right out? Can you set the hour and date? Congrats on first build. Looks great. Sounds about right, totally nonfunctional. I destroyed mine. It gets easier. With more practice. Guys will chime in and get it sorted out. Hopefully it's simple. was the stem part of yukis kit? (Pre attached to the crown?)

-

-

Early sixties pointed crown guards, gilt 1675 GMT-Master, pic heavy

Tiyal replied to Nightwatch's topic in The Rolex Area

Love it! Great write up. Almost ready to pull the trigger. All the pieces are there. Just having a little issue with the case. It would seem I tapped it at a bit of an angle. The crown sits just off center and touches the lug. Some day I'll commit.- 21 replies

-

5513 Crystal retaining ring; Pls help/need advice

Tiyal replied to Nightwatch's topic in The Rolex Area

Looks bad ass! -

-

-

This. (plus everything else) Give up on the old hands, reorder a set or two from Star Time watch supply (tudor), Clark on eBay is really fast, TC, Yuki, where ever. I like the hour hand from star time the best. Keep trying. I think that second hand is toast. Good luck

-

On the wrist the distortion is minor. Looks great. The CWP I'm sure is great, but I'm stoked and that's what counts.

-

This is an awesome read! Brings tears to my eyes. I want more of the blowtorch story.

-

Your set up on the left (both) looks great. I try and fail not like gold hands on vintage sub.

-

For the Clark it was clarity and refraction at the edges. Instantly stunning. I like the metal bracelet, that adds to the luster. But the crystal was the biggest change. Went from like to love. That said, I'm already trying to talk my self out of swaping out the dail and hands. At that point I'd drop a pearl in. ... And quick insert bleach. Never ends lol

-

All, Seriously it's an amazing watch & thanks to Rolexfinder for getting this batch of MBWs on the board and on our wrists. They are great. I'm by no means a pro at modding and you'll see that through my write up here. But I do a have a few hacks(*) that can help some of you out there for your own build. Got in on the January batch of MBWs picked up a 5513, I like the subtleness of the no date. Watch arrives and it's beautiful. I wore it on canvas for a few weeks until I could spend a few hours hammering out the details and get a few parts in. I ordered up a Clark T19, WSO 580 end links and a clasp from TC. About $75 in total. 1. Lug holes. Mask the case, you will end up scratching no matter how careful you are. 2. I used the standard 1.2mm. In retrospect I would go for 1.25 or 1.3mm to let the pin show just slightly better but I had a set or 1.2 bits to burn up so there you go. *3. This is great. No power drill! No drill press! Slide the bit into an exacto handle and tighten down. I lubed the bit with some lithium gasket grease and went slow. I was able to get three out of for opened up to 1.2 until I got impatient. Worked great! When I started to rush and use less grease I snapped the bit and broke it off in the lug. I've never not broken at least one bit off. Not a real big deal you just go through the other side and eventually it will get pushed out by the opposing bit. Patience is key. Go slow. If you hear scraping add lube so you don't over torque and snap the bit. 4. De-cased the movement and loosened the crystal retainer. Applied hand pressure and the crystal comes right off. 5. Test fit the T19 with both the retainer and case worked great. Found a gasket for underneath the the retainer. Applied a layer of glue (jewelers adhesive) to the outside lower case neck. Then cleaned and cleaned and recleaned to make sure no glue would get near the top or onto the rehaught and crystal. Slipped the t19 on checked again (last chance) for wayward glue. (I would of used crystal cement but I broke the applicator) *6. Time to grease the gasket up (a little extra helps it stay in place as the retainer get positioned. I don't have a crystal press, for that matter any press. In the past I've used a 22mm socket (horrible idea) I found that a sodastream bottle worked perfect as it seats right against the retainer! And with the right amount of pressure the retainer was set. 7. Bracelet. I had an NOS rep bracelet sitting in the parts drawer that I had already opened up to 2mm. Off with the clasp, on with the TC. A little thread lock on the screws and stunning. Note the TC clasp finish is superior, to the band but on the wrist you'll never know. 8. Fk up the keyless works. My favorite thing to do of all time. I sued a .6mm screw driver (bad) to release the stem and drove it through the opening pushing the setting lever up into the operating lever rendering the whole works INOP. 9. De-case again, hands off, dial off. 10. Watched this video 6 times http://youtu.be/qtgAJBPPefM at minute 13:15 it's all keyless works. At minute 15:15 they op engages the setting lever spring on the setting lever and the return bar. *That's key, I think I've missed that in the past and thought that I'd killed the movement. So, reset all that, dail on, hands on and positioned. 11. Time to clean up. Clean the dial off with rodico. Blow the interior of the crystal off wipe down repeat, repeat again. Clean the case threads with rodico. Recase, check in direct light, decase clean again, curse the dust, repeat. 12. Gaskets greased, steam goes in with a little help. Not easy but I got it. (Would of gone gen crown here but it'd need a new gen tube) 13. Final assembly, grease the case gasket, torque the case back tight, bezel and insert on (popped the pearl out almost immediately, I like the look). 14. Clean with semichrome then windex then a little stainless cleaner. Light buff on the case where I didn't follow my own advice and mask. 15. Enjoy. The new crystal makes a huge!!! Difference in the watch.

-

Liking mine. When I get home, add 580s & do the TC clasp thing and a Clark and leave it. Maybe the insert. By the way, not waterproof at all. Not even slightly, mine picked up moisture from the nato. So check your gaskets.

-