-

Posts

8 -

Joined

-

Last visited

Posts posted by Thevintagecrown

-

-

On 1/4/2020 at 8:06 AM, beanvatan said:

Very nice! OP, what is the total cost for the build? If you dont mind sharing. I have build 16233 with the roman irovy dial and it cost me almost a gen price! Considering most of the materials are gen, ie gen bezel, crown, crystal, hands, dial, crown tube. Reshape JMB case, MMM 18k gold over lay vintage bracelet. 16200 raffle caseback, VR3135 serviced, Rolex replacement Date-Wheel. Gen 3135-130 (winding bridge), gen 3135-140( complete auto wind). Total cost is more than $2000, I do not remember the specific number, but, it is very darn close to a gen price! Lol.

Sent from my iPhone using Tapatalk16233 Nice! That would be the next build I think

the total cost is around $325 so it’s a cheapie

nice beater I think

nice beater I think

i will upgrade it with a gen 2836-2 in the future

Just now, Thevintagecrown said:16233 Nice! That would be the next build I think

the total cost is around $325 so it’s a cheapie

nice beater I think

nice beater I think

i will upgrade it with a gen 2836-2 in the future

-

1

1

-

-

On 12/30/2019 at 9:59 PM, alligoat said:

With a rafflesdial case it comes with the crown and tube so I see no point in installing another rep crown and tube. It also comes with a case back- I don't know if a gen case back will even fit, but what's the point?

With a gen dial, first you have to cut the dial feet off flush.

Next you can remove the day wheel and install the DWO- that's the tricky part- getting it aligned correctly.

Glue the dial to the movement ring and then install the hands.

Install the crown to the movement stem- you'll need to get the stem to right length- not too long or too short

The rafflesdials case should come with a spacer ring. Remove the stem and crown and install the movement/dial with the spacer ring. With some movement tabs and screws you screw down the movement inside the case so it doesn't move around.

Install the stem and crown. Make sure there's not dust in the case and put the case back on.

Assuming it all checks out, you can install the bracelet and enjoy you new watch.

Hey thanks for your advice

The crown is not gen spec and caseback also 😁

On 12/31/2019 at 1:12 AM, automatico said:"Install the crown to the movement stem- you'll need to get the stem to right length- not too long or too short."

Good advice.

I have to 'fess up.

I admit to cutting quite a few stems too short over the years...but there is a quickie fix if it is not cut too short. If the stem is 1mm or so too short, you can stuff some solid core solder chips (not acid core) in the crown tube where the stem screws in to add length to the assembly. I would not call this a 'botch job' but more like an emergency fix...many pro repair guys do this trick but since it does not show, most will not say anything about it. You can cut slivers of solder off the roll with a razor blade.

You can remove the solder with a small drill bit in a pin vise if needed later on but some usually stays in the threads and can cause the stem to get in a bind...but there is a fix for that too: Cut a tiny notch longways in the end of a spare stem and run it in and out a few times to clean the solder out of the threads like a thread tap does.

The 'short stem' fix will always depend on the crown tube having enough threads to begin with, about one and a half or two turns is probably the minimum after the fix.

'Crown tube' = the little threaded tube sticking out of the crown, not to be confused with the case tube.

If the stem is too long it can bind the crown when screwed down and could damage the main plate or slide the movement\dial over to one side. On glued on dials it can break the dial away from the calendar spacer etc if there is enough room for the movement to slide over. If there is enough room between the movement/movement spacer and case, the movement could slide over far enough to jam the hour wheel hub against the dial hole and stop the watch. All kinds of little mishaps can occur and many are hard to spot.

Something else...be sure there is enough room between the case tube threads and the crown when unscrewed to allow the crown to 'declutch' when it is pushed in to start the threads. Otherwise the crown will be winding the watch when screwing the crown down making it hard to start, hard to turn, plus putting spring pressure on the stem pilot when it turns. The pilot is small and is not designed to turn under pressure. This can also wear the seating surface on the main plate. This is also why you should not push the crown in toward the case when manually winding watches.

Pilot = the sharp point on the stem.

I know all this is boring but it is better to know about it now than when something goes wrong and you have to start looking for the cause.

Hey

I have replaced some stems

I first mounted the crown on the stem then I put it in the movement then I measured the distance from the end of the tube to the crown all the way in that distance I then cut the stem and always went well

i hope this is the correct way

-

Mooie build!

-

Hey guys

I started with a 16200 build. I ordered the following components- raffles 2836-2 case

- gen 16200 silver dial

- arf crown and tube

- gen caseback

- tudor 2824-2 hands

- Asian 2836-2 because of the movement height

- raffles braclet

- raffles 3135 dwothis is my first official build

i have worked on cartel watches before but never datejust. Are there people with the same build? if so give me some advice i have all the tools and will upload photos when everything is in

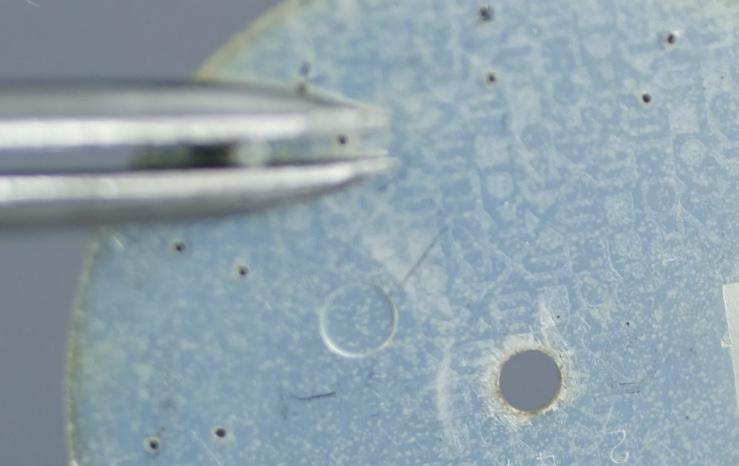

here Some pictures of the dial

Franken 16200 build

in The Rolex Area

Posted

I just harvested a Swiss 2836-2 based 3135 clone looks great for the 16200 build