-

Posts

384 -

Joined

-

Last visited

-

Days Won

1

Posts posted by Rolexaddict

-

-

Excellent write up! So why is the 5.3 crown out? Is there too much space between the REP case lugs?

Yes, that it is,

Its easy to fix a tube and a 5.3mm crown, but the gap is not so important bur enough to disturb the general cosmetic profile

As soon i will have time I will try to reduce this space by adding little stainless steel shim inside and use repushing metal method, or I have also a special stainless steel soft solder paste which flows at 475°F, plus or less 250° Celcius very easy to work

pics of the work in progress and the final result in a few hours

-

Thanks to all for your comments,

tomorrow complete photos of the work in progress and final result after repolishing

-

Gens 1675/16750 case design comparison with 1655 "1/1"

l told I will write something about the 1675 case design and thickeness as the 1655 1/1 is to fat and complete out.

Precision :

This is not a critic, or call it a constructive critic, as the 1655 case is an excellent case, it has a very good potential and will

stay for a long time the background reference to build a 1675 or 16750 rep.

Another precision for those who don't know the difference between a 1675 and a 16750 :

the 16750 is the modern version of the 1675. It has the new 3075 -28.800bph- movement with the quick date set and a different hand

stack by the way. Thats all. No way to ajust the GMT hand. This feature will come with the GMT Master II.

In the real world the Explorer 1655, the GMT Master 1675 and 16750 series use exactly the same case. These cases are very thin. 6542

GMT and early 1675 cases were still thinner !

Our rep 1655 1/1 has a thick case with a global design which is vrong for the purist but really interesting on another way, as its a

good platform to start many projects. For exemple, I would myself use this case to build a 16570 as it has the same thickness

I didn't take a caliper, I have 2 eyes, I observe the real stuff, then I copy. In fact i cannot find again my caliper, probably my wife took it and put in the garbage by mistake, thats life.

Lets see the photos

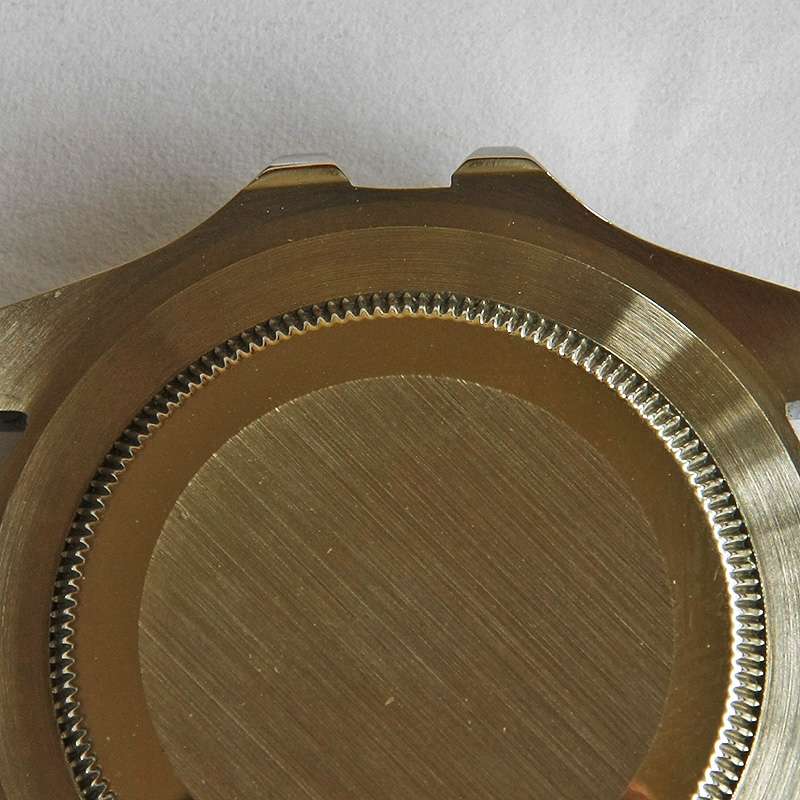

This is a 1655 rep case I am converting into a 1675 for a member. Right now I have just finished to enlarge the lug holes. That is

very common but will not make the watch.

Drilling lug holes and put a GMT bezel does't make the GMT 1675 trick. To build a 1675 which looks like a 1675 and not like a simple rep there is a lot of work to re-design the similar particular 1675 case lines.

The only problem which remains is the crown. On the 1655 rep case the inside space between the crown guards is more important than on the gen : The 5.3mm crown will look to small, so its easier to use the same 6mm crown from the Explorer 16570.

I am trying to find the way, probably by adding metal inside the crown guards. Thats another story.

This is a gen 16750 : observe the profile, the narrow space inside the crown guards, the small 5.3mm crown high positionned and the

bottom crown guards cut.

this is a another gen GMT case, a 16753 (TT) I have worked on, the crown has been removed to show the tube installation which is

machined very high

Now I am holding both the gen 16750 on top and the 1655 rep case. Look the difference. O.K, I told its the double of thickness ,I

admit I was to much categoric, sorry.

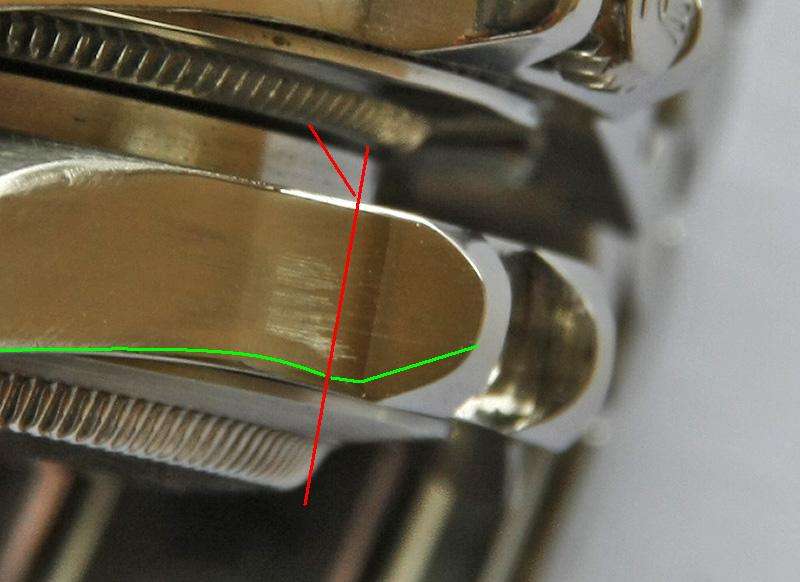

Now compare gen the crown guards bottom area

Here the rep 1655 crown guards bottom area

This is imho the most interesting view, the crown guards profile : on top the gen 16750, bottom the 1655 rep case

You see what I mean ? I think is complete off, no comments.

Another precision : my skin is very dry as I my fingers were in chemical and degreasers, I will put cream later

The other case side is pretty good

So the 1655 case has to be recut at several spots to get this slim design like gen 1655 and 1675 case. For this I recut both sides

and crown guard sides as showed here.

1 : Gaining a few 1/10 of mm inside the crown guards will allow the crown to be recessed, less protuberant. The trick is to don't let

the crown going under the bezel ring, it has to be at the limit.

2 and 3 : This cut will allow to show a more stretched crown guards profile

Here the red line figures the new break angle case side/crown guards side

To finish, a few thousands of material from the bottom of the case is also removed to get the slim thickness

For a comparison, this is a 1675 I have built for myself. On top the gen, bottom my rep. The profile is o.k, the crown is a gen 6mm.

A 5.3mm would look to small.

Again, just drilling lug holes and put a WSO bezel assy will not make a 1675, even with a gen insert, cristal, crown or what else...

TO BE UPDATED IN THE COMING DAYS

To show the work in progress on the 1655 rep case, this will be a very rare and particular 1675 for a member.

-

wait till monday, I will have a gen 16750 and measure with my palmer the case thickness and show you the difference between a gen 16750 case, which is the same case as the 1675 and the same case as the 1655 -talking gen stuff-

Just to show the rep case tickness difference I have actually a Josh 1655 (1/1...) case stripped and ready for machining for a member,

Also a big article in in progress, unfortunately, I do a lot of things at the same time and I am very busy right now

In fact, I don't know why I insist, anyway the gen 1655/1675/16750 use the same case, any years of production, cases are slim, and the 1655 "1/1" is very far from the real stuff. Period. -for me-

-

Are these the correct parts?

24-600 crown

24-602 tube

Where can I get them cheaper? The new ones on fleabay cost an arm and a leg.

Thanks!

you need a tube 24-5330-00

and a crown 24-603

By making evidential claim in my thread...you are claiming to be a 1675 guru...so have you even measured the thickness of the both mid-cases or not???

Yes...your reputation as a claimed 1675 expert is on the line here...

Sorry for having violated you thread, next time I will stay away

What is on the line now here ? I am affraid now,

I never claimed to be a 1675 expert, I am expert of nothing, this is people here who have invented that,

I am not affraid for my reputation

you should keep more retreat,

you should keep more retreat,Also I have nothing to prouve or to defend, just to confirm the 1/1 1655 in not 1/1 and 1675 have all slim cases

the 1655 on the photos is the one from Josh, its the same watch since 2 years and a half, I had dozens, all were indentical

The only right thing, I made the mistake to claim in you thread, I appologize.

-

So just any gen DJ 6mm crown and tube will do?

Any thoughts on the rep folded bracelet? Thanks!

Not the DJ crown, it is 6mm but a little longer, you need a 16570 crown and tube (Explo II)

More evidence that the Josh 1:1 1655 or rep case is not too thick and in fact maybe too thin...

My "oh my god super-de-duper ultra hyper chiman is broke because of it" franken 1655 on top and 1675 constructed from Josh 1655 1:1 on bottom...the rep case thickness looks pretty good to me...maybe a little thin...

O.K, I don't want to start a pissing contest or create a gurus war (I am not in the guru club, I just avoid to take myself to much serious)

I work on gen stuff for collectors shops and privates. I don't compare with Japanese or American literature or web photos, I compare with physical gen watches in front of my eyes and in my hands. Also if some have to drive 10 miles to find a gas station or a fast food, I need 10 minutes walking from my home to find many vintage watch shops

I will show you an exemple, proving the 1655 "1/1" is not 1/1, its to thick. Gen 1655 and gen 1675/16750 use the same case. A very slim case. In fact, he Josh 1655 has probably been built using an 16570 rep case as template.

This 1655 is more close than the 16570 Explorer case. Rolex used same cases for both Explorer 16570 and 16710 GMT Master II.

It would be interesting to build a 16570 with a Josh 1655 with a saphire conversion.

However, the Josh 1655 case remains actually the best background to convert into a 1675

I have found the way to remove metal from the case botton and CG bottom area to get the similar slim 1675 case profile.

I had several 1675/16750 at home last month and took lot of photos comparisons -article in progress-

For now, I compared the 1655 I call now the 0,5/1

with a gen 16570 to show the 1655 is even a little thicker than a 16570 with is a fat case !

with a gen 16570 to show the 1655 is even a little thicker than a 16570 with is a fat case ! Here, I opened the gen, just to check if its no a fake

I put my name also, so no blabla, its my photos

I put my name also, so no blabla, its my photos

Now, profiles comparisons : 16570 on top

Here, profile differences, shorter CG on the rep and to much material bottom

any questions ?

-

Wow! I like it when an old thread becomes active again!

Acutally to correct RA...the 1675 came in many thickness throughout the year of its production (just like the 1016), so the rep case may not be too thick. The Japanese Rolex handbooks are great at documenting case thickness and sizes.

yes and no,

1675 cases have same specs from A to Z

16750 are identic, just later, the transition case, (fat lady) which was thicker

Actualy I work on gen watches, I have made mold from lot of gen cases, ASAP I will post photo comparisons from gen 1675/16750/1655/16570.

General message :

This is a recurrent problem with reps : cases are to fat, please compare with gen stuff in your hand, not only by looking pictures,

Submariners 5512, 5513, 5514, GMT master 6542, 1675, 16750, Explorer 1655 have VERY SLIM CASES IN THE REAL WORLD, yes, VERY SLIM, put a gen and a rep together, the rep has the double of thickness !

Exception for the 1680 and the 1665 which both have fat cases

Now, I have found the way to machine the 1675 case bottoms, I am able to restitute at 90% the exact case profile and CG profile thickness, the only thing I did not yet find a way, is the use of a 5.3mm crown

Member tabularasa is the first one who got the new slim machined case

asap a post with talking photos

-

Sure ! this product is miraculous, it restaure faded painting, lume dots, plexi etc.

-

Is it a must to replace rep crown with gen crown and tube on a 1655 Exp II build or the rep crown is perfectly acceptable?

Some precisions, then I will answer your question :

Its true and verified that the 1675 and 16750 both use the same case than the 1655.

But in the rep world, the 1/1 1655 Explorer is not at all 1/1.

The only 1/1 is you can use a gen plexi and an aftermarket bezel assembly to convert in a 1675. That's all.

The 1655 rep case is to thick : check and compare with a gen 1655 and a gen 1675 the case profile and thickness.

The 1655 rep case has a wider inside space between the lugholes. That means a 5.3mm crown will look to small.

Thats why I recommand to use a 6mm 16570 crown in the rep, for cosmetic reasons.

Answer to yout question :

Yes, your 1655 will look better with a gen 6mm crown as it is thinner than the rep crown and it will completely change the visual effect

-

-

A large cutter blade, a watchmith hammer, introduce the blade between the case and the retaining ring, start at 12 for example, use the hammer (gently) and process at 3, 6 and 9. The ring should lift itself. Of course it takes a little time

-

-

sorry Ephry, I didn't read well, or to fast, (as usual...

) you question,

) you question,About Yuki dials date window, I think the same. Something is vrong, I will say : imho, not small, but misaligned. Or probably both.

-

CGs on these MBWs

need work on the inside and outside.

Cheers

Frank

sounds like now these cases are better in term of specs accuracy

this case concerned don'tt accept a gen dial or a gen specs rep dial without a dial cut or case machining,

for crown guards recut, I prefer to keep a light hand : Visually, it could be ruined very fast. Removing metal its easy, adding is more a problem.

I have seen a gen 1675 initially supposed to have regular CG, so overpolished that CG were looking like a pointed CG Sub 5512...

-

1

1

-

-

Results are good, nice job. I am not clear on some of the items you did for the mods. I would have liked to see before and after pictures of the <ACRONYM title="Crown Guard"><ACRONYM title="Crown Guard"><ACRONYM title="Crown Guard"><ACRONYM title="Crown Guard"><ACRONYM title="Crown Guard"><ACRONYM title="Crown Guard"><ACRONYM title="Crown Guard"><ACRONYM title="Crown Guard"><ACRONYM title="Crown Guard"><ACRONYM title="Crown Guard">CG</ACRONYM></ACRONYM></ACRONYM></ACRONYM></ACRONYM></ACRONYM></ACRONYM></ACRONYM></ACRONYM></ACRONYM>'s to see exactly what was done. For the dial lume, is there a reason why is the lume not smooth? It looks like the lug holes are chamfered on the outside of the lug, is that correct or is it only in the pictures? I have done many of these same mods, but what I am asked to do is quite different than what you are showing. My lume is smooth and puffy, the lugs have no chamfer and the <ACRONYM title="Crown Guard"><ACRONYM title="Crown Guard"><ACRONYM title="Crown Guard"><ACRONYM title="Crown Guard"><ACRONYM title="Crown Guard"><ACRONYM title="Crown Guard"><ACRONYM title="Crown Guard"><ACRONYM title="Crown Guard"><ACRONYM title="Crown Guard"><ACRONYM title="Crown Guard">CG</ACRONYM></ACRONYM></ACRONYM></ACRONYM></ACRONYM></ACRONYM></ACRONYM></ACRONYM></ACRONYM></ACRONYM>'s end up quite thin. It would be nice to know what is correct, or is there a variety that is acceptable. For the lugs holes, every gen I have in the shop has flat edges, no chamfer, and my '63 5508 has nice puffy round smooth lume as do all the other gen's I have seen in the shop. Is there something I am missing or doing wrong? Thanks for the insight...

For the crown guards :

I removed little metal inside -most was burs coming from background machining- Also from the bottom, according with gen cases, this case had to much metal at the crownguards bottom area Then make the outside crownguards just a very little more pointy removing material only by strong high speed polishing using silicon tools. According whith what I have seen, imho its enough,

the gen tube installation need 2 different diameter drills, re-threading, then a cone (chamfer) 3.9mm at the base and 5.0mm on the top

For the lugholes :

I have noticed this on my picture and was sure some will ask : its the picture effect,

lugs were already drilled at 1.2mm, I just made a new pass at 1.3 for a fluid clearance with gen Rlx springbars, no outside case face chamfer

The lume :

This granulous and irregular aspect is due to the products I use. Depending the ratio chemical/medium it can shrinks a little, but its what I wanted and looks like what I observed. Also this result is amplified by the photo light and contrast

-

Are you talking about these rings which suppose to adapt a Rolex dial on a ETA without cut the dial feet ?

no way, and it makes no sense, use a regular brass ring from a rep, and cut dial feet as usual, you will save money ans hassle

I have made some experiments :

Rolex movements are 13 1/2 lines, will fit without difficulties inside the worse Canal Street pot metal Rolex case,

ETA movements are 11 1/2 lines, will fit without difficulties inside a gen or the worse Yuki case, using the rep brass ring

-

I just finished a 1680 for a member here,

- MBK case,

- Gen complete bezel assembly with gen insert and pearl,

- Gen plexi,

- Gen tube and crown,

- Unknow dial origin, but very sharp prints,

re-designed CG,

lugholes re-drilled 1.30 as 1.20 is to tight for gen Rolex springbars,

complete relumed dial, hands and pearl,

movement : ETA 2824.

Enjoy photos

-

1

1

-

-

Here, step by step to disassemble the classic day/date 7750 with 12, 6, 9 subdials

http://pugwash.info/eta/7750/7750.html

the you will need the Chinese modification, allowing to transfer the minutes counter at 3 instead of 12. It consist of a round plate hold by 3 screws, this is a module, with a "bridge"

you need this module, I don't know where you can find it, except if a rep daytona modified 7750 is canibalized

-

WARNING WITH AFTERMARKET OR GEN DWO FOR 5512/13/14, 1675/16750, 1665, 1680...

DW numbers on all old Rolex movements are reversed. On ETA and Asian movements DW turn clockwise, on old Rolex movements it turns opposite.

-

Cyclops mag (if the crystal has one) is, in my opinion, the best way to tell. Having seen many after market plexi crystals, I also feel there's a certain clarity to gen Rolex plexi crystals that aftermarket products lack.

Its true that gens clarity and cyclop are better, also lot of aftermarket collapse or develop micro cracks when pressed on the rehaut wall.

If impossible to source a gen, I would suggest the "new 25-116" from Clark which is the best aftermarket for acrylic formula quality and specs

-

oh, I reconize my document replica...

with my first Corniño built 3 years ago...

I still use strontium aluminate to reactivate dead tritium

like here, on this gen 16753 I have restored for a valuable collector

Thats was my office, zoomed photo taken from my seat flying over Austria, cargo en route from CDG to Mombay

Note : I didnt wear a Rolex GMT, enough clocks on board

-

azgjav,

I apologize, I didn't exprim well my thought, you did a great work, I just wanted to criticized this case with short out of reality crown guards

-

Zk, Mazzariol's blog is great for photos and gives inspiration, but :

Mazzariol is not really a trusted reference, what is true, he is an Italian, we know Italian are good for speeches and spectacular gesticulation, talking with hands

lot of Italian are hanging after Rolex parts worlwide, ebay chitty-crappy Rolex faded parts auctions, lot of books from Italy, full of Italian catalogs of Cosmographs for sale, sounds like Italian archeologs have found a secret Rolex Vintage Watches factory, (yes, in Roswell/USA for sure)

- and may be also the white GMT dial -

also the Coca Cola story and Santa Klaus

also the Coca Cola story and Santa Klausthis white rolex GMT was never confirmed, its a myth, like PanAm pilots using a GMT master, "Oh my god ! fortunately I fly with my GMT Master ! I will know exactly what time is it here or there" advertising showing captains with full gold Rolex... ridiculous

Note : No necessary to post pics with 777 and 747 cockpit with a GMT equiped wrist close up, and to try to impress me with rubbish

I have spent 30 years in heavies flying worlwide, without a Rolex GMT at my wrist

I have spent 30 years in heavies flying worlwide, without a Rolex GMT at my wristjust kidding

-

There is no genuine white dial

I love München Weiss Wurst, confirmed white color by Chef Mazzariol

Weiss Bier also, I love beer

Gens 1675-16750 case design compared with 1655 "1/1"

in The Rolex Area

Posted · Edited by Rolexaddict

All the case design modifications are made by hand in 3 steps : by filing with medium cut files, then machine pre-polished with high speed silicon wheels, then the finish.

The fist jobs for watchsmith apprentices is the hand filing. Get skills and hand precision to cut flat, square and make perfect angular cuts.

Good news : I have found back my caliper , usefull in fact to check regular tickness on a filed flat surface

, usefull in fact to check regular tickness on a filed flat surface

Personally if have spend a lot of my holiday time in Florida with a master gunsmith, and I learn to file and file again... till the job came in my eyes and brain.

Many gunsmithes switched to watchsmithing, or opposite,

These little mods on the case would be possible with a milling machine, may be.

First cut is made to determine the new crown guards and side line using a round file. I use a very thin point permanent marker to trace the way,

The 2 first cuts are done on both sides.

Then the flat cuts

Now in red the metal which must be removed to give this particular crown guards bottom line

And, here we are,

WARNING : finger prints, some toolmarks are still there, its not finished,

After a few time of checking, pre-polishing, checking again.... The result before the ultimate and final check and polishing

Its not completely finished, I have to come back at some areas, achieve the complete polishing, then apply a light patina by hand, using #1200 wet and used sandpaper.

The gen 16750 and the case in progress (not yet finished)

The problem is still the 6mm crown, this will be the next challenge, adapt the 5.3mm crown