-

Posts

2,186 -

Joined

-

Last visited

Everything posted by rolli

-

Rolli's FGD - 004 PreA Marina Dial Artwork in Swiss Oem Quality

rolli replied to rolli's topic in The Panerai Area

-

Rolli's FGD - 004 PreA Marina Dial Artwork in Swiss Oem Quality

rolli replied to rolli's topic in The Panerai Area

great work, complimant, that is a really beautiful eye catcher all the best rolli -

dear kilowattore, i've studied this making and all the mods over several years, already when we started on this rwg forum 2006, a small circle of hardcore members worked already on mods. pre vendome moddings was always the first premise for pams till today. and i am so happy that you have reached your aim. all the best rolli

-

amazing result, compliment for that awesome fine work. all the best rolli

-

Rolli's FGD - 055 Rare Dial in Swiss Oem Quality and Standard:

rolli replied to rolli's topic in The Panerai Area

pam 061 caseset is the better option rolli -

Finally a good PVD option... My 203/A is "done"

rolli replied to Grimlocktime's topic in The Panerai Area

great pvd work and case work. compliment. note: the Rolli-FGD OEM Dial will come !!!!!!!!!!! all the best rolli -

maybe noob bezel has the same bezel construction. only the qestion with the bezeö gasket weather it fits on the jimmy Fu mid case collar. otherwise you could glue the bezel also with a 2 component dlue on this mid case collar. if you get a steel bezel, write to grimlocktime about the pvd or dlc coating. you also could ask member olreon here, in the past he had some jimmy Fu bezels extra. regards rolli

-

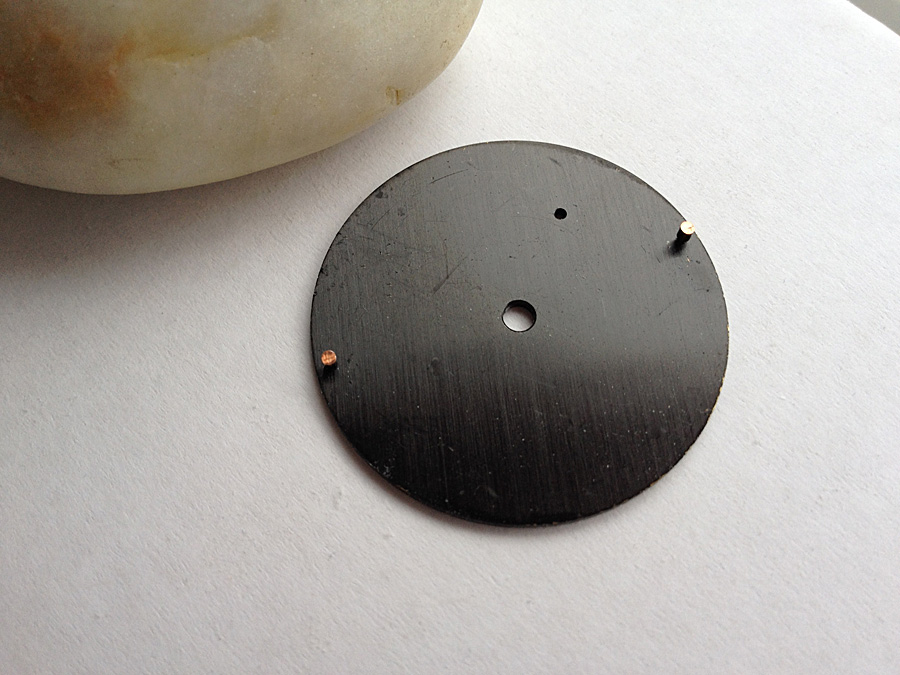

Rolli's FGD - 040 Marina Dial Artwork in Swiss Oem Quality: here we introduce a more than rare artwork 040 Marina dial in swiss oem quality and standard. made by a high grade oem swiss dial maker, made in switzerland. the oem standard and oem rules say, only to use high end materials and high grade machines, made in switzerland. materials only from swiss companies which also are developer for the well know products for the watch making, also the machines, cnc machines from almac swiss, absolutely fast runner with 5 independent spindles and perfect for recessed indices milling and for all dial applications, also for movement parts etc. all watch brands with in house production factory work with this special swiss almac cnc machine. all our dials were made on this machine. all the swiss oem dial maker have an expensive high grade machine park and be guided by ingineure. basic material is finest brass alloy , punched to a round plate with 1,0 mm and welded the unitas 6497 feet. indices cnc machine milled, processed the surface to a thickness of 0,97 mm. and then on the surface the fine glass beads blasting, after the cleaning process and the black galvanic process. for the final finish was applied the zapon varnish with satin sheen finsih. now the dials have a final thickness of 1,0 mm. note: all indices numerals shape have the typical pre vendome features, see the lower sharp corner in the contour on the 6, and the preV typical numerals shapes. PreV Style indices milling: all indices numerals contours were pre-milled with a 0.1 mm milling cutter, so that the sharp corners in 6 could be made, after with a 0,4 mm milling cutter were milled the inner rest. it was only possible with a special swiss almac cnc machine, and necessary a special pre working and programming on the cad program. a very elaborate cnc machine procedure. note: all PreV and all preA and 040 dials have this special numerals feature on the shape contours. now the dials went to swiss rc tritec for our special tritium look. last year we developed a tritium simulated high grade super luminova color, 10 years burned out look. rc tritec switzerland analyzed this color and produced it in triple high grade-A super luminova a special color for us. i could buy the original old stock tritium resin varnish UV820 from rc tritec, which was still in stock from 1993 and i could buy the rest stock. the tritium high glossy resin varnish uv820 is the original which was used for all tritium mixes , and as protection against the radioactivity. all indices are filled with this mixture by swiss rctritec employee by hand with the stylograph in the typical recessed preV style filling. the preV fgd hands are special made for us including the small second hand including a longer second hand tube, are also filled by rc tritec with a non matched high grade-A tritium simulated super luminova. after this process the dials went to the swiss printer, for the print steel cliché, and for the final lettering print, also with swiss berlac paint in high glossy peal white. this was a small introduction to the oem manufacture, i already studied for years all these single procedures and steps and could train and instruct the dial maker for the important details, also i trained the engineer and graphic designer for the vector graphic on auto cad for all the important sensible details. we had a genuine dial and high resolution scan all the time as basic for the profuction. For more Details please send a PM regards Rolli

-

Rolli's FGD - 001 PreA Marina Dial Artwork in Swiss Oem Quality

rolli replied to rolli's topic in The Panerai Area

-

Rolli's FGD - 004 PreA Marina Dial Artwork in Swiss Oem Quality

rolli replied to rolli's topic in The Panerai Area

-

Rolli's FGD - 055 Rare Dial in Swiss Oem Quality and Standard:

rolli replied to rolli's topic in The Panerai Area

-

New Batch Rolli's 5218-210 Yellow Dial in Oem Quality and Standard

rolli replied to rolli's topic in The Panerai Area

-

Rolli's FGD - 004 PreA Marina Dial Artwork in Swiss Oem Quality

rolli replied to rolli's topic in The Panerai Area

many thanks rolli -

Rolli's FGD - 004 PreA Marina Dial Artwork in Swiss Oem Quality

rolli replied to rolli's topic in The Panerai Area

more pictures attached regards rolli -

Rolli's FGD - 055 Rare Dial in Swiss Oem Quality and Standard:

rolli replied to rolli's topic in The Panerai Area

-

New Batch Rolli's 5218-210 Yellow Dial in Oem Quality and Standard

rolli replied to rolli's topic in The Panerai Area

-

Rolli's FGD - 004 PreA Marina Dial Artwork in Swiss Oem Quality

rolli replied to rolli's topic in The Panerai Area

-

Rolli's FGD - 001 PreA Marina Dial Artwork in Swiss Oem Quality

rolli replied to rolli's topic in The Panerai Area

-

it is only for real enthusiasts amazing look regards rolli