-

Posts

267 -

Joined

-

Last visited

Posts posted by Grimlocktime

-

-

The gen dial is the hard part. I recommend the noob PAM104 as a base for a closed 6 build. Or an H Factory PAM090I for the more rare open 6 version, which I built recently. I sent you a PM for more info on this topic

-

On March 20, 2016 at 5:30 PM, hugop said:

Yes it is but where is your pic?

You don't want to know... I made a rash decision:/

good news is there might be another couple of beautiful Rolli FGD dials that come up for sale;)

-

1

1

-

-

Today's a good day for tobacco.

-

On March 8, 2016 at 4:21 PM, hugop said:

Just beautiful work as usual M! Congratulations on finally achieving this long term goal. Well done!

Hahaha you know first hand that I've been after this for years!

On March 8, 2016 at 4:23 PM, AGONZCA said:You just saved yourself about $45K congrats my friend

15 hours ago, rolli said:great pvd work and case work.

compliment.

note: the Rolli-FGD OEM Dial will come !!!!!!!!!!!

all the best

rolli

It can't come soon enough. Your dials are amazing. I'll have to find some time to post some comparison pics between your dial and the gen dial. I know you say that your dial matches the genunine production process, I can assure everyone that these are not false claims. its obvious when held side by side. Keep up the good work Rolli!

-

Those dials.... Wow. As one of the very few people to have actually held a genuine Pre-V dial next to Rolli's... I can say for certain that they are identical in terms of how they are made. Congratulations on your beautiful dials.

-

The watch that launched me on my journey to obsession/madness/watch building was the 203/A.

There is just something that resonates with me when I see the contrasting black dial with aged cream colored tritium. And the iconic tan strap against the anthracite colored PVD.... Oh yes... The PVD. That's the one feature that's been hardest for me to get nailed down. Noob still makes great cases that can be reshaped. DSN makes amazing crowns and acceptable CGs. Rolli is constantly producing great dials. There are lots of great caseback options, but the PVD... What to do?

Since affordable European sources have dried up all that remains is spending upwards of $1000 for a decent PVD job. So, over the last 2 years I have been trying to work with existing shops to get a decent price on a coating with all the required nuances. The finish should change color based on the lighting. In most outdoor conditions you'll see the classic pencil lead color emerge with a nice contrast of charcoal. On dark days and low inside light, the watch will almost look black Just as important as the anthracite finish is the surface preparation. The case must be bead blasted with the appropriate fine media to achieve the special shimmer that makes the case glow under the finish. Seems easy, right? Not really, not for a decent price. That is until recently when a friend put me in contact with a friend who I was able to work through a few iterations to get the finish just right, in my opinion anyway...

the specs on this build:

Noob 111M reshaped by me

Gen crown with custom tube

WSO gen correct double screw bars

BM C3 Crystal

Southy museum grade dial (only 2 in existence)

Jakob caseback

Swiss 6497

And on this one, a very special strap... A genunine Pre-V PAV99 with a 22mm buckle

The journey was long but worth it in the end!

-

2

2

-

-

Awesome post Kilo!

You say it all, but Let me try to add to the bottom line. When I built the franken 36B for Agonzca, I had the opportunity to have the. genuine 36B dial side by side next to Rolli's

the color is identical

the text is actually cleaner and more crisp on the Rolli dial

the lume application is more cleanly done on the Rolli but matches the gen almost exactly.

the overall quality would lead me to believe the Rolli dial is a NOS tritium service dial, even though I don't think those exist. Extremely amazing. Probably the best dial he has ever made. You are lucky to own such a great piece. Congrats!

by the way, if you ever decide to upgrade to the Hfac case, I know some people that could add the engraving. Also, there's rumors that a 1:1 caseback is being crafted by a certain caseback maker we know;)

-

happy new year to you Rolli. Looking forward to more great projects!

-

Another astounding effort Rolli! Congratulations!!!!

-

Once again, I'm so glad you're happy. I can't tell you what a pleasure it was to hold these parts and study them up close. I have to say, I was stunned how close the gen dial is to Rolli's. If anyone here owns a Rolli dial, consider yourself lucky. But, not quite as lucky as AGONZCA. ;)

-

Ha! Glad I could help. It was fun playing with all those parts.

-

Beautiful pieces. I'm glad you're enjoying them! It seemed like a long time but in the greater scheme, it used to take years to assemble watches of that caliber. You did it in months.

-

Congrats my friend! Wear it with pride. That is a gorgeous watch with a fantastic movement! Enjoy!

-

The PAM036B was originally sold with a tritium dial. In the proceeding years a few people have sent their watches in for service and had them replaced with Luminova service dials. If you see a 36B L SWISS L dial it is in a watch that has been sent for service. Like this one below...

side by side: Tritium versus Luminova (Tritium is better LOL)

-

This is real. The CG was likely replaced when the luminova service dial and hands were installed, explaining the potential mismatch.

What a shame to put a luminova dial on such an iconic watch.

-

1

1

-

-

The PAM222 is an excellent base for a PAM086. The crown and tube are very accurate and require no modding. The overall caseshape is very good.

You just need a good CG and a DSN caseback and your case will be ready.

-

I use homage/parnis/marina militare sandwich dials. They go for 5-10 usd each shipped.

Carefully separate the two layers with a blade, scrape off the lume and eventually make the plate a bit thinner by rubbing it on sandpaper.

they are too thin. You will have issues unless you build up to the correct thickness. It is critical that the dial plate is held tight against the dial recess under the rehaut.

The best option is a noob or h factory sandwich dial backplate.

-

1

1

-

-

Stunning Rolli! Congratulations on ANOTHER amazing dial. Beautiful!

-

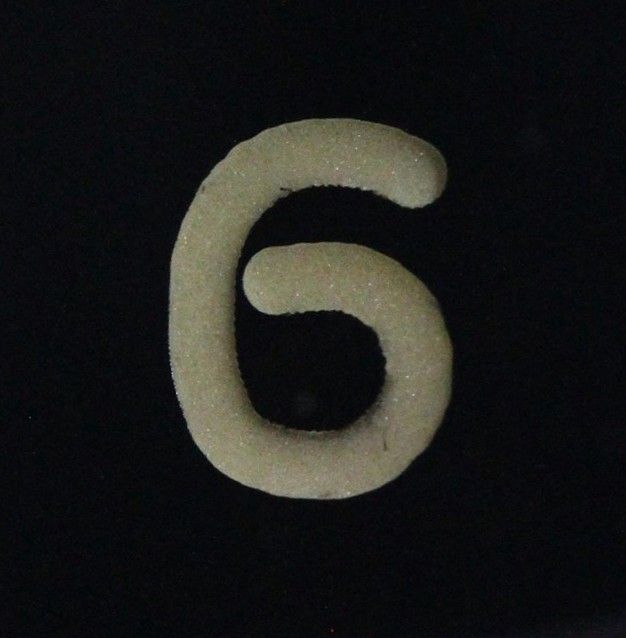

To me the above image looks machined, not stamped. You can see the chatter of the cutter and the slight wavy path, particularly at the inside tip, and at about 10 o'clock as it comes up around to the top, caused by the sheet material moving slightly. The picture Pete has is of more contemporary dials, which were higher volume production, where it made sense to make tooling. The Pre-Vs were low volume, it made more sense to pay a higher part price but not have to pay for tooling, they were only selling small batches.

This would mean that the variation in indice thickness is easy to explain, every time they did a batch they had a different cutter, possibly even replacing them within batches. You are talking less than 0.1mm between a 'thin' indices dial and a 'thick' one, so cutter wear, cutter tolerance, or even 'Damn, broke a 0.7mm cutter, have a 0.8mm, it'll do, no one will notice' comes into play. Small company QC in Italy for tool watches, not Swiss luxury QC...

Factor in 'painting over the lines' and thickness tolerance goes haywire.

Another thing that is interesting on thick indice dials: sometimes you can see where the cutter goes from the top of the '6' in towards the middle, and gets so close to the edge it leaves a tiny sliver of metal, which gets pushed slightly into the vertical part of the 6. Couldn't be done by stamping, and shows they machined the '6' and '9' from the outside in...

D, I feel like an idiot now after reading this... Of course! That's it! The rough edge appears to be from milling, not stamping. So that's probably the difference... Some Pre-V dials may have been stamped and some later versions milled. Awesome!

And by the way... It was a rare opportunity to hold your dial next to the gen Pre-V... All I can say is wow! Beautiful work my friend. I can't fathom the skill required to get the details so close. Thanks again.

-

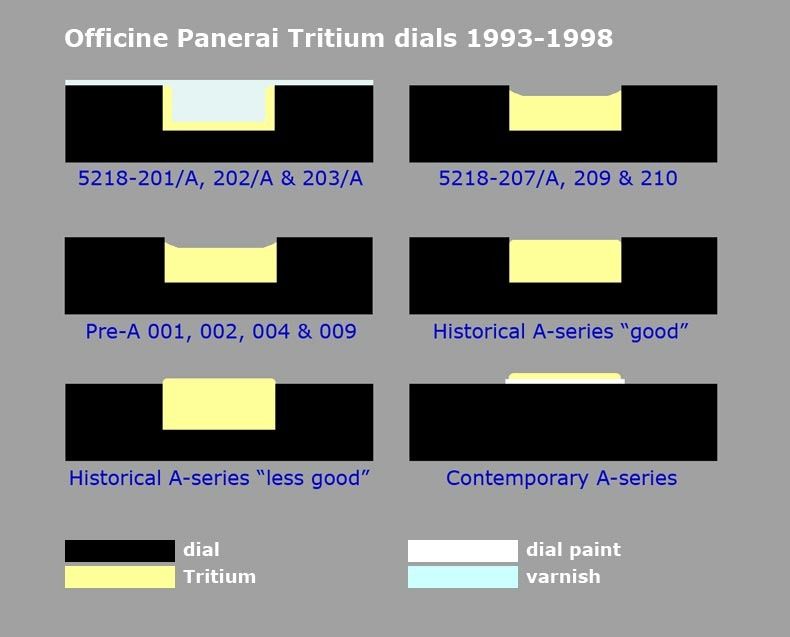

Its a can be a bit of a misnomer or perhaps misleading to consider these dials as just lacquer filled I say that as it can suggest that its only the indices that recieve any varnish whereas on PreV dials they were always varnished across the dial which of course by definition means the indices would be filled as part of that process...

The reference to fat and thin indices is not a variation of the dial printing but related to the lume applicatiion of the individual dials by the individual lumers and the consistency of the lume as its applied and the way it spreads and/or sits over or under the edfe & height of the indices impression... if you picture the lume sitting below the top of the indices this would give a thin look finish whereas if the lume was to sit over the edges of the indices it would give a fat look to the indices... hopefully that makes sense..

There is plenty of accurate information available on the Risti archives and Thai PAM sites but for example here is a guide on the varnish application on PAMs since PreV and through..

And although these are more modern pics this gives you an idea of the process of ,making the dials

Pete, wonderful post as always! I greatly respect your opinion on this. But hear me out for a second... Isn't it possible that there were different dies? We know for a fact there were different dies at least for the 203/A, on which you find most of the examples of "fat" numbers, although I have seen a few 202/A fat number examples. On the flip side, the thin number dials seem to be primarily seen on the early Pre-V non-matching dials, in both 201/A and 202/A.

I tend to see Pre-V dials that I would classify as thin, medium and fat. It seems reasonable that the medium dials could be thin dials with the effect that you describe. But the fat dials just seem far too different for this explanation to apply effectively. A few years ago when I first read your post describing this visual effect, I took it for face value, but this picture below changed by mind.

In my opinion this shape is structurally different than the typical thin number examples. It's not just an optical illusion from lume application. Note the black space between the main body of the six and the upper hook. Also due to the high resolution of this picture, you can see that no lume is painted up onto the edge.

-

Stunning results Widza. Beautiful watch!

-

1

1

-

-

Sounds like a custom job for a watch smith.

-

Thanks V. Unfortunately I'm only holding this fort the owner while I build his epic Franken. This is one of my dream watches though, so someday, I hope to buy it from him;)

The case is a gen PAM000K that was sent to Germany to the same PVD coating provider as Panerai used in the early 90s. We know it is the correct coating. The documents and receipts prove it.

-

I am in the middle of an epic Franken build for a fellow RWG member. A 203/A with a genuine dial and hand set, reshaped case custom coated by ROLLI's genuine Pre-V source.

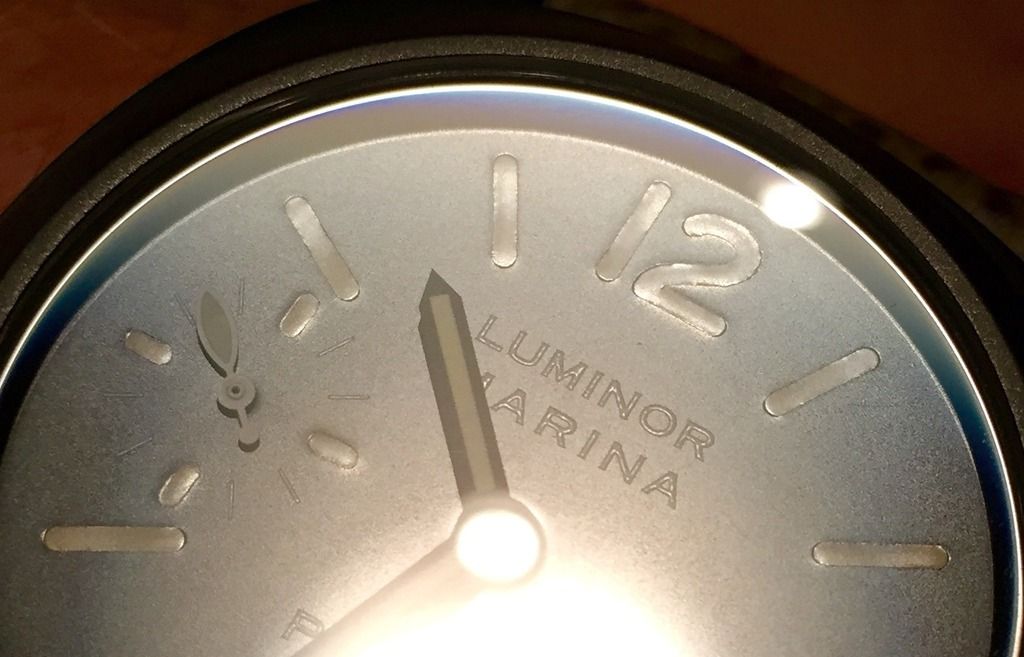

Along the way I'm taking lots of pictures and finding answers to plenty of questions I've had about the structure of Pre-V dials. One of those big question marks was the fact that we know the genuine dials indices are lacquer filled, but I have not found any images to demonstrate it. Furthermore my friend Rolli, has been questioned about this feature on his amazing Pre-V dials... I'm here to answer that question with some photographic evidence...

Much like Rollis dial, when you view the gen straight on, the lacquer fill is not apparent

But when held to the light, the real structure appears...

in other news...

the DSN CG fits the OEM case and the pencil lead PVD is very close. The biggest difference appears to be the surface preparation before coating. The OEM case shown here has a proper Pre-V coating. You can see the difference versus the DSN CG

and finally the OEM dial versus the Southy Pre-V Museum Grad WOW.... Congrats to Southy

franken millemetri bronzo

in The Panerai Area

Posted

Wow.... Just Wow!

A genuine MM dial? You are a lucky man to have sourced this. Congrats!