When you buy through links on our site, we may earn an affiliate commission.

-

Posts

69 -

Joined

-

Last visited

Everything posted by DocRaph

-

Hmmm... Always order mine through Amazon. Always get it discount. Never any problems with delivery. They do usually have older versions in stock through some of their market dealers. Have a Happy Easter.. Cheers, DR

-

I also have no problem viewing on my iphone - just select the manual option. Interesting about Opera... use it all the time on the Mac.. Wonder if there's an Opera app for iphone - will have a look. Happy Easter all. Cheers, DR

-

OK...thinks.. Been wearing this.. But thought would balance out with this... OOps, too light.. try this... Oh dear...can't decide... Happy Easter all. Cheers, DR

-

Found the Tantalum wedding rings in a small jewelers shop near to where I live - have seen odd bits of jewelry on my travels. Try this link http://www.smart-elements.com/?arg=joy. They did not make a Tantalum wedding ring in my size, so had to make do with white gold and diamonds, however one of my work colleagues (plating shop manager) has one - interesting and really heavy. Cheers, DR PS - got a 111H but the crown and guard look wrong - too skinny - what's the best source of replacements - rest of the watch seems OK.

-

According to the Panerai Special Editions book the bezels on both 172 and 192 are polished Tantalum, cases are brushed Tantalum, and case backs brushed Titanium. Interesting, images of the 192 shows the crown protector polished on the front and brushed on the back???? Thinking about the weight, I agree the 192 would be the easiest to add weight to as it has a solid case back - but does anybody make a rep of this model? The alternative would be to get a steel case Ti(CN) Titanium CarboNitride coated mid to dark grey - it's a PVD type treatment (Plasma Vapour Deposition - think???) There should be any number of engineering tool suppliers who could get it done - just let them know the colour.....just a thought. Using steel would allow the polished bezel as well. You would still need to think about adding a bit of weight, but not as much. Catch you later.. Cheers, DR

-

Looking at using heat to color Titanium - came across these links:- http://www.hollygage.com/pages/adding_color_to_titanium_with_a_torch.html http://www.artmetal.com/files/imported/project/TOC/colorRMS.html Further to my mention of heating in Nitrogen, I did come across some notes I made - By heating the Titanium up to approximately 1,200 degC (2,192 degF) in a furnace with Nitrogen purge and in the presence of Carbon, a dark grey coating of Titanium Carbo-Nitride will be formed. Short exposure times give a gray coating, longer exposure gives a dark gray coating. This is the same material that is vapor deposited on knives, etc as a tough protective layer. Which also reminds me - if you keep on heating Titanium, just in air, you will see the colors change as the oxide layer gets thicker, until it reaches gray, when it will stop - that is the maximum thickness of the oxide. If you need to try for a different color just polish the oxide layer off and start again. (Exactly the same as anodizing). Cheers, DR

-

+3 Keep on collecting...and posting Cheers DR

-

what do you guys think of 'designer' watches

DocRaph replied to numptyj's topic in General Discussion

All you pay for with the 'Designer' watch is the brand name and very little more. And it's not just the High-street' designer brands (those associated with clothing and perfume, etc~) that use cheap movements and materials, but some of the non-manufacture watch makes as well - you don't need me to tell you who I mean. Mark-up on all designer gear, clothing, jewelry and watches is 100% plus tax over trade cost, and you can imagine the sorts of profit the traders make.... I found out about this sort of stuff helping a friend out who owned a sports clothing store. He was having computer problems at the time. Although the store was supposed to be sports clothing, more than 80% of his trade was 'Designer' sports wear - he admitted that without it he would have been in deep financial trouble - real sports gear is in a sad decline....... Now I could buy gen watches (have done and have a few), but I now have a couple of reps, and as far as I am concerned they are just as good to me as the gens - I don't need to prove anything to other people and I wear what I want without having to 'flaunt' it, for my enjoyment alone. Sorry to rant on... back to browsing... Cheers, DR -

Hum... since when has the shortened version of the name Richard been a censored word. I grieve for all of you on this Forum stuck with that name..... DR

-

Just to throw something else into the mix folks; For a lot of years at work I managed the network and PC's in my labs - built all the 'control' PC's, installed software, drivers, etc and fixed them when they went wrong - quite often. When I left that particular job (of 28 years) I got a little bit of money - bought a few things, including a Macintosh Powerbook G4 - that was in Feb of 2004 - guess what I'm still using at home now (in fact this very second) ........ the same machine. In all this time, I've upgraded every second issue of OSX, added a 1TB external drive for storage, and had abso-piggin-lutely not one problem with it!!!!! It's a nice rest when I get home after the frustration of using PC's at my new job - luckily I don't have the responsibility these days of keeping the work PC's running. Now I'm not a dyed in the wool raving Mac-ite - I'll use any tool at hand irrespective of make or system - Windows, OSX, Unix, Linux what have you. It's just that I've managed to find a tool that works for me at home with no problems. If Microsoft made the hardware as well as the operating system, then you would have the same sort of stability as Mac has. There is nothing specifically wrong with Microsoft Windows - it's just that it is expected to work on every Tom, [censored] and Harry's hardware - and considering that, it actually doesn't do that bad a job. Have fun... whatever you are using... Cheers, DR

-

How about a pen with watch components: Made by Caran d'Ache to symbolize Swiss watchmaking - only 500 made, and yours for a cool $19,000.00 each. Cheers, DR

-

Sorry aboput the pics - they are from the Special Editions brochure, but I only scanned them at 300dpi, which results in the cross hatching. I've seen Tantalum jewelry which has been oxidized and contrast polished (nearly bought a Tantalum wedding ring), and the oxide is dark gray rather than blue grey, however the polished Tantalum certainly has a bluish tinge to it under certain lighting conditions- much more so than Titanium You're correct about the machining. Titanium is an absolute sod to machine, and Tantalum is about 10 times worse, so putting a fine thread on Tantalum is asking a bit much. Just thinking......even if you get the color correct.......what about the weight?????? Titanium has a density of 4.5 g/cc. Tantalum has a density of 16.4 g/cc ... 4 times heavier. Just for comparison, Gold is 19.3, Iron is 7.9, Lead is 11.3, Nickel is 8.9, Palladium is 12.0, Platinum is 21.5 and Tungsten is 19.3. Stainless steel is between Iron and Nickel. I suppose you could use a 'look but no touch' policy, or put a really heavy bracelet on it..... Have fun... Cheers, DR

-

I've just had a look at my Panerai SE1997-2007 book. In it are both the PAM172 Luminor Tantalum and the PAM192 Chrono Tantalum. Both have brushed Tantalum cases, polished Tantalum bezels, but they also both use brushed Titanium case-backs, exhibition for the Luminor and solid for the Chrono. As you can see, there is only a very light difference between the brushed Titanium and brushed Tantalum, with the Tantalum being ever so slightly darker. As long as you manage to get a darker grey for the case by anodizing than the brushed Titanium back, all should look correct. To maintain the difference, just keep the back brushed clean of thick oxide layers frequently, preferably with it removed so that you do not accidentally polish the case. Coincidentally, one of the options I looked at for my project was Titanium Nitride coating - heating the Titanium up in a Nitrogen filled oven can give you a nice dark gray layer of Titanium Nitride, which is much harder than the Oxide (also the reason why I didn't pursue it- we wanted to find wear by color change - not no wear). Might be worth considering if you can get access to an oven with a Nitrogen purge. Cheers, DR

-

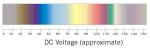

I'll get the reduced report on Monday when I'm back at work, however from my notes at home I have an image which shows pretty well what I got color-wise. From it you can see that grey appears below 10 volts DC, between 60-70 volts DC, then finally at above 150 volts DC. The color that you see from the anodizing is directly related to the thickness of the oxide layer, which is translucent and refracts the light by different amounts - a bit like oil on water. Naturally occurring Titanium and Tantalum oxide layers will be fairly thin. They will build up in time until they totally cover the exposed metal, then prevent any further oxidation to take place - that is why it goes grey and stops. When you anodize these metals, you actually force the layer to be thicker to get the colors. To get an accurate aging color you will need to either anodize below 10 volts DC, which is quite difficult to get as you need to get the potential difference across the volume of electrolyte to get the process going. I found with a large container the minimum at which I could get anodizing to work was about 12 volts DC - which gives a straw color - I can see where brushing would be useful in this case. The alternative would be to anodize above 150 volts DC (risky-ouch), where you will also get a gray color. (60-70 volts DC gives a sort of blueish-gray) This is the oxides' maximum thickness and it is pointless trying raise the voltage past this point as it does not change any more (I went up to 250 volts DC) Catch you later, DR

-

When I was researching anodizing techniques I came across absolutely lots of references. Try this one - http://www.popsci.com/diy/article/2005-06/titanium-technicolor. Or just Google 'titanium anodizing cola' to bring up tons of info. I've found the report I did and am cutting out some of the data and images to post - got to be careful I don't let any company sensitive stuff get out. I've also got hold of some more Titanium (not so easy to get it in the UK - really expensive!), so I'm going to play around with the anodizing a bit more - will let you know how it goes. Cheers, DR

-

Hi, I had a project at work recently, where we wanted to use anodizing on Titanium parts to use as a wear indicator. The theory was that since the color you see is related to the thickness of the oxide layer, as the oxide layer wore down then the color would change. That was the theory - getting it to work was a lot of work. First the electrolyte - we tried borax, sodium tri-phosphate and even Coca-Cola. They all worked pretty well. The depth of the oxide layer which gives the colors is controlled by voltage and not current, so we hooked up a couple of lab bench power supplies to give us the total range of voltages required (I'll look at my notes at work tomorrow and let you know what voltage gave what color). For both anode and cathode we used Titanium mesh, to give plenty of surface area, and also to rests the test piece on. The first problem encountered was the surface finish of the Titanium - we tried polishing first, which is extremely difficult due to the softness of the metal causing it to 'gall' with the fine polishing particles. Got a polished surface eventually - gave very washed out colors when we anodized. We then tried a rough brushed surface - much better, but highlighted the brush lines. Grit blasting - fine grit gave a matt surface which gave a very good result. Acid etching gave us the best result, but the mixture of acid is not something I would recommend outside a lab (includes phosphoric acid!) After we anodized some parts we started wear tests - in general use the anodizing scratched off in places long before we saw a color change - oh well.....idea abandoned (but not the equipment and chemicals - at some point I will dabble again). Did come across an article when we were researching technique, which involved Coca-Cola, a 9-volt battery and a paint brush - apparently it worked!!! We did consider heat as well, but you need extremely good temperature control in an oven with no temperature gradient or air movement or you will get a range of colors on any surface larger than a square centimeter. Have fun experimenting (Titanium is much cheaper than Tantalum but apparently easier to anodize - the range of voltages is not as high). Cheers, DR

-

Cheers, That was really helpful. Also read the review on the Asian movement posted by the Zigmeister - nothing is ever as simple as it first appears... I'm getting another 036 shortly - more like the original with Tobacco face. Don't know what movement yet but the pictures show it looks incredibly like the factory gen pictures.. we'll see - I'll post some pics when I get it next week. I want to do something different with this PAM and customize it a bit. Saw a very nice gold plated skeletonized ETA 6497 with blued screws on the ofrei website for a very reasonable price and which would look very nice inside the exhibition back of the PAM. Fit a nice black alligator strap to match the black face and ...bingo. At some point it would be nice to find a sandwich dial that I can customize (as per another post I found - this forum continues to astonish me with the depth of articles included!!) Ah well... Cheers, DR

-

What are the tell-tales which differentiate between the Swiss 6497 and Asian version? I have heard that the Asian is noisier when winding. This one is sweet as a nut, quiet, keeps time to 5-10 secs a day, and runs for over 2 days on a full wind. Cheers, DR

-

OK, Here are a few more pics (hopefully I haven't scaled them down too far)... First, taken by Cats :- Then with bracelet:- Right.... off to the sales section.... Cheers for now, DR

-

Cheers, I'll add a couple more pics later - sorry about the bracelet pic - made a radical mistake with Paintshop getting it smaller - went tooo far!!!?? Busy getting some pics of a couple of reps ready for the sale area - need to check I didn't make them too small as well - oops!! Catch you on the rebound... Cheers, DR

-

Of course it could be a 118 - all that's missing is the LE number on the case back - difference with the 118 is movement is a Swan neck, unlike the 036 which uses the original Unitas shape bridges - don't really mind as I have a project plan for it - more later. In the meantime I have a possibility of getting a Tobacco faced PAM 036, which is more true to the real deal. Found a bracelet in my box of bits which I've tried on it..... At the moment the bracelet is mixed polished and brushed - would be better if I change it to all brushed maybe?? Cheers, DR

-

Well... here we are.. First PAM on my wrist, an 036, care of Cats. Amazed by how comfortable it is. Seems lighter than my Omega Seamaster and a lot lighter than my Seiko Orange Monster! The strap is a little short, however I'm organising a swap at the moment, and hope to buy a couple from Panatime later this month. I'm definitely hooked now, and already looking for more..........found another 036, looking at a Vespucci, or maybe a Black Seal....oh dear. Thinks... need to sell swap a couple of gens......addiction setting in..... Cheers, DR

-

Oops, sorry.... must have used a [censored] word -honestly - was in my dictionary??? Cheers, DR

-

I wear glasses as well - headband for general close work, glasses mounted loupe for very close work. Also managed to 'rescue' 2 stereo inspection scopes from work some time ago, which I use for extremely close work. Got the best one stripped down to clean and re-grease, but I'm not looking forward to putting it back together again - parallax is a [censored] to get correct. Cheers, DR

-

I wish this PAM proto had gone into production...

DocRaph replied to projectologist's topic in The Panerai Area

According to the Panerai literature the Black Seal "reproduces the design of the first historic watch created for the Royal Italian Navy in 1938". Because of its high water resistance it was used by the naval divers, nicknamed 'the black seals' because of the black rubber diving suits. Don't know about all that, but they are nice looking watches. Cheers, DR