-

Posts

2,186 -

Joined

-

Last visited

Posts posted by rolli

-

-

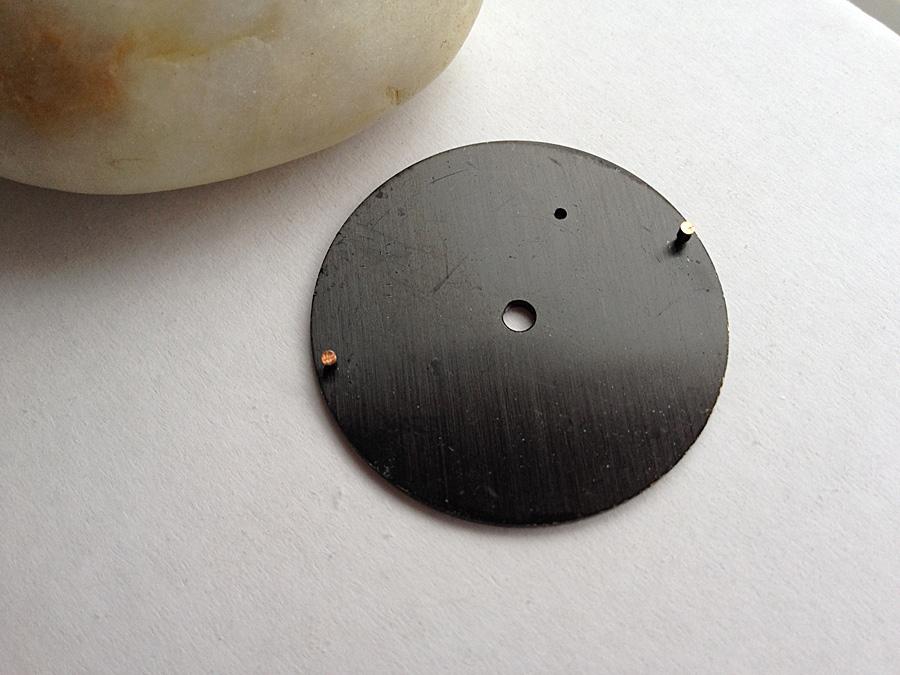

Specifications:

Rolli's FGD - 205A Submersible Slytech PreV Dial Artwork in Swiss Oem Quality:

here we introduce a more than rare artwork 205A PreV Submersible Slytech dial in swiss oem quality and standard.

made by a high grade oem swiss dial maker, made in switzerland.

the oem standard and oem rules say, only to use high end materials and high grade machines, made in switzerland.

materials only from swiss companies which also are developer for the well know products for the watch making, also the machines, cnc machines from almac swiss,

absolutely fast runner with 5 independent spindles and perfect for recessed indices milling and for all dial applications, also for movement parts etc.

all watch brands with in house production factory work with this special swiss almac cnc machine.

all our dials were made on this machine.

all the swiss oem dial maker have an expensive high grade machine park and be guided by ingineure.

basic material is finest brass alloy , punched to a round plate with 1,0 mm and welded the unitas 6497 feet.

indices cnc machine milled, processed the surface to a thickness of 0,97 mm.

and then on the surface the fine glass beads blasting, after the cleaning process and the black galvanic process.

for the final finish was applied the zapon varnish with satin sheen finsih.

now the dials have a final thickness of 1,0 mm.

note: all indices numerals shape have the typical pre vendome features, see the lower sharp corner

in the contour on the 6, and the preV typical numerals shapes.

PreV Style indices milling: all indices numerals contours were pre-milled with a 0.1 mm milling cutter,

so that the sharp corners in 6 could be made, after with a 0,4 mm milling cutter were milled the inner rest.

it was only possible with a special swiss almac cnc machine, and necessary a special pre working and programming on the cad program.

a very elaborate cnc machine procedure.

note: all PreV and all preA dials have this special numerals feature on the shape contours.

now the dials went to swiss rc tritec for our special tritium look.

last year we developed a tritium simulated high grade super luminova color, 10 years burned out look.

rc tritec switzerland analyzed this color and produced it in triple high grade-A super luminova a special color for us.

i could buy the original old stock tritium resin varnish UV820 from rc tritec, which was still in stock from 1993 and i could buy the rest stock.

the tritium high glossy resin varnish uv820 is the original which was used for all tritium mixes , and as protection against the radioactivity.

all indices are filled with this mixture by swiss rctritec employee by hand with the stylograph in the typical

recessed preV style filling.

the preV fgd hands are special made for us including the small second hand including a longer second hand tube,

are also filled by rc tritec with a non matched high grade-A tritium simulated super luminova.

after this process the dials went to the swiss printer, for the print steel cliché, and for the final lettering print,

also with swiss berlac paint in high glossy peal white.

this was a small introduction to the oem manufacture, i already studied for years all these single procedures and steps

and could train and instruct the dial maker for the important details,

also i trained the engineer and graphic designer for the vector graphic on auto cad for all the important sensible details. we had a genuine dial and high resolution scan all the time as basic for the profuction.

For more Details please send a PM

regards

Rolli

-

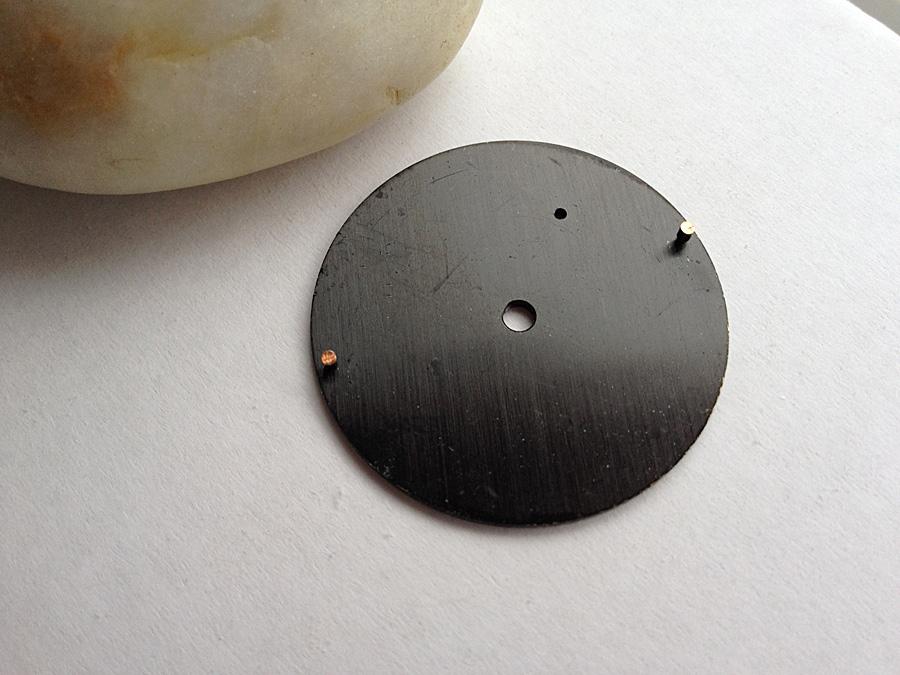

Specifications:

Rolli's FGD - 218A Black Seal Slytech PreV Dial Artwork in Swiss Oem Quality:

here we introduce a more than rare artwork 218A PreV Black Seal Slytech dial in swiss oem quality and standard.

made by a high grade oem swiss dial maker, made in switzerland.

the oem standard and oem rules say, only to use high end materials and high grade machines, made in switzerland.

materials only from swiss companies which also are developer for the well know products for the watch making, also the machines, cnc machines from almac swiss,

absolutely fast runner with 5 independent spindles and perfect for recessed indices milling and for all dial applications, also for movement parts etc.

all watch brands with in house production factory work with this special swiss almac cnc machine.

all our dials were made on this machine.

all the swiss oem dial maker have an expensive high grade machine park and be guided by ingineure.

basic material is finest brass alloy , punched to a round plate with 1,0 mm and welded the unitas 6497 feet.

indices cnc machine milled, processed the surface to a thickness of 0,97 mm.

and then on the surface the fine glass beads blasting, after the cleaning process and the black galvanic process.

for the final finish was applied the zapon varnish with satin sheen finsih.

now the dials have a final thickness of 1,0 mm.

note: all indices numerals shape have the typical pre vendome features, see the lower sharp corner

in the contour on the 6, and the preV typical numeral shapes.

PreV Style indices milling: all indices numerals contours were pre-milled with a 0.1 mm milling cutter,

so that the sharp corners in 6 could be made, after with a 0,4 mm milling cutter were milled the inner rest.

it was only possible with a special swiss almac cnc machine, and necessary a special pre working and programming on the cad program.

a very elaborate cnc machine procedure.

note: all PreV and all preA dials have this special numerals feature on the shape contours.

now the dials went to swiss rc tritec for our special tritium look.

last year we developed a tritium simulated high grade super luminova color, 10 years burned out look.

rc tritec switzerland analyzed this color and produced it in triple high grade-A super luminova a special color for us.

i could buy the original old stock tritium resin varnish UV820 from rc tritec, which was still in stock from 1993 and i could buy the rest stock.

the tritium high glossy resin varnish uv820 is the original which was used for all tritium mixes , and as protection against the radioactivity.

all indices are filled with this mixture by swiss rctritec employee by hand with the stylograph in the typical

recessed preV style filling.

the preV fgd hands are special made for us including the small second hand including a longer second hand tube,

are also filled by rc tritec with a non matched high grade-A tritium simulated super luminova.

after this process the dials went to the swiss printer, for the print steel cliché, and for the final lettering print,

also with swiss berlac paint in high glossy peal white.

this was a small introduction to the oem manufacture, i already studied for years all these single procedures and steps

and could train and instruct the dial maker for the important details,

also i trained the engineer and graphic designer for the vector graphic on auto cad for all the important sensible details. we had a genuine dial and high resolution scan all the time as basic for the profuction.

For more Details please send a PM

regards

Rolli

-

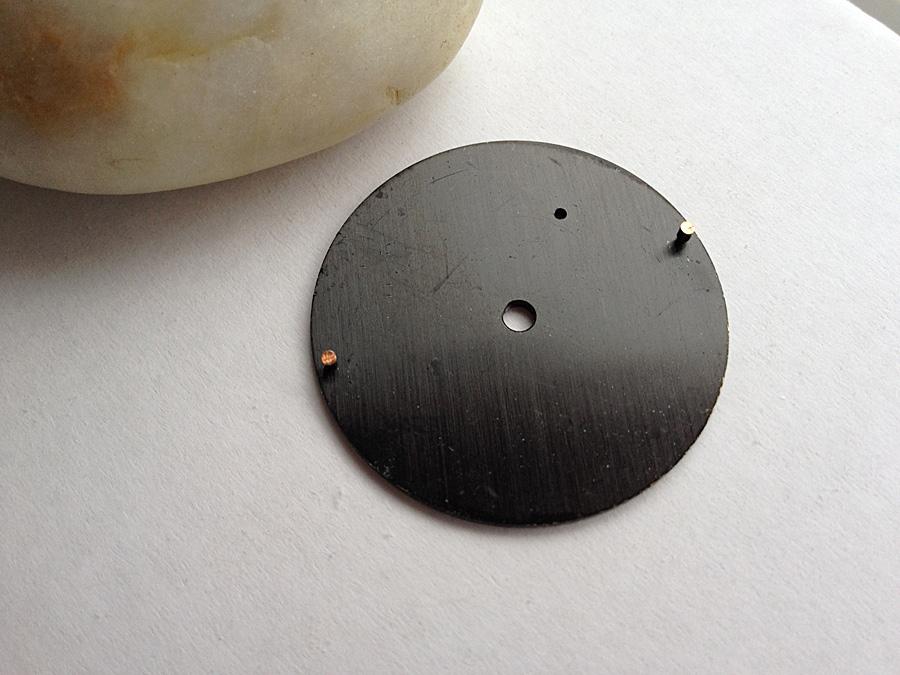

Specifications:

Rolli's FGD - 001 PreA Marina Dial Artwork in Swiss Oem Quality:

here we introduce a more than rare artwork 001 PreA Marina dial in swiss oem quality and standard.

made by a high grade oem swiss dial maker, made in switzerland.

the oem standard and oem rules say, only to use high end materials and high grade machines, made in switzerland.

materials only from swiss companies which also are developer for the well know products for the watch making, also the machines, cnc machines from almac swiss,

absolutely fast runner with 5 independent spindles and perfect for recessed indices milling and for all dial applications, also for movement parts etc.

all watch brands with in house production factory work with this special swiss almac cnc machine.

all our dials were made on this machine.

all the swiss oem dial maker have an expensive high grade machine park and be guided by ingineure.

basic material is finest brass alloy , punched to a round plate with 1,0 mm and welded the unitas 6497 feet.

indices cnc machine milled, processed the surface to a thickness of 0,97 mm.

and then on the surface the fine glass beads blasting, after the cleaning process and the black galvanic process.

for the final finish was applied the zapon varnish with satin sheen finsih.

now the dials have a final thickness of 1,0 mm.

note: all indices numerals shape have the typical pre vendome features, see the lower sharp corner

in the contour on the 6, and the preV typical numerals shapes.

PreV Style indices milling: all indices numerals contours were pre-milled with a 0.1 mm milling cutter,

so that the sharp corners in 6 could be made, after with a 0,4 mm milling cutter were milled the inner rest.

it was only possible with a special swiss almac cnc machine, and necessary a special pre working and programming on the cad program.

a very elaborate cnc machine procedure.

note: all PreV and all preA dials have this special numerals feature on the shape contours.

now the dials went to swiss rc tritec for our special tritium look.

last year we developed a tritium simulated high grade super luminova color, 10 years burned out look.

rc tritec switzerland analyzed this color and produced it in triple high grade-A super luminova a special color for us.

i could buy the original old stock tritium resin varnish UV820 from rc tritec, which was still in stock from 1993 and i could buy the rest stock.

the tritium high glossy resin varnish uv820 is the original which was used for all tritium mixes , and as protection against the radioactivity.

all indices are filled with this mixture by swiss rctritec employee by hand with the stylograph in the typical

recessed preV style filling.

the preV fgd hands are special made for us including the small second hand including a longer second hand tube,

are also filled by rc tritec with a non matched high grade-A tritium simulated super luminova.

after this process the dials went to the swiss printer, for the print steel cliché, and for the final lettering print,

also with swiss berlac paint in high glossy peal white.

this was a small introduction to the oem manufacture, i already studied for years all these single procedures and steps

and could train and instruct the dial maker for the important details,

also i trained the engineer and graphic designer for the vector graphic on auto cad for all the important sensible details. we had a genuine dial and high resolution scan all the time as basic for the profuction.

For more Details please send a PM

regards

Rolli

-

1

1

-

-

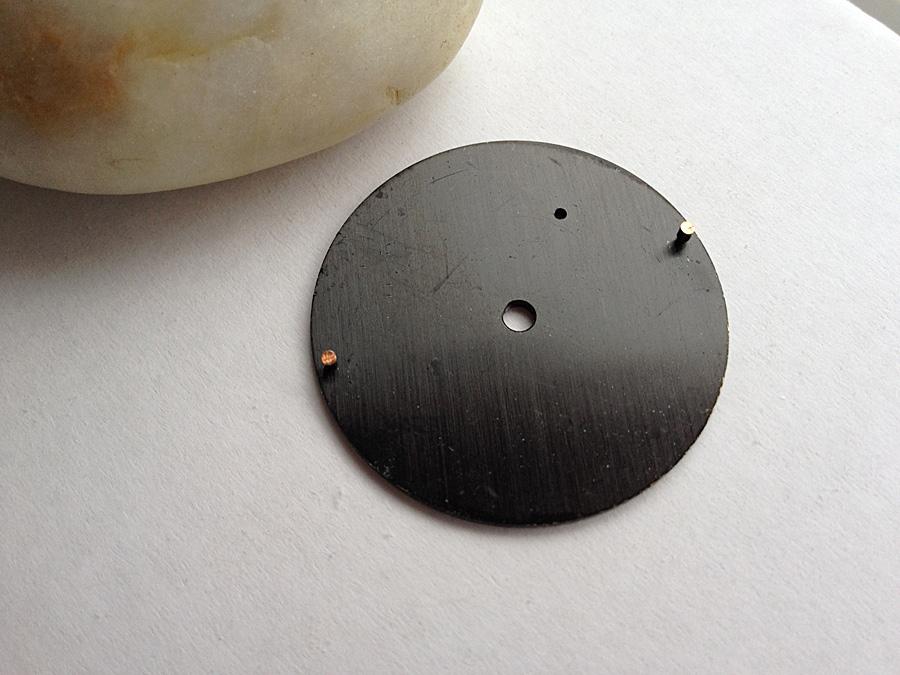

Specifications:

Rolli's FGD - 004 PreA Marina Dial Artwork in Swiss Oem Quality:

here we introduce a more than rare artwork 004 PreA Marina dial in swiss oem quality and standard.

made by a high grade oem swiss dial maker, made in switzerland.

the oem standard and oem rules say, only to use high end materials and high grade machines, made in switzerland.

materials only from swiss companies which also are developer for the well know products for the watch making, also the machines, cnc machines from almac swiss,

absolutely fast runner with 5 independent spindles and perfect for recessed indices milling and for all dial applications, also for movement parts etc.

all watch brands with in house production factory work with this special swiss almac cnc machine.

all our dials were made on this machine.

all the swiss oem dial maker have an expensive high grade machine park and be guided by ingineure.

basic material is finest brass alloy , punched to a round plate with 1,0 mm and welded the unitas 6497 feet.

indices cnc machine milled, processed the surface to a thickness of 0,97 mm.

and then on the surface the fine glass beads blasting, after the cleaning process and the black galvanic process.

for the final finish was applied the zapon varnish with satin sheen finsih.

now the dials have a final thickness of 1,0 mm.

note: all indices numerals shape have the typical pre vendome features, see the lower sharp corner

in the contour on the 6, and the preV typical numerals shapes.

PreV Style indices milling: all indices numerals contours were pre-milled with a 0.1 mm milling cutter,

so that the sharp corners in 6 could be made, after with a 0,4 mm milling cutter were milled the inner rest.

it was only possible with a special swiss almac cnc machine, and necessary a special pre working and programming on the cad program.

a very elaborate cnc machine procedure.

note: all PreV and all preA dials have this special numerals feature on the shape contours.

now the dials went to swiss rc tritec for our special tritium look.

last year we developed a tritium simulated high grade super luminova color, 10 years burned out look.

rc tritec switzerland analyzed this color and produced it in triple high grade-A super luminova a special color for us.

i could buy the original old stock tritium resin varnish UV820 from rc tritec, which was still in stock from 1993 and i could buy the rest stock.

the tritium high glossy resin varnish uv820 is the original which was used for all tritium mixes , and as protection against the radioactivity.

all indices are filled with this mixture by swiss rctritec employee by hand with the stylograph in the typical

recessed preV style filling.

the preV fgd hands are special made for us including the small second hand including a longer second hand tube,

are also filled by rc tritec with a non matched high grade-A tritium simulated super luminova.

after this process the dials went to the swiss printer, for the print steel cliché, and for the final lettering print,

also with swiss berlac paint in high glossy peal white.

this was a small introduction to the oem manufacture, i already studied for years all these single procedures and steps

and could train and instruct the dial maker for the important details,

also i trained the engineer and graphic designer for the vector graphic on auto cad for all the important sensible details. we had a genuine dial and high resolution scan all the time as basic for the profuction.

For more details please send a PM

regards

Rolli

-

again available

regards

rolli

-

205, 218, preA 001-004 will come next week

regards

rolli

-

-

-

-

-

woooooow!!!!

002- lovely!!!

right

R

-

dials are still available

regards

rolli

-

compliment

a really amazing top notch result

regards

rolli

-

1

1

-

-

-

-

-

Rolli's FGD - 055 Rare Dial Artwork in Swiss Oem Quality and Standard:

hello everybody,

and again we want to introduce another rare dial artwork the 055 in swiss oem quality and standard.

dial was made in switzerland.

the 055 with tabacco color, a real artwork made by a high grade oem swiss dial maker.

the oem standard and oem rules say, only to use high end materials and high grade machines, all these facts must be in swiss quality.

materials only from swiss companies which also are developer for the well know products for the watch making, also the machines, cnc machines from almac swiss,

absolutely fast runner with 5 independent spindles and perfect for recessed indices milling and for all dial applications, also for movement parts etc.

all watch brands with in house production factory work with this special swiss almac cnc machine.

all our dials were made on this machine.

all the swiss oem dial maker have an expensive high grade machine park and be guided by ingineure.

basic material is finest brass alloy , punched to a round plate with 1,0 mm and welded the unitas 6497-1 feet.

indices cnc machine milled, processed the surface to a thickness of 0,97 mm and the indices-edges were rounded polished, to get the coinage stamp effect.

and then on the surface the fine glass beads blusting, and after the cleaning procedure the galvanic silver coating.

since one and a half years I got the original 055 color, berlac AG switzerland is the producer and developer of top high grade-A world wide best paint. so i got the original development of the original 055 pantone color, and they developed the best paint quality.

this paint mixed with thinner for a perfect spay effect was applied in matt made by the oem swiss dial maker.

after a drying time in a 150 degrees celsius oven, next days was applied the fianal zapon varnish with satin sheen finsih.

now the dials have a final thickness of 1,0 mm.

now the dials could go to swiss rc tritec for indices fillings with the C3 triple power Grade-A super Luminova.

all indices are filled with this high grade_A luminosity by swiss rctritec employee by hand with the stylograph .

the standard shape hands are also filled by rc tritec with C3 triple Power high grade-A super luminova.

Note: from the hands, the old paint and lume material were completely removed by my swiss oem dial maker , then they got a new special oem berlac textured matt black paint burnt-in, same like all oem black pam hands.

my dial maker has a special paint spraying equipment for hands.

after this process the dials went to the swiss printer, for the printing steel cliché, and for the final lettering print,

also with swiss berlac paint in high glossy peal white.

this was a small introduction to the oem manufacture, i already studied for years all these single procedures and steps

and could train and instruct the dial maker for the important details,

also i trained the engineer and graphic designer for the vector graphic on auto cad for all the important sensible details. we had a genuine dial and high resolution scan all the time as basic for the profuction.

now you see the result, it's a real artwork.

enjoy the attached pictures.

NOTE: send a PM for details !!!!!!!!!!!!

regards

Rolli

-

1

1

-

-

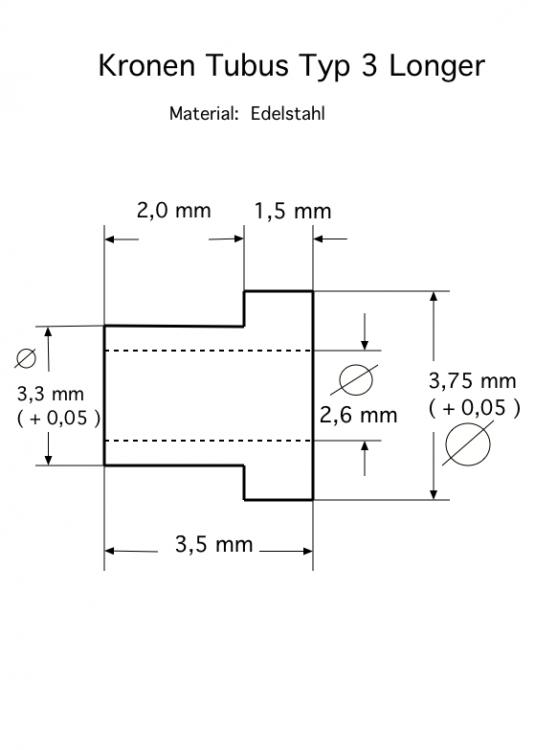

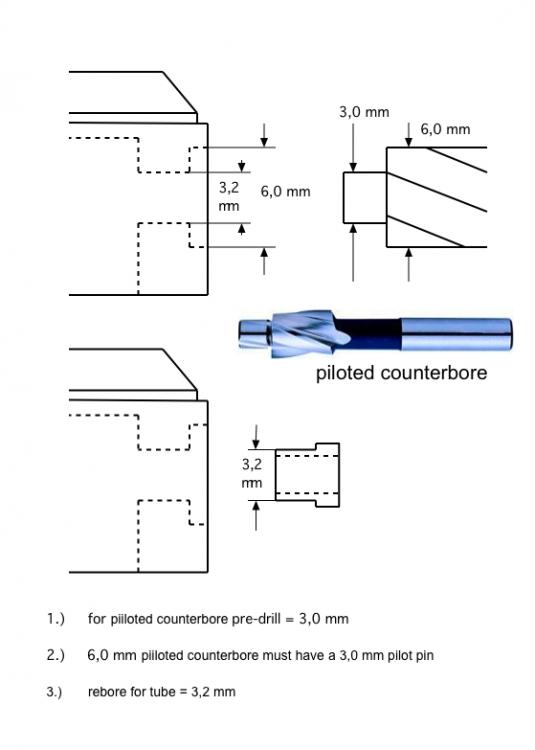

this is a special tube special made for me.

it has a longer front part, longer than from davidsen the tubes.

after pressed in the case

the inner tube measure must be fine enlarged with a reamer and control it with the davidsen oem crown ) crown with double o-ring on the neck.

after that you have to grind down the tube front part with a corundum rubber wheel, check it with the crown and CG-lever pressure.

all the best

rolli

-

1

1

-

-

Funny, I have the same issue with my 089. CG fit to the case is very gappy. I have removed the CG and strategically filed down the bottoms of the feet which has reduced the gaps but now there only just barely enough room to pull the crown all the way out when setting the time. Still works but jut barely.

to grind down the crown-guard feets is the most worst way to do this modification.

new longer tube and to grind down the tube front part till the crown and lever gives the perfect lock pressure snap.

regards

rolli

-

Thank you very much guys for your very knowledgable insights and help. I will go do some homework from here.

Rolli, when you say a new tube is needed, I assume that the space between crown guard and crown is smaller for the set up?

Thank you.

Message crafted while wrestling a juvenile crocodile that's unwilling to be captured and made into leather

davidsen case tubes are too short , his crown-guard lever too long , that's why he snded down the lever and the lock pressure is wrong,

because the lever shoves and has no lock pressure snap.

it is amateur work.

a new longer case tube,. and to enlarge the round recess with a driller or miller, adjust the oem davidsen ti crown with double o-ring

on the crown-neck with the tube and lever, and polish down a little bit till the tibe front till the vrown and lever gives a perfect lock pressure with snap effect.

don't grind down the lever !!!!!!!

all the best

rolli

-

sead1999 reachable over Repgeek - write PM

sead on rwg = Supermirrors - write PM

email adress: topproductsinc@yahoo.com

sead titanium crown-guard is a A-F serie CG,

fits perfect,

maybe new case tube would be necessary.

i alos have this CG on my 057 case from davidsen.

regards

rolli

-

dial still available

rolli

-

-

still availabe

rolli

-

1

1

-

to All a Happy new Year 2016

in The Panerai Area

Posted

hi everybody

to all a happy new year 2016 and all the best and health and that the pam passion gives you furthermore a lot of joy.

rolli