When you buy through links on our site, we may earn an affiliate commission.

-

Posts

551 -

Joined

-

Last visited

-

Days Won

4

Everything posted by RickFlorida

-

NTD Trading - Bermuda Triangle in California?

RickFlorida replied to RickFlorida's topic in The Rolex Area

Yes. The watchcases from MQ and Rubywatch look identical to the 5513 cases from NTD Trading's website so we have long believe it's the same source or family. I have a new theory by the way. I wonder if Natalie use to import them once someone ordered them but then new laws or something spooked her into not wanting to import anymore. In other words, Natalie never made the items here in the States. She would just import them from Vietnam so it kind of makes it pointless for us and more risk for her. To answer your question about Phong or his son. To my understanding they do get in trouble and that's why they change or lose websites lately and they are not responding to emails. -

Thanks. I'm not trying to be cheap or lazy. My plan is still to have a guy 3D scan and reverse engineer my case but I feel like if I don't write down what the thread profiles are, they will get it different or wrong. So having all the data I can before hand will help verify. Supposedly, the 3D scanning that some people can do on Fiverr.com is up to .05mm accuracy. I asked one of them which scanner they would use and it checked out. But they would still have to reverse engineer it and put in the CNC software what size and profile the threads are so I'm kind of worried that if I don't know all the original thread profiles, it will be slightly different when reverse engineered. I guess if the scanner is accurate to .05mm it will be okay but I figured why not ask people before hand. I thought I was all done when I got the gold nugget of information that the case back threads are 31mm by .5 pitch by 60 degree profile. Then I realized there are even stranger threads when you get to where the movement sits!

-

NTD Trading - Bermuda Triangle in California?

RickFlorida replied to RickFlorida's topic in The Rolex Area

Thanks guys, I forgot to mention that I too called Natalie a while back and left a voice mail. I wonder why she risks so much by leaving the website? To be in USA and have a website with replica Rolex parts and not even making a dollar during the risk? This lady has balls of steel. I like this Natalie woman. I would not screw with her ! She must be some kind of bad ass. -

Does anyone know the story with NDT Trading which is based in California? They would be the perfect source for rolex parts. Their website is fully operational (or at least still being paid for to be hosted) but all my research indicates they have not sold anything is over 4 years. Maybe even 6 or 8 years. They don't respond to inquiries but the website would be a good source of parts. Especially for those in the USA who hate wiring money to Vietnam. Why would you leave a website on for years that exposes you to Rolex replica parts while based in the USA if you have no intention of selling anymore? So is there a referral we need to be able to purchase from them? Did this person fall prey to a California mountain lion but left the website host on auto pay and it went through for 8 years?

-

Thanks. All I want to ask him is how did he or his case maker figure out the threading that start where the movement screw sits (the half moon shaped cut out). The threads from there to where the dial sits. I figured out the caseback threads but it then steps down to a smaller diameter. It's really hard to figure out how these threads were made. Maybe he has drawings? By the way, the picture is just from the internet for quick reference, it's not mine. Maybe he can give the contact information to the company that made his cases? Whatever is easiest or comfortable with him.

-

The case doesn't even have the half-moon shaped cut out for the movement screws. But the crown guards are not real bad. I wonder if the case was a Helenarou that was worked and then engraved?

-

-

I like Helenarou dials for their price and their fit for ETA movements. The triangle at 12 O-clock on Yuki's is way way too short. I didn't notice this until someone showed me the Helenarou or other dials. I can't believe how short the triangle is on a Yuki dial compared to gen. But there is no perfect ETA fitting rolex dial you have to just go with what you decide. The lume color is really really wrong on them but I love everything else about the Helenarou 5513 dial. It may have other flaws that are beyond my knowledge but it works if you are just trying to fit to ETA. I wondered this too but I strongly believe that it's due to volume and interest. The large wholesalers are filling a larger demand for replicas of newer rolexes so they get more updates and quality. The market for accurate vintage replicas is a tiny portion of the market for newer rolex. At least this is what I think is the reason we won't get perfect cases from them. The scary thing is that one by one the vintage replica case makers are disappearing. NTD Trading in California stopped selling over 4 years ago (but her website is still up so I wonder why she is paying for it. Phong does not answer any emails, at least to me. And his son's website is completely gone. So that leaves us only with Rubywatch and MQ in Vietnam for good cases. That is why I'm desperately trying to reverse engineer a 5513 case for CNC file uploading in case we never have a source.

-

Thanks again everyone, especially Automatico. So I have a new question I need to work on before I try to get a CNC file made. One thing I didn't realize is that the rolex screws slip under the first radius (that the half-moon cut out shape for the screws). So the threads that seem to go all the way down inside the midcase even after this half-moon shape radius are more important than I thought. I assume the threads are there due to how the half-moon shape radius is created. The diameter of these threads (if that's what they are) is smaller than the diameter of the caseback. So now I think I have to discover what these threads are dimension-wise. I only have an MQ case but it does have the half-moon shape and fits 15xx so I should be okay if the reverse engineering is done on this. Does anyone have any other knowledge of these inner threads from the half moon shape to where the dial sits?

-

I have seen other people claim this but Automatico always has the best information. On another forum, a guy claimed "1530 is the base caliber for many movements, it is actually 28,5mm x 6,30mm whereas the 1520 is 28,5mm x 5,75mm" but maybe the 1530 had a date function or something?

-

Thanks for the replies everyone, this has been very helpful to hear what you all think and about the fellow who tried to get China to make cases for him. I respect what he tried with the 5514. I only want to try to make the midcase and maybe the caseback plus I want to eliminate the need to depend on those factories overseas. I'll keep posting any updates but I don't think real progress would be until summer. The purpose of this post is really just to share my idea. By the way, does anyone know the exact dimensions of a 15XX no date movement with the dial? Or what is the thickness of a dial and the thickness of the 15XX movement and I can just combine them? It's awkward measuring the inside of the case so having the exact dimensions of a 15XX movement with the dial will help me a lot. I know dials are 26mm in diameter but not sure of their thickness.

-

I'll do my best. A few things will have to happen for this to be a real project. I will have to get enough funds to pay someone who can create the final CNC file for 5 axis machines. And.... I'll have to figure out how to create the closes shape to acceptable crown guards before I send my Vietnam 5513 case. My Vietnam 5513 Case is the closest thing I have to genuine but it has the 1990 thick looking crown guards. Most people want the 1960's looking crown guards. So before I would send my midcase to the guy to take accurate measurements, I would want to fix the crown guards or everyone will be bitching. LOL (The picture I used above is from the internet to just show a quick description of my question)

-

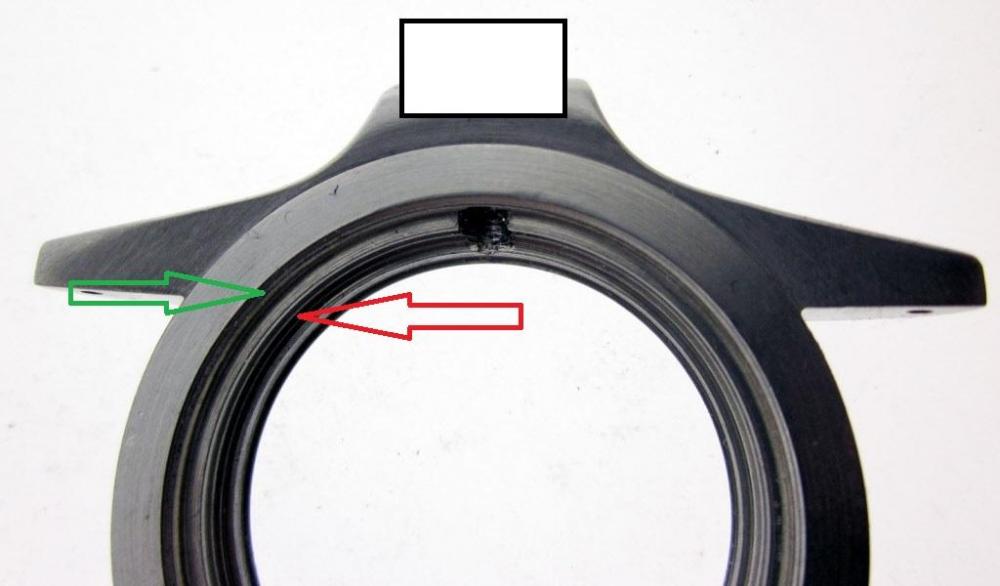

Hello. In my quest to see if a CNC file of the 5513 case can be made and then it would simply be a matter of sending the file to an online 5 Axis CNC service like 3d Hubs, I was wondering if anyone knows the purpose of the multiple dimensions you see on the inside of the case radius. The Green Arrow is obvious. These threads are for the caseback to screw into. Thanks to an Italian watch maker who does repairs, he shared with me that the thread size of the 5513 (and I assume 1680) is 31mm diameter, .5 pitch and the standard 60 degree thread profile. But why do we see multiple threads/surfaces in the red area? I'm assuming that the reason for these other thread looking parts is that in order to to create the nesting surface for the 15XX movement (the perimeter you see that has the half moon cut out to slide the movement holding screws into) they had to continue using a die/thread cutter. In other words, all of these extra looking threads is only because they made the rolex cases on a lathe, they did not have 5 axis CNC machines. Am I correct? So if we want to just make a CNC file, we just need the movement holding space, the threads for the caseback, and of course the inner smallest diameter to hold the dial? Is my thinking correct? Thanks for any help. If I succeed in making a 5513 CNC file for the midcase and maybe even the caseback, this will help us get cheaper cases. But these would be sterile.

-

This question has been solved. Davide Biguzzi of http://www.laboratorioportanova.eu/index.php/contatti/ kindly shared with me the following answer. The Rolex 5513 (and I assume the 1680 and Tudor 7928) had the following thread size for the midcase. (This should be the "tap" size if you had one made to create a case from scratch on a lathe) diameter 31.00 mm and 0.5 pitch,It is a metric size with 60 degree thread profile So we have known the tap size for the crown tube for years, 3mm X .35 and now we finally know the tap size for the where the case back screws on.

-

And here the old threads are repaired on a 5513, they just make a cutting tool at 60 degrees after laser welding enough material back on the old threads. But I'm curious what the actual thread size is like if you made a tap and die. http://www.laboratorioportanova.eu/index.php/portfolio/lavori-su-casse/restauro-di-una-cassa-rolex-submariner-ref.5513/?lang=en

-

I found this information today. Any thoughts? https://forums.watchuseek.com/f6/thread-sizing-watch-backs-1289674.html Particularly this statement: "metric threads are typically sized such that the tapping size is thread designation minus the pitch. m39x0.5 would have a minor dia of 38.5mm, 60 degree thread form, 0.5mm pitch if i was making a case and back that's about where I'd start." Dave

-

That is crazy!

-

Is this for real? What is really strange though is that I've seen a TON of listings of submariners where the movement is real but the dial and the case are listed as "replacements" but don't have the right Rolex replacement serial numbers for replacements. I forget what it is but Rolex did replace some cases if they were not water tight but there is a certain two digits or letters they begin with. The sellers on Ebay just take a real movement from rolex but use a high quality aftermarket case and sell the submariner. The seller is being kind of honest saying it's a replacement case and dial but what I'm surprised is that Ebay nor Rolex end the listings. I think they all go through so you just have to word things correctly.

-

Hello everyone, The short question is what is the thread size/name for the actual caseback on 5513's (and I assume 1680 and Tudor 7928 is the same)? I see that people like Automatico have posted the size is 30.9mm but what is the pitch? The threading of the midcase for the crown tube is 3.0mm x .35 correct? The ".35" at the end of 3.0mm X .35 for the crown tube is the pitch. We need to know the pitch of the 30.9mm caseback threading in order to reproduce the case. In my quest to explore how 5513 cases might be made which must have an expired patent on........I am still brainstorming on this. I have given up on 3D printing as an option as it really would not work. If we tried 3d Printing a case, you would still need to machine it to finish the threading and apply a correct finish to the surface. This would just make it cost more than designing a CAD file and having it CNC'd because by 3d Printing, you essentially would be making the case twice. My new option is to make a CAD file either by designing it from scratch or by using a potential contact to reverse engineer a case I have. I don't know how far I can get but I will try. I'm not totally against the fact that we have to pay 1200 bucks to Phong to get a complete case that we know is great and even would ship from and stay in the USA, but a CNC file would preserve our ability to get these. I think people will stop making these and I hate that when I asked for a sterile version of a 5513 replica case, I had to pay more when I got it from Vietnam. Thank you!

-

Hello everyone, Does anyone have experience getting in touch with NDT Trading? I have called the California number on the website and left a friendly voicemail saying what I was interested in (5513 case that looks just like MQ Vietname and Rubywatch) and a Maxi Dial that I would need in a few months. I thought I would ask if they would be in stock and whether I would need gaskets for the crown as well as the caseback. I also sent an email or two over the last few weeks and never got any responses. I've read that the NDT Trading person is a lady named Natelie from other forums. Since I'm in USA, it would be far easier for me to purchase a 5513 case from NDT Trading which appears to be in San Jose California rather than me make another purchase with MQ Vietnam who quickly dispatched my last case but required expensive Western Union fees and postage issues from there. NDT Trading would be the perfect solution for people on this side of the pond but I have failed to get any responses. Does anyone know this person and would help me get in touch? Thank you, rick

-

Clutch Spring of aftermarket 702/703 crowns comparison?

RickFlorida replied to RickFlorida's topic in The Rolex Area

Thank you. I think I will just have to use a 703 tube and crown on the next build then because the Athaya clutch spring for the 702 failed very, very quickly after the build so I can't see using these again. -

Clutch Spring of aftermarket 702/703 crowns comparison?

RickFlorida posted a topic in The Rolex Area

Hi everyone, So I realized recently that the clutch spring of my Athaya 702 failed very quickly. I love the crown but it has to function for me. Since I will soon be in the market for a complete MQ or Rubywatch 5513 case I wanted to ask if anyone knows if the crowns that come with those cases have a better clutch spring than the Athaya 702? My current 5513 build has a MQ midcase but I purchased the midcase only from MQ so I never tried one of their crowns. While on the subject of those complete 5513 cases, do they come with all gaskets for crown? By the way, is a clutch spring inside the crown something that can be replaced with a new or genuine part or are the clutch springs permanently pressed in? Thanks for any information. -

Question about a tube for 5513 case. Help request.

RickFlorida replied to azbank's topic in The Rolex Area

I finally realized this is what happened to my 5513 project! I thought my keyless works were screwed but then I realized that if could play with the crown and finally still set the time. I can't believe how fast the clutch spring failed on the Athaya 702. I only had the watch a short time when this happened and I rarely set the time. I keep my watch water proof by testing and then not changing time unless I have no choice. I set my ETA based 5513 build crown "up" to slow it down at night so I don't have to change time much. When the time changed last year, I went to change the time and the clutch spring was already failed. I think mine failed instantly! -

Startime's source for the 3135 replacement case?

RickFlorida replied to RickFlorida's topic in The Rolex Area

Agreed. when I first got the MQ 5513 Case I noticed right away that bezels and retaining rings fit perfectly flat on them unlike the the cartel. Plus, When I fit crystals on the Cartel, they would usually crack after some time. I think they are not perfectly round (the case necks). I put a very tight crystal on my MQ 5513 case and it has not cracked at all. The son of a [censored] is water proof as heck as I use it in the saltwater. I love the MQ cases and I assume RubyWatch are the same. Plus I think Phong uses the same case but just shapes it more by hand? Who is making all these cases originally? -

Where to buy a Cartel 1680 / 5513 Caseback

RickFlorida replied to GSmaniac's topic in The Rolex Area

Just some info. I learned after working with Cartel cases. Even when properly shaped, I found the Cartel case very difficult to make into a good finished product. For example, once I got an MQ vietname case, I realized how nice and flat bezels can sit on it. The Cartel case was not truly flat where the bezel and crystal sit. Plus, if you ever want to purchase and use real rolex movement, buying an MQ, Rubys, or Phong case, Yuki case will pay dividends as you can just drop a 15xx in there. For only 500 bucks, I got MQ to send me a sterile Midcase. It's worth it.