-

Posts

100 -

Joined

-

Last visited

Everything posted by Ado213

-

Hi KBh, you don't need a taller canon pinion set in the movement, got one here with H3 handstack and it's fine, had to take the H5 off that I had fitted it was just too high

-

Food for thought, if you could get the Dial with eta date window rather than the Rollie would this not be a easier fix?. No DWO and you could use the stock H3 pinions? Yes this would put the movement out of alignment with the crown tube, but that's an easy fix !

-

I see, one of the spot welds broke on the bracelet links of the clasp. The TD just sent you 1/2 the clasp, that's not good all you can do is file the rivet head off and push the pin through. But then you have a problem as the pin will not be long enough to create a new rivet head. So you will need a new pin, hammer and doming tool, not an easy job unfortunately. Better idea is take your existing broken bracelet into your local jewellers and ask them to "silver solder" the broken link back on the clasp. This is an easy job for a working goldsmith, if done correctly this is a stronger joint than the spot weld previously applied, it will not break again. There will be some discolouration to the clasp, but again the jeweller can easily polish this out. Estimated cost on this £20-25 a far quicker and effective repair than trying to do it yourself

-

I hear you want to remove the pins, but what is the problem before we go down this route?

-

You will find the DWO fits better on a 2836-2 than the 2824-2, there is just that little bit more clearance between the date corrector and the top of the date wheel. Also 2836-2 come standard with H4 pinions, so no extra cost for changing the 2824-2 pinions if you need to.

-

Rolex Seadweller 16600: Advice considering crystal needed

Ado213 replied to Ticktick's topic in The Rolex Area

The ST xtal will fit the BP SD, but you will need to custom make a gasket, the BP gasket is too small. I'll post pics and your drawing Andy, as soon as I get a minute mate! -

Rolex Seadweller 16600: Advice considering crystal needed

Ado213 replied to Ticktick's topic in The Rolex Area

Andi, I have a drawing of the dimensions I bored out the BP SD to, it may help you if you get chance to attempt it?. If you can hang on until I get back from hols, I am re boring the prototype so the crystal sits lower and I can get rid of the remaining existing rehaut. Hopefully then all will be well to copy! -

Rolex Seadweller 16600: Advice considering crystal needed

Ado213 replied to Ticktick's topic in The Rolex Area

Hi Andi, thanks for the link (very informative post) yes do know the DSSD has xtal to steel, perhaps I am confusing myself with mu limited knowledge of glass/crystals. I do now that toughened glass should never touch steel as it almost always cracks and shatters, but here were dealing with a different animal "sapphire crystal" completely different composition and properties. I think I'll have to do a lot more reading up on sapphire crystals to understand their mechanical properties. But that apart, and after your excellent dimensional work on the gen SD, i feel I have enough to progress to see if it is possible to get the look and water tightness we would desire. Only problem now is time !!. On holiday from the 5th-May for a fortnight, so this going to slow me down just when I have everything to progress !! -

Rolex Seadweller 16600: Advice considering crystal needed

Ado213 replied to Ticktick's topic in The Rolex Area

Hi Andi, I did as you say, assembled the gasket xtal and rehaut before pressing into the case. I just don't get this seal !! It seems so little of the xtal is held within the case. Plus there is no seal between the xtal and rehaut. If you look at the sub or Deepsea there is a seal seat that the xtal "sits on" No such thing here, the xtal sits on the rehaut. Anyway, with your dimensions, I can probably track this and see what's going on. Let's get this cracked, seems we can't get an alternative at the moment. Plus looking at the oics, the BP xtal sits higher than gen. -

I know it's an old post but, impressively correct. Had me fooled for a long time !!

-

Rolex Seadweller 16600: Advice considering crystal needed

Ado213 replied to Ticktick's topic in The Rolex Area

Cheers Tictick, this will do very nicely. Just what the doctor ordered!! At least now I have the gen measurements, which should allow me to reveres engineer the BP Thanks a lot, I can see you've put a lot if time into this, perhaps now we can collectively crack this!. -

Rolex Seadweller 16600: Advice considering crystal needed

Ado213 replied to Ticktick's topic in The Rolex Area

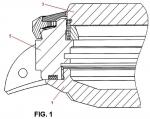

Ok as soon as I get the measurements, I'll see what can be done. Now I have seen the gen crystal height it will make my job that bit easier, dimensions will be a massive bonus. One thing I have noticed is that on the gen ( See cross sectional drawing, posted earlier) the crystal sits directly on top of the rehaut!. Very strange, to have glass touching steel, not really good engineering practice. There looks like a small "bulge" in the gasket at the contact point of the xtal and rehaut, perhaps this is created when the xtal is pressed in, it certainly wouldn't be machineable in the gasket?. But then again the rehaut, xtal and gasket would have to be pressed in together (what I did) as I don't see a way of pressing the xtal in post rehaut without damaging the gasket?. Any ideas anyone -

Rolex Seadweller 16600: Advice considering crystal needed

Ado213 replied to Ticktick's topic in The Rolex Area

Cheers Andi, very much appreciated, it's the missing link! -

Rolex Seadweller 16600: Advice considering crystal needed

Ado213 replied to Ticktick's topic in The Rolex Area

Hi all, finally found some time to contribute to this interesting post. So first we look at a generic replacement xtal and gasket for the SD. This is not a gen xtal and gasket, but from what I have learned it should fit a gen SD?. You will notice the gasket is much deeper than the xtal,itself, reviewing the sectional drawing of the gen SD case I posted earlier, this is correct?. So the problem is now, how to get the xtal in the case?. Well the only way is to machine the existing rehaut out. Not having a gen SD to measure is a pain, so all I can go off is the height of the BP SD as it arrived with me. This was a mistake, after looking at the great pics posted of the gen, I could have gone deeper and sat the xtal that bit lower. So out come the existing rehaut, and i make another using the same rehaut angle as the BP. Again with not having the gen it's all I can go off, here's a pic of the rehaut So we now have the three piece construction of the front end, Xtal, rehaut and gasket. On machining the existing rehaut out of the case and to retain the BP xtal height you are left with 0.020" of the existing BP rehaut left in the case, this is a visual problem, you can actually see the joint between the new rehaut and the remainder of the existing. This is why I said I made a mistake, dropping the crystal height would have allowed me to take all the existing BP rehaut out and replace it with a slightly thicker new rehaut and therefore removing the unsightly joint between existing and new. Here's a picture of the case with the new xtal, gasket and rehaut in from the top, I've tried to show the joint but it is hard to spot, but it's really not good enough to me!. And here's a shot from the side, which shows the xtal at the same height as the stock BP So in short this is a doable exercise, all I need is the gen measurements off an SD front end to do it correctly. -

Rolex Seadweller 16600: Advice considering crystal needed

Ado213 replied to Ticktick's topic in The Rolex Area

Wow, I've never seen them side to side so to speak, big difference. The BP crystal is higher, which is good for me ( reasons on the way) and the bezel angles are completely different . This makes a big difference to machining the case out to accept gen xtal. I knew the gen bezel insert was flatter (seen picture of this before) but not in as great a detail. Thanks guys, keep it coming, going to have to find the time to post my pics of the xtal, this is getting interesting !, -

Rolex Seadweller 16600: Advice considering crystal needed

Ado213 replied to Ticktick's topic in The Rolex Area

Thanks so much for posting the extra pics, which have captured the elusive bevel. I'll post some BP shots for comparison -

Rolex Seadweller 16600: Advice considering crystal needed

Ado213 replied to Ticktick's topic in The Rolex Area

Great pic, let's have more !!, -

Rolex Seadweller 16600: Advice considering crystal needed

Ado213 replied to Ticktick's topic in The Rolex Area

Great idea, there are generic crystals available, but the do require the case to be modded to use both the crystal and gasket. As in the drawing posted. I am no expert on the exact crystal chamfers (bevels), and dimensions of these would be a great advantage. Too many times have I heard that the height "looks" wrong, the crystal chamfering "looks" wrong. IMO These are all subjective views and without the correct dimensions cannot be justified. Does anyone have a gen xtal they could measure accurately and publish their findings I'll go with Ephry on this one, let's do a bulk buy, put me down for 5 PS. Post coming on case machining -

Rolex Seadweller 16600: Advice considering crystal needed

Ado213 replied to Ticktick's topic in The Rolex Area

Glue it !! -

Rolex Seadweller 16600: Advice considering crystal needed

Ado213 replied to Ticktick's topic in The Rolex Area

Yes, I will post pics of the mod, funnily enough I still have my first attempt here. -

Rolex Seadweller 16600: Advice considering crystal needed

Ado213 replied to Ticktick's topic in The Rolex Area

Yes it does with mods ! -

Rolex Seadweller 16600: Advice considering crystal needed

Ado213 replied to Ticktick's topic in The Rolex Area

Oh do you?, that's strange never publicly declared I had done it ? -

Rolex Seadweller 16600: Advice considering crystal needed

Ado213 replied to Ticktick's topic in The Rolex Area

Anybody wanting the case machined to accept gen xtal can contact me, if they need help. -

Rolex Seadweller 16600: Advice considering crystal needed

Ado213 replied to Ticktick's topic in The Rolex Area

The TC and Clark crystals will not fit if your modding the case to take gen, gen crystal is 3mm thick. The 16600 has a three part xtal assembly, the rehaut being removeable?. Correct me if I'm wrong not handled a gen Picture courtesy of Sconhead -

First port of call is Andrew, give him the chance to rectify the problem. If this is a now go, get yourself a 2893-2 and drop that in, it's a bit extreme but it's the best GMT movement out there !.