-

Posts

303 -

Joined

-

Last visited

-

Days Won

7

Posts posted by manodeoro

-

-

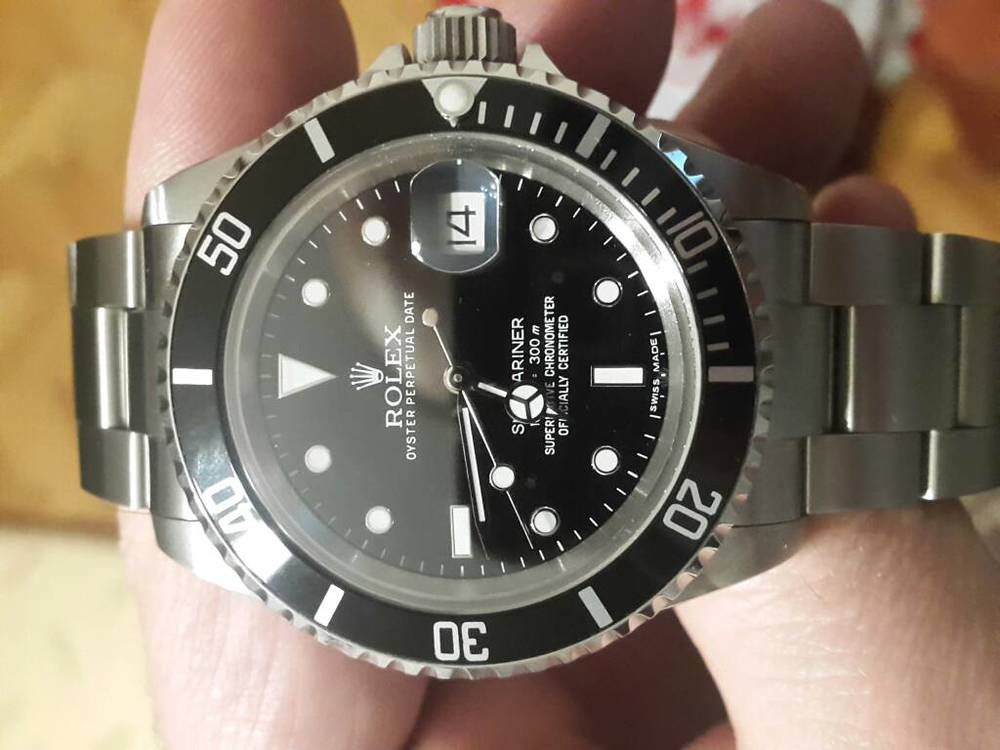

I got from Tony @ RWI

Sent from my SM-G850F using Tapatalk

May I hask you how much you paid for that 16610 ?

Envoyé de mon XT1068 en utilisant Tapatalk

-

Ya I know it's not well known. But Noob, jf, bk... and the rest are not having 16610 any more. They focus on the newer modela 116610. That what i found so far...

Sent from my SM-G850F using Tapatalk

Its cons. That LE don't accept gen parts (as far as i know till now)

Sent from my SM-G850F using Tapatalk

BP has a 16610 (I bought one a few months ago) and JF has a new 16610LV and will soon sell a 16610LN.

From which seller did you bought your LE 26610 ?

Envoyé de mon XT1068 en utilisant Tapatalk

-

Never heard of LE Factory.

Noob, BP, JF ... but never LE

Envoyé de mon XT1068 en utilisant Tapatalk -

Definitely a "strange" early 16610 but whit some DIY mods it could be a nice daily beater.

Is your bracelet a 93250 ?

If YES you could drill the lugs and SELs so that they accept 2mm bars ... you can do that with a 1mm diamond file.

But the first thing I would do, if I where you, is to check if the bezel can be easily removed.

If YES you can easily rework the case and crownguards.

Envoyé de mon XT1068 en utilisant Tapatalk -

It is "something else"

But, as I wrote in your thread, I'd really like to see better pics.

Envoyé de mon XT1068 en utilisant TapatalkHi all i buy this le factory whit sa3135 movement but i don't like the crystal...i can't change whit a gen one because the case don't accept it...what i can do? Thanks

Inviato dal mio iPhone utilizzando Tapatalk

"le factory" ?

What is your crystal size ?

Envoyé de mon XT1068 en utilisant Tapatalk

-

-

Strange watch ... some sort of mixed up :

- drilled lugs like an early 16610

- 93250 SELs bracelet late 16610

- stubby crown guards and maxi dial like a late 116610

Would you post some better pics of the dial and case ?

Envoyé de mon XT1068 en utilisant Tapatalk -

Nicely done ... though "butchered" is almost an euphemism there.

I'll add just one comment :

"Next time you dive 2000ft down you'd better keep your watch INSIDE the u-boat"

Envoyé de mon XT1068 en utilisant Tapatalk -

Sorry didn't mean to insult if you took it that way when i assumed you were Norwegian Just assumed so as its quite hard to get into that sector of offshore. Its a great spot to be as im sure you know this from your son. The money is good but the schedule is the best you can get offshore. International Contracts are much higher paying, but you also dont get the same treatment as you would in the Norwegian sector. Ive been wanting to for years, but you would have to know Norwegian and mine isn't that great even after living there for a while. I was there with National Oilwell Varco, Aker's rival lol

Just assumed so as its quite hard to get into that sector of offshore. Its a great spot to be as im sure you know this from your son. The money is good but the schedule is the best you can get offshore. International Contracts are much higher paying, but you also dont get the same treatment as you would in the Norwegian sector. Ive been wanting to for years, but you would have to know Norwegian and mine isn't that great even after living there for a while. I was there with National Oilwell Varco, Aker's rival lol

I almost went down the instrumentation road a while ago before i went to university. its a great field and pays well, also with the way the industry is now on a low they continue to be in demand, so a good place to be. Im sure when things pick back up your younger son will have no problem hooking a big job with an oil and gas company. Once you are in the industry you can pretty much pick what you want to do and where you want to go when the markets are up. I remember back 5 or 6 years ago, you could literally quit and have a job somewhere else the next day, i miss those days lol and the money was just insane. I had mechanics on my rigs making over a quarter of a million USD.

That dial looks great !! how did you do the comex on the dial ? screen print or transfer ? it looks really good ! looking forward to seeing the finished watch. and budget builds are nothing to look down on.. ive seen some builds that were pretty damn fine and cost very little to do. It sounds like you have a lot into this one and im sure it will be well appreciated by your son ! looking forward to seeing the photos !

Cheers !

C.

The dial is designed with Illustrator then printed on white decal paper, put on the dial plate then 5 coats of varnish.

I first tried to keep the original dial and put the COMEX and SWISS-TSo I modded the whole dial.

I will show all the process in a specific thread went RWI is really back.

Envoyé de mon XT1068 en utilisant Tapatalk

-

2 hours ago, altesporsche said:

Im a big fan of a vintage stuff as well ? I

am also in the process of building a COMEX, but the earlier 5514 version lol it's been a two year or more process because I'm anal about parts.

I will look forward to following your thread on the Comex for your son, I always loved the 16800's

you are damn close on the Subsea engineer ? And yes on the oil and gas. I worked as a tooling engineer for ROV's for a while then a subsea engineer for some years and now back into my field of fluid power working as a hydraulic engineer for the complete drilling package and subsea systems. I get to get my hands dirty a little more and it keeps the mind fresh lol

You must be Norwegian ? Or your son won the lottery lol as Norway is the dreamland for offshore workers. Everyone wants to work there but it's nearly impossible.

Id go there in a second even with a hefty pay cut lol but a lot of it is because I love the country and would use it as an excuse to move there.

Cheers and thanks for reading !

I'll be looking out for that project.

My 16800 build is a low budget (I'm not Norwegian and I dont work in oil & gas

) so I'm trying not to be anal about details.

) so I'm trying not to be anal about details.

I just bought a BP 16610 Sub and mod it myself to a "year 1984" 16800 COMEX :

1 - mod the dial to a COMEX one (remove the indexes, DIY decal, put the indexes back ... it turned to be an easy mod)

2 - drill the lugs for 2mm bars (most difficult part of the job ... almost ruined the case)

3 - drill a 93150 bracelet and 380 endlinks to accept 2mm bars

4 - rework the lugs to a thinner profile and redo the chamfers (work in progress)

5 - remove the engravings on the rehaut (just kept the serial number)

5 - engrave the caseback (diver's number will be 193 ... my son's size in centimeters)

6 - build a vintage service box

I'll add a vintage leather strap from cheapnatostraps (I already made some myself but I'm short in time so I jsut bought one) with a rolex buckle (brushed with a polish coronet), put everything in the DIY service box and give it to my son next sunday ... if everything goes well.

Here's a pic of the dial and one of the "service box)

I'm definitely NOT Norwegian ... just French.

My son studied instrument engineering in France (INSA) then oil & gas engineering in GB during 6 months.

He needed an internship for his 5th academic year so he sent a resume to Aker Solutions in Oslo and got a 6 months job as an engineering assistant ... and they never let him leave.

He lives there since 9 years now and since 2 years I have a Norwegian grandson

BTW ... considering what he's earning there I'm not certain you would get a huge pay cut if you get a job in Norway.

Norway and oil & gas jobs make everybody dream ...

That's why my youngster son did quite the same studies and works as an instrument & control engineer for a small consultancy company.

He's based in France so he earns much less money than his elder brother but he does a lot of consultancy missions abroad (only 26 and he's already worked in Norway, Singapore and Russia) so he really enjoys his work ... and he still hopes to get a permanent job in big oil & gas company.

-

19 hours ago, altesporsche said:

Exactly @mrsoundman ! That was my point and the whole reason I posted this.

Model paint for the most part is acrylic so you need to seal it and still it's just paint and will wear much easier than the chemical based paints used in a simple sharpie marker lol

we use the gold version of this marker for marking stainless tooling that we send several thousand feet below the seabed to drill rock.. so it's a tad more durable than acrylic paint ?

im not crapping on what this guy is doing, but yea I inquired about getting one done for a watch I'm building my brother (don't want to buy a gen insert to give away lol) and when he came back with it having to be removed (which is expected and quite easy for someone who's done it before) but for the majority of people who feel better sending it out to be removed, it becomes a pain in the ass. Then ship to Singapore, turnaround on his end is 2 weeks for his 99.99% platinum (which is impossible for this application) as there are only a few ways you can plate or coat non metal ceramics and plastics, one is electroless plating which would involve submersing in an etching bath that would ruin the polished surface as well, then you have sputtering which is the process of applying plating in a vacuum chamber and quite costly equipment (not worth it for this application) then you have electroplating which cannot be completed unless the electroless plating is performed as a means for the materials to adhere to in the plating process, then finally you have spraying which is taking a powder form of a metal and basically brazing the material (no go with Plastics) and I can't see this with ceramic due to the high melting temp of the 6 platinum group metals being between 1770deg C and 3050deg C, it's actually unlikely that even Rolex uses pure platinum as a plating on ceramic. I can see if the service included an insert and then you send your old one back etc.. but $290 is steep for "plating" as only the GMT will need the cleaning up of the edges (again visible under 10X not the eye unless really really looking for it) anyways

that's just my 2 cents worth from 10 years of experience with precious and noble metals and a Phd in mechanical engineering.

In my eyes with my gens next next to the "sharpies mod" lol it's much more worth it than giving someone almost $300 usd or more after having someone else remove it etc.. in which you are half way or more to the cost of a LN insert , just to make it look the same as spending an hour with a $8 marker that is nothing like the "old school" model paint mods..

Very great thread @altesporsche ... thank you VERY MUCH

Though I dont have any ceramic bezel (I'm stucked on vintage and "early modern" watches so only metal inserts) I really appreciate the informations you provide here.

Sharing experience is a great and very honorable behaviour.

So it seems you work in subsea engineering ... oil & gas or else ?

If YES you could be interested by the 16800 COMEX I'm building for my elder son (oil & gas instrument engineer in Norway) ... I'll create of thread about that build as soon it's finished, possibly next week.

-

1

1

-

-

-

6 hours ago, Sogeha said:

The way I look at watches like this is you can either build a franken or buy at the top end from a very reputable seller. If you do the former, you have a convincing watch you can wear, the later is a watch I doubt many would be comfortable wearing and buying anywhere else in the market is likely to be paying well over the odds for a franken anyway.

Same goes for COMEX subs

+100 ... dont even need to build a real franken

Here's a 76K$ 16800 COMEX sub ... not sure anyone would feel comfortable wearing such a watch

and here is what you can get with 16610 dial and some skills ... just put it in a modded 16610 case with drilled lugs and 93150 bracelet ... enjoy

-

1

1

-

-

Now you HAVE to post pictures !!!

Envoyé de mon XT1068 en utilisant Tapatalk -

I'm also really confused on the dial seat. It seams that it is exactly the same size as the dial. So the dial would just fall trough if I let it go. Shouldn't it be slightly smaller so the dial rests on it or is that what the movement would do?

I'm afraid so.

Didnt you checked the dial seat BEFORE selecting your dial ?

Envoyé de mon XT1068 en utilisant Tapatalk

-

Yeah hopefully you're design will come out as planned

thats my lathe in the first pic, waiting on a outside chuck so I can finish my the bezel and hopefully make it fully functional .

A lathe !!! So you're heavily equipped

I too really hope your dial come out as well as possible

With the work you're doing that A/6538 will be a very stunning and unique piece so I judt cant wait to see it finished.

Which movement are you planning to use ?

Envoyé de mon XT1068 en utilisant Tapatalk

-

OMG ... I'm definitely following your thread. Hope you'll take pictures while welding the bars.

What is the tool (machine?) on your first pic ?

Envoyé de mon XT1068 en utilisant Tapatalk -

15 hours ago, SSTEEL said:

I do plan on doing just that as well as documenting some jobs that I carry out for customers, the trouble is, finding the time to do this, as I am very very busy, I have a blog which I struggle to find time to post on, but I must make time to share more for sure.

12 minutes ago, manodeoro said:

At least could you just tell me :

1 - have you drilled lugs (non predrilled) with a Dremel ?.. YES/NO

2 - if "yes" then did it worked well ?.. YES/NO

Those YES and/or NO wont be much time consuming but very much helpfull for me cause I'm in the process of picking the "right" tools to mod my watches (now I do most of the job with files, sandpaper and my hands).

Envoyé de mon XT1068 en utilisant Tapatalk

Here is what I would buy, if it proves to be possible to drill lugs with Dremel :

- Dremel 3000 : 70$ (pic) or a "Rep" one (50$)

- 43 mm adapter for Dremel : 15$ (pic)

- 43 mm precision drillpress : 70$ (pic)

- 43 mm stand : 15$ (pic)

- drill bits and accessories : 30/80 $

So for about 180/250 $ I could get tools good enough to do all the work on my own builds (I will not mod for other members ... just my own watches).

What do you think about that ???

DREMEL

[url=http://www.hostingpics.net/viewer.php?id=589536i608935.jpg]

[/url]

[/url]

43 mm ADAPTER

[url=http://www.hostingpics.net/viewer.php?id=235120mbI9KX1oFqVCtbNZLxpAm7w.jpg]

[/url]

[/url]

PRECISION DRILLPRESS

[url=http://www.hostingpics.net/viewer.php?id=6982085027000FS15.jpg]

[/url]

[/url]

43 mm STAND

[url=http://www.hostingpics.net/viewer.php?id=9134111supportdemachines4800000L1561844914141.jpg]

[/url]

[/url]

-

I do plan on doing just that as well as documenting some jobs that I carry out for customers, the trouble is, finding the time to do this, as I am very very busy, I have a blog which I struggle to find time to post on, but I must make time to share more for sure.

At least could you just tell me :

1 - have you drilled lugs (non predrilled) with a Dremel ?.. YES/NO

2 - if "yes" then did it worked well ?.. YES/NO

Those YES and/or NO wont be much time consuming but very much helpfull for me cause I'm in the process of picking the "right" tools to mod my watches (now I do most of the job with files, sandpaper and my hands).

Envoyé de mon XT1068 en utilisant Tapatalk

-

Dremel I started out with

So you have a Dremel workstation.

Would please write a short review about that tool ?

At least can you tell us :

- have you drilled lugs with it ?

- non-drilled lugs or only pre-drilled lugs ?

A Dremel tool seems much more versatile than a drillpress for average user if one can drill lugs on some watches a year.

Envoyé de mon XT1068 en utilisant Tapatalk

-

Ah thanks dude... good to know it's not worth exploring the dremmel route. I know a guy who drills Seiko in UK and i have never asked if he could do others... I'm guessing he could probably do so? May drop him a line.

BTW ... Despite what I have read and writen I'll probably explore the dremel route.

Yesterday we met for a "watches fab lab" and I tried drilling non-drilled lugs with a drillpress.

Considering the speed we used and the time it took (about 1mn/lug) I really think it could be done with a dremel and it would not "kill" the tool if done properly and with care and "from time to time" (I would not try to drill 2 watches a week with a dremel).

I'll let you know if it worked well or not, or if I killed the dremel.

Envoyé de mon XT1068 en utilisant Tapatalk

-

1

1

-

-

Lume shot.

Sent from my iPhone using Tapatalk

LOVE that lumed insert

So once again ... Could you tell where you git it ?

Envoyé de mon XT1068 en utilisant Tapatalk

-

Update:

The build is currently done for now until more parts are sourced. Until this. I present to you my ultra rare beteeen references. Rolex 6575 GMT Master.

Sent from my iPhone using Tapatalk

WOW !!!

Beautifull watch Sir.

And wonderfull insert ... where di you got this one ?.

Some lume pics would be very much appreciated

Envoyé de mon XT1068 en utilisant Tapatalk

-

1

1

-

-

This is a great post[mention=77791]Manodeoro[/mention] - thank you.

I wonder... has anybody opened out holes using a dremmel hacked into some kind of press?

I already thougt about trying that.

Then I had a conversation with a seasoned member that had tried (n another forum).

In conclusion :

1 - dremmel dedicated drill-stand is not very good

2 - dremmel is not easily fixed on a standard drill-stand

3 - dremmel drillers are good but a little weak for drilling stainless steel

So here's what I think.

For pre-drilled lugs :

Get the same kind of diamond files I used, a good movie or a good episode of your favorite TV serie, a glass of Islay (or anything you prefer) and do just like me I did.

I used the same tools on the bracelet last links and the endlinks and I did not have to open/cut the endlinks.

So it's easy and riskless.

For non-predrilled lugs :

1- mod your bracelet and endlinks first with the diamond files

2 - put the bracelet and endlinks on your case to check where you have to drill and mark it with a very thin permanent marker

3 - buy very good HSS drill bits (1mm + 1.3mm), drilling fluid (Tap Magic or else)

4 - search the forum for a member living in the same area and already owning a drillpress, get contact and fix an appointment

5 - get the watch(es) you want to drill + drilling bits and cutting fluid + a sixpack of cooled beer and go to meet your new friend

6 - enjoy a pleasant saturday afternoon, drilling lugs and sharing mod tricks

7 - go back home with your newly modded watchcase

That's what I'll do next saturday.

We meet (5 forums members)for a "watch mod fab lab" afternoon.

I will learn how to drill lugs with a drillpress (2 cases) and other tricks and show how to make guilt decal dials (and other tricks).

Envoyé de mon XT1068 en utilisant Tapatalk

Rolex Aficionados Please chime in...

in General Discussion

Posted

2 mandatory conditions if you want to keep your SELs bracelet :

1 - the holes you'll drill on the lugs must be perfectly centered with the existing holes

2 - you must enlarge the SELs holes up to 2.1 mm

If I were you the first thing I would do is to order nice 2mm bars so you can check if you have to drill the lugs 1.25 or 1.2 mm (some 2mm bars have thinner spring parts).

Envoyé de mon XT1068 en utilisant Tapatalk