When you buy through links on our site, we may earn an affiliate commission.

-

Posts

805 -

Joined

-

Last visited

Everything posted by sander

-

I see in his ad that he already changed it into 6mm. Too bad I ordered it last week so it will probably come with the 7mm. Also wondering if the cyclops is in the right position or that it's still too far to the left.

-

You need the strap, conversion kit and deployment. You can get is as a complete set from most of our dealers. you just need a 160 screwdriver.

-

If I'm not mistaken, the datewheels for the 7753 and 7750 are different in diameter. Since this movement is a moddefied A7750, the date window on the dial will be in the wrong position for a gen 7753 movement.

-

You don't need a conversion kit. Just the bracelet. The conversion kit is voor the straps. Rubber and leather. I have a 6.5 wrist and the bracelet is not a problem. I think all dealers can get them for you. Andrew has it on his site for $128,-

-

Cape Cod Cloth - when/when not to use

sander replied to qwertyfool2010's topic in General Discussion

well it also works great on gold and silver. I even polish old gen Franck Muller dials with it. after a very soft treatment the dials look fantastic. Even the lume is as new! You have to be very careful though. just a little too hard or too long and the tekst is gone. -

great watch and even beter pics! Funny to see that Josh is calling the stone in the crown a ruby....it's actually a saphire Anyway it looks pretty good

-

swap it for a serviced A7750 movement and your problems are gone. Good luck! PS: I do have serviced one laying arround so if you want I can swap it for you. I only charge you the swapping labour.

-

How to make a better cannon pinion for a Panerai 7750 movement.

sander replied to sander's topic in The Panerai Area

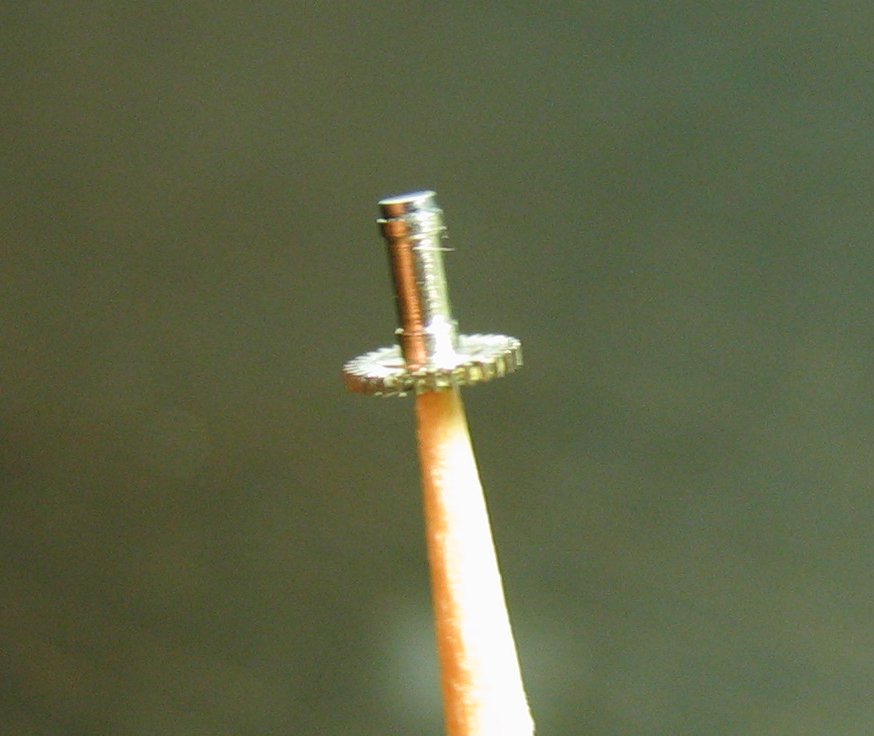

Started with the Dremel After that the needle file After that the needle file covered with 800 sandpaper After that the needle file covered with 1200 sandpaper Finally polishing on the buffing machine. -

-

That is definitely a great combo! Looks very nice on the wrist.

-

How to make a better cannon pinion for a Panerai 7750 movement.

sander replied to sander's topic in The Panerai Area

bedankt maat maar nu naar bed! -

How to make a better cannon pinion for a Panerai 7750 movement.

sander replied to sander's topic in The Panerai Area

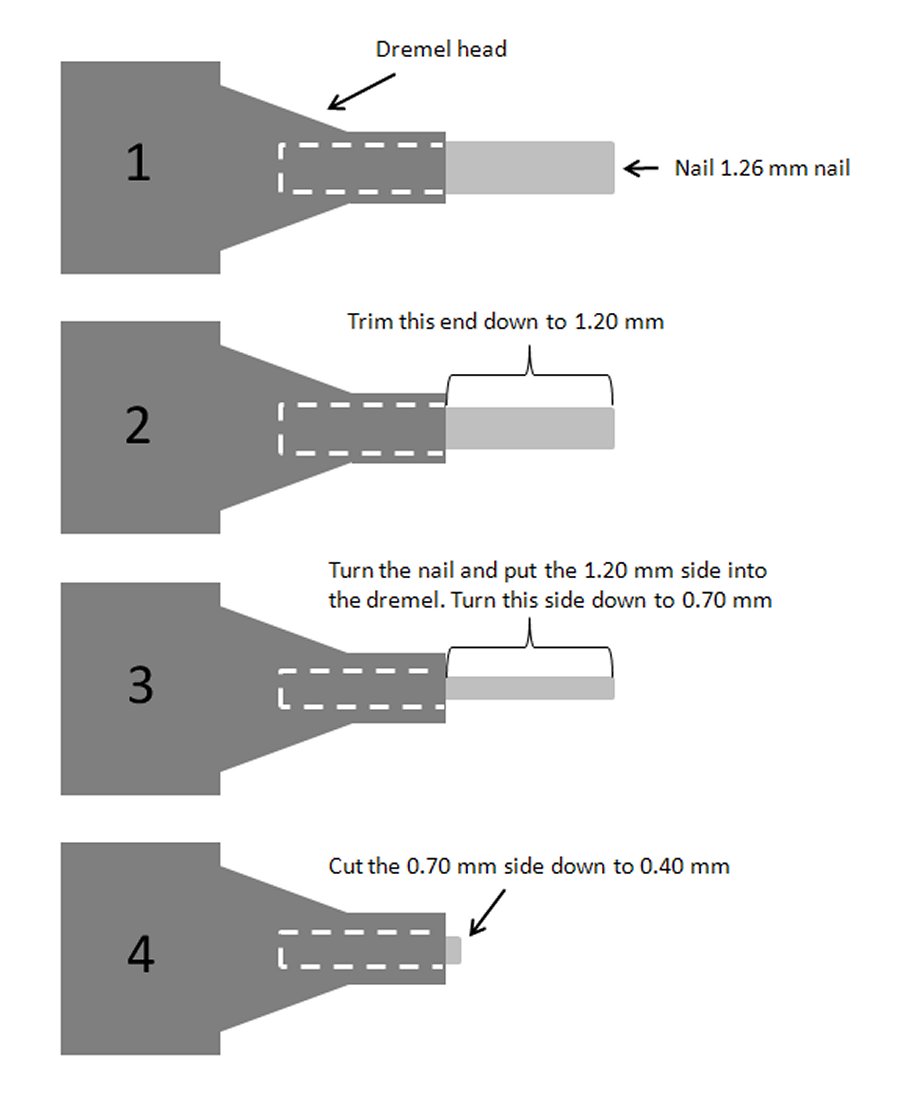

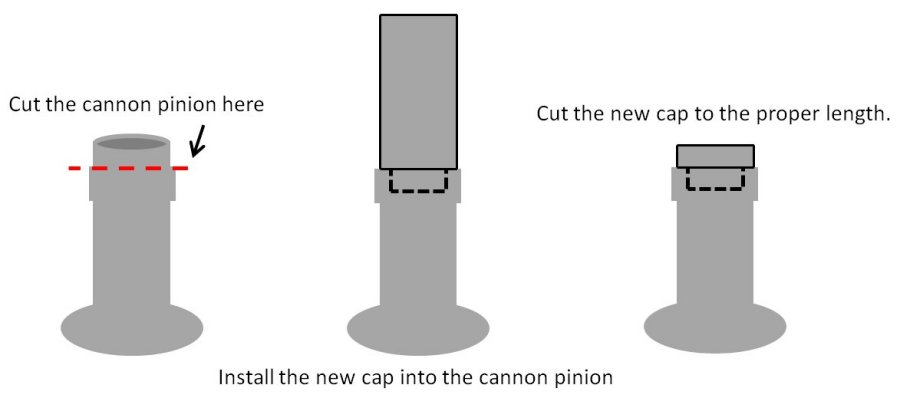

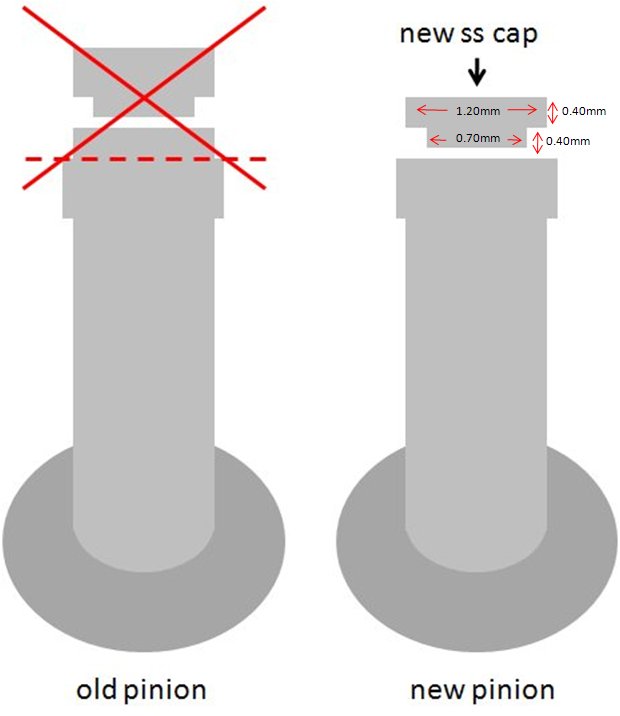

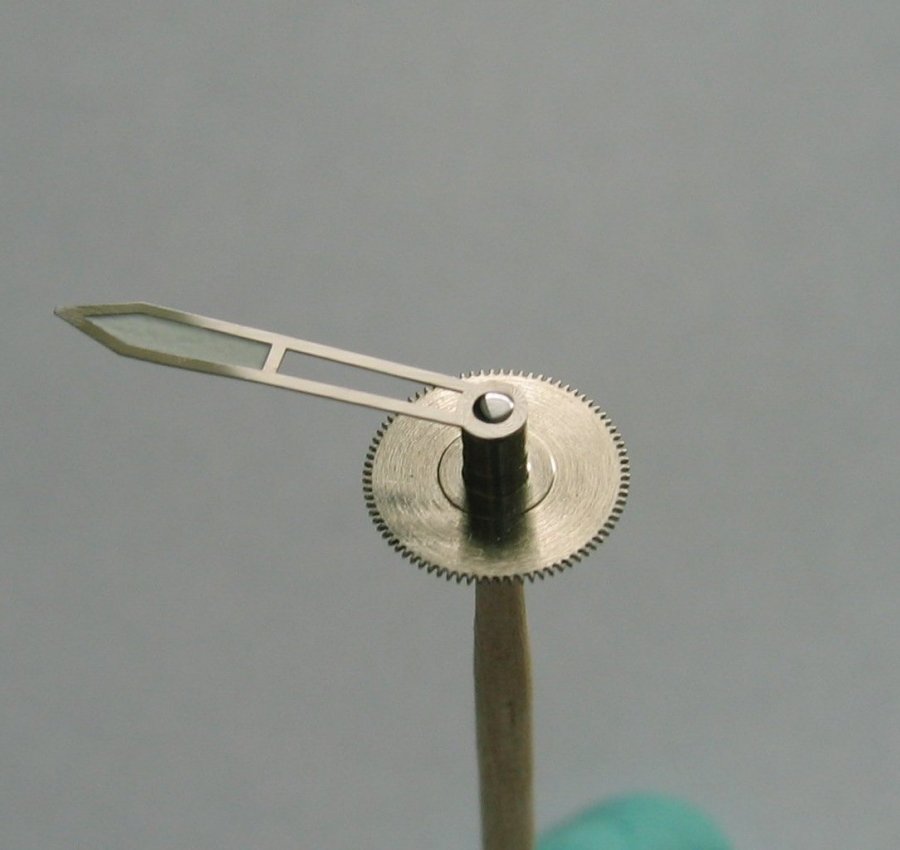

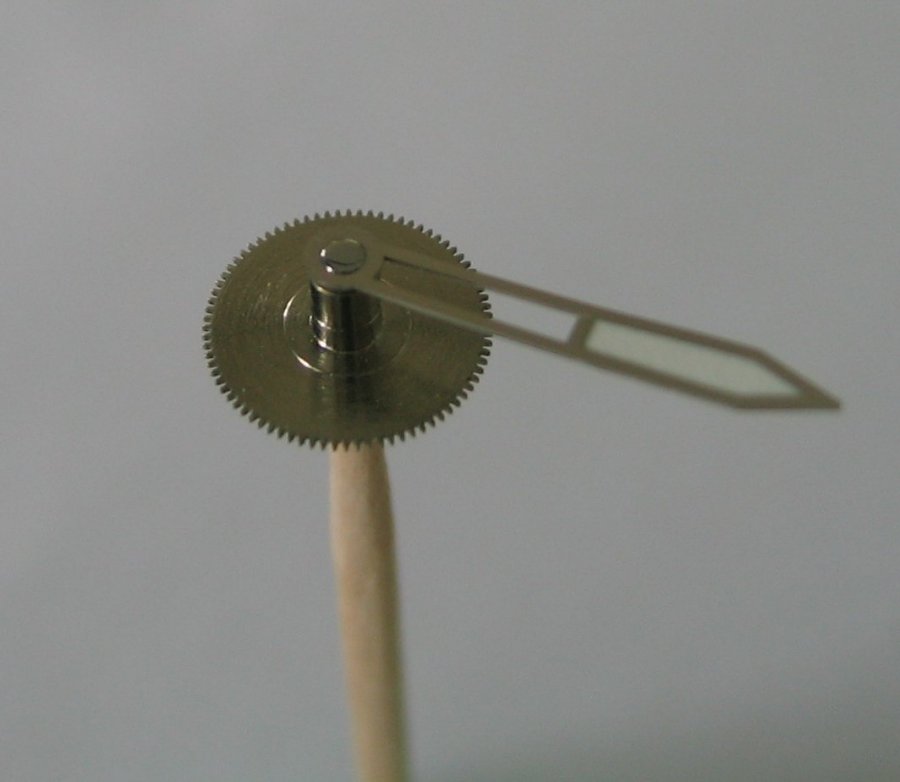

Thanks for all the comments. Since my wife really don't understand what the fun is creating a piece which is almost too small to see, I really appreciate it that you guy's do! I received some questions how I actually cut the cap. Here you go: First I put the nail (1.26mm thick) in the Dremel and used a needle file covered with fine (800 and 1200) sandpaper to shape it down to 1.20mm Then I put the 1.20mm part of the nail into the Dremel and shaped the other end down to 0.70mm Now you have a nail (total length about 0.50 cm.) which is 1.2mm on one half and 0.70mm on the other half. The next thing was to shorten the 0.70mm side down to 0.40mm. After that I installed it into the cannon pin. Now I had a cannon pin with a very tall cap. The next step was to cut down the cap to the proper length and polish it. I made some drawings to clarify it. -

How to make a better cannon pinion for a Panerai 7750 movement.

sander replied to sander's topic in The Panerai Area

THX guys! -

How to make a better cannon pinion for a Panerai 7750 movement.

sander replied to sander's topic in The Panerai Area

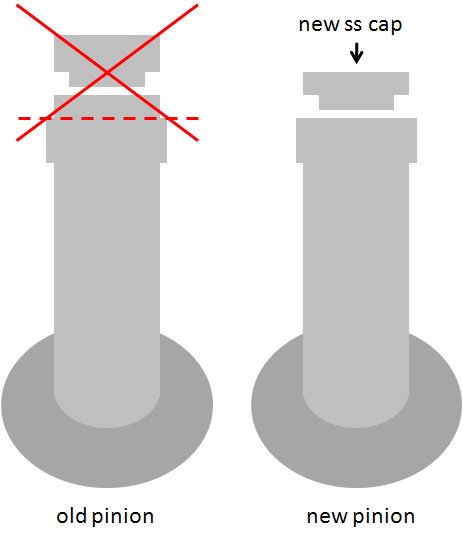

No you do have to cut the pinion as well. (look at the drawing) you cut it down till the dotted line. -

How to make a better cannon pinion for a Panerai 7750 movement.

sander replied to sander's topic in The Panerai Area

Thanks mate -

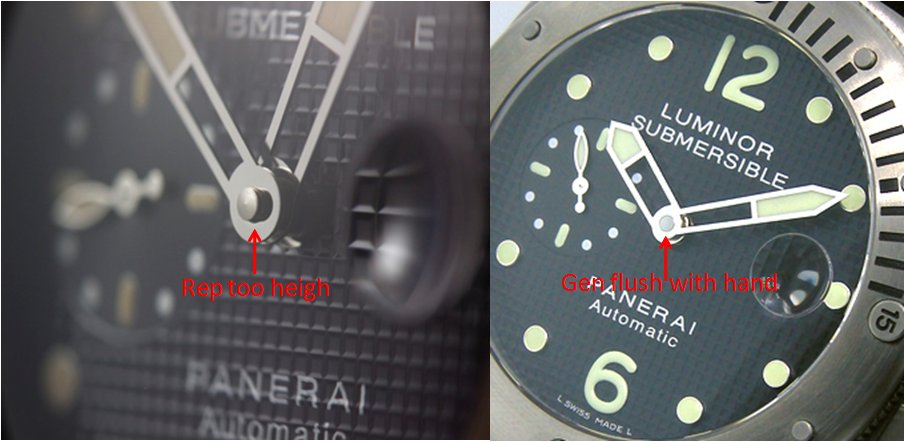

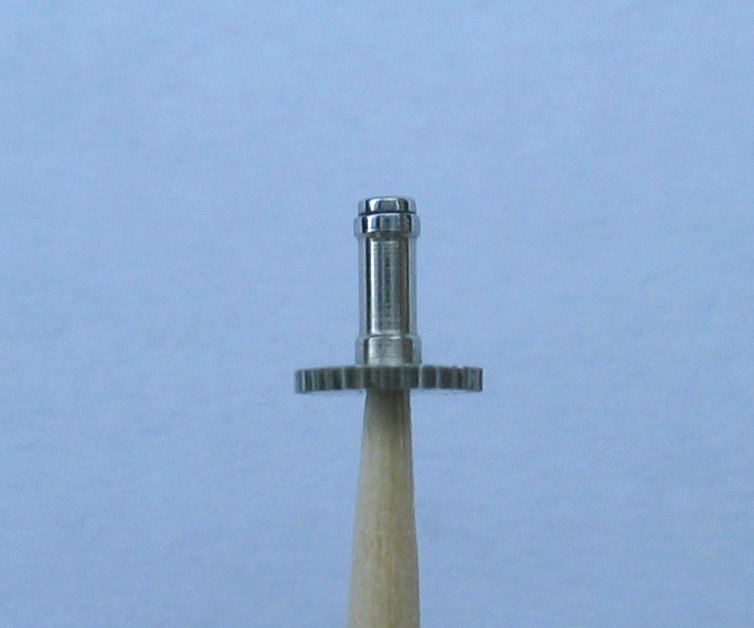

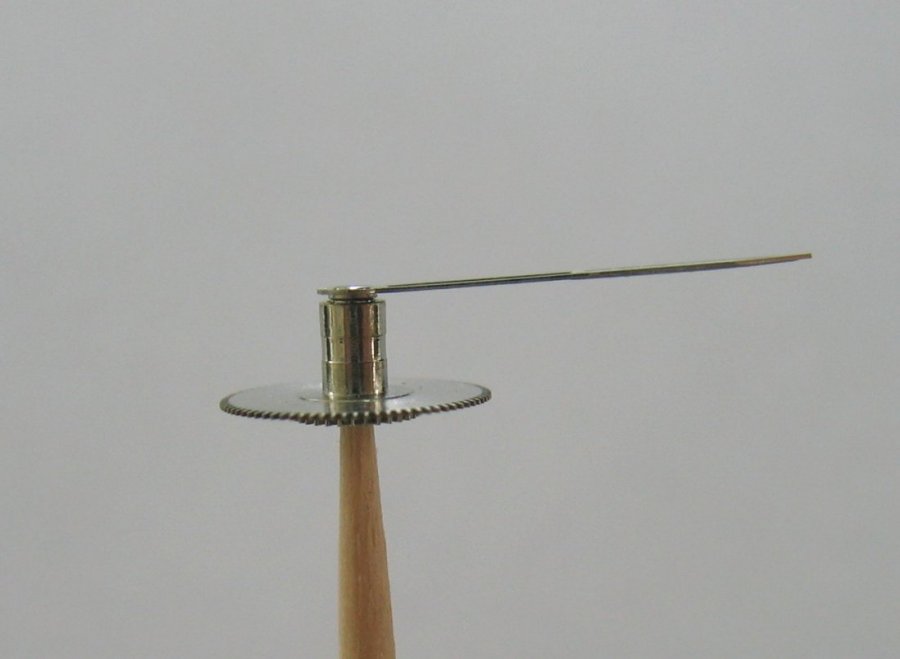

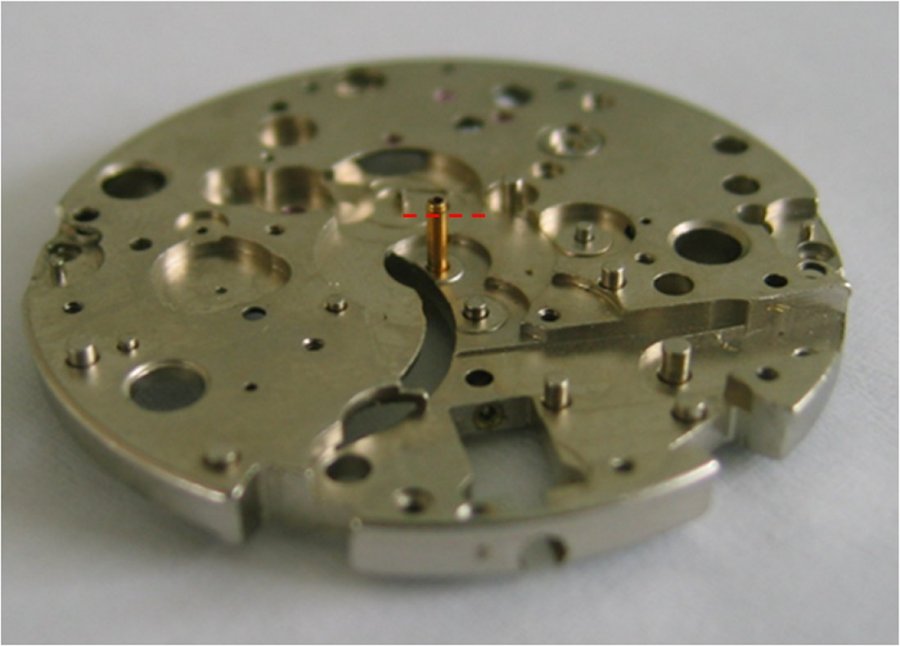

As we already discussed in milesd topic and as Sul said, we don't want to spoil his wonderful topic of his new watch, so I decided to write a new one. For me one of the biggest tells with a 7750 in a panerai, is the high cannon pinion. The problem is caused by the hole in the pinion which is normally needed for the chrono hand. To close the hole, they made a nickel plated brass cap which sits on top of the pinion. If you take off the cap, the pinion is the right height but then you will end up with a hole in the middle. If you sand the cap down, you will notice that you can't sand it enough (because no cap at all is the right height ) and it will also turns yellow because you remove the nickel. To solve this problem, I have modded the pinion with a new stainless steel cap. First I removed the standard cap and cut off the piece that normally holds the hand.Then I made a new cap out of a stainless steel rod. (it was actually a 1,26 mm nail ) I made it a tight fit so that the cap is pressed in place. (see drawing) You also have to cut a little piece of the brass rod of the main plate. Because the cap sits lower, you cannot install the pinion correctly over the brass rod. It's not a problem to cut it down a little because this rod holds the jewel for the chrono seconds hand, which is not needed in this case. If you cut off just a little there is enough rod left to support the pinion. It's a pretty tough mod because of the size it's difficult to work on. Another issue is that you will have to completely service the movement because you have to cut a piece off from the brass rod of the main plate. Since I don't believe it's possible to do this without getting filings into your movement it's better to give it a service as well. Actually, a service is always welcome Cheers! Sander

-

-

Yes it does. it seems to be even more than usual. You cannot sand down the cannon pin because it's made out of brass. If you sand and polish it, it will be yellow. besides that, what you see in the pic is a little cap which closes the hole of the standard cannon pin. when you remove this cap, the height of the pinion is correct but then you will end up with a hole in the middle. I removed the cap and shortened the pinion. I made a new stainless steel cap which is lower than the original cap. Voila!

-

thanks for the extra pics. I'm a little concerned about the cyclops. Like someone else wrote before, it's placed too far to the left and it's 7 instead of 6mm. So it seems that the crystals are leftovers from other than 7750 movements I've heard that the crystal of the ultimate 199 does fit. 6mm cyclops and placed at the right spot! This would be nice because I have one

-

Yep, it's great looking. Can you show me a pic of the buckle. I orderd the D model and I'm not sure if I have to get a gen buckle for it. Thanks!