-

Posts

1,262 -

Joined

-

Last visited

Posts posted by mjmurphy926

-

-

I would like to use the watch during the week for working with a suit but also for the week end.

But first of all i would like to have the more accurate and close to the gen.

Hey Silicate007,

I think both watches are great. I have the SSD and love it. I also think a lot depends on your wrist size. the SSD is 40mm while the SOH is 46mm. Can you wear a 46mm watch? If so, I'm sure you wouldn't disappointed.

BTW, I see this is your first post...

There is TONS of great information on RWG. Enjoy!!

As a new member, you may be interested in the

-

Yep...It sucks that the case is polished.

I wonder if there is a chance they will fix the finish soon. I agree that it seems like a lot of work to go through making a ceramic case and then get the finish wrong...Doesn't make much sense.

-

Not a bad price. Too bad the dial isn't better.

http://www.trustytime88.com/index.php?main...roducts_id=3102

-

-

Fantastic work and its great to follow your Progress. I am expeting an entry level 111H from Silix next week. i already have a good sapphire and the V CG. Just need to source the swanneck and some AR, Relume and a cannon fix.

However yourself and Athan are giving me great guidance with your posts.

Thanks Seltea...Glad I can help. Can't wait to see yours.

-

Don't forget to add the correct shape of the 2, 3, 6 and the yellow offwhite font for the perfect H-series dial......

Love the strap!

Yep...Thanks for pointing out the other flaws scoobs...Am I correct in that, for now anyway, the only options for a 111h (sandwich) dial are cartel, DSN, or gen? Are there other options I am unaware of?

I love the strap too. Thanks. It's Strap Culture legend II #7. I have a few SC straps and I love them all.

-

Do you know anyone who carries a PAM 111H dial wilth the "L swiss made L" spacing that is like the gen? I think you need to update that too.

Hey Pete,

I agree. I'd like to see a dial with L SWISS MADE L a little lower and the As have the cross bar a little higher. DSN used to sell a pretty nice dial, but his latest 111h dials look worse than the one on my watch.

There has been talk of someone (sorry, I don't know who) on RWG putting together a project to make an accurate 111h dial. I really this comes to fruition.

Thanks for the feedback,

Mike

-

I'm working on a 111h project that I plan to document here.

It all started with Andrew's entry level $158 111h.

The first thing I did was to move the crown closer to the case. See here:

http://www.rwg.cc/members/index.php?showtopic=76968

Next was to swap the low end Asian movement with Asian dagger swan neck movement. I had purchased a cheap unbranded PVD with dagger swan neck on ebay and I was thinking about using the movement from that watch, but I decided that I wanted the Panerai engraving on the bridges, so I purchased Andrew's $228 177h and swapped the movements between the 2 Andrew watches.

While attempting to regulate the movement, I realized that I couldn't get the swanny to slow down enough, but I remembered that I was able to adjust my unbranded movement to run fast or slow, so I should be able to get it within +/- a couple seconds per day. So, I swapped the bridges between the two swannys and installed the dial and hands that came with the 111h onto the new combined movement. Then I installed the movement into the case. Although the swan neck adjustment screw is too short to allow adjustment throughout the full range of the scale (common to Asian swan necks), it is long enough for adjusting where it's needed. I currently have it regulated to -1 sec every 2 days (1/2 sec per day). The only issue I have with the movement now is the paint applied to the engravings is pretty sloppy, but I'm reasonably confident I can clean it up.

A few new pix:

And the new movement:

Next up is a new sapphire crystal which is on the way from DSN. I'll send it out to one of our AR gurus for treatment (Just gotta decide if I want single or double).

I am hopeful that I can buy one of the awesome V CGs from Kostas. We'll see. I'm also planning to get one of the RWG crowns from T.

I hope to have these mods complete by the end of September because it's scheduled to go to Zig in November for re-lume and cannon pin fix.

More to come...

-

I'd love to be able to clean this up. Anyone know how?

Thanks,

Mike

-

Very nice!!

I may try a PVD next (as soon as I'm done with current 111h project).

-

Lemme just tell you that the dirty work we do in the basement on this site, is no joy...Gotta wear goggles and sometimes, after TT has been down there, I even wear a gas mask, if you know what I'm saying

yeah, I know what you're sayin'

yeah, I know what you're sayin'

-

-

ello govnah!!

OK...That was a pretty lame attempt of a yank speaking British (kind'a like Madonna)...But seriously...

-

Mike, Your description makes sense, and is sorta what I figured given its location on the movement. The post from P4GTR is interesting. From your post it seems, at least on some movments, it is functional. Thanks, 550bryan

Mine is definitely functional. As far as I know, all the screws work. The problem is, that the screw is too short and doesn't allow for full motion throughout the entire adjustment range. It also seems like it is usually screwed all the way in. Mine does give enough range to fine tune it though.

I wish someone would produce replacement screws that are longer. However, the screw is soooo small, I think it would be pretty hard to replace it. But I'd like to try.

@P4GTR, if you ever have your movement uncased, try to turn the screw counter clockwise. I'll bet it turns.

-

this is what i meant by rounded VS straight edge. maybe yours are like this in person, just cant see it on the photo.

CGs are a matter of personal opinion for most i think, so if youre happy thats all that matters.

the gen shows like theyre rounded around the crown, and it appears the same in the tutorial. not like a pointy straight edge.

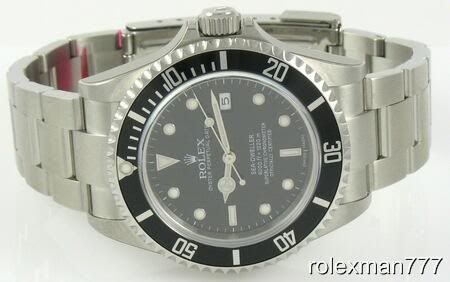

I guess it depends what gen pix you look at. The gens in my local AD look like this gen pic:

That is what I modeled mine after. Rolex has a way of slightly changing things, like CG shape all the time. You're right, it's up to the individual to decide what they like best. I just went with what I saw in person.

-

I.m a nubie, so sorry if this is a dumb question, but what is the difference or function of the dagger swan neck that seems to be present in the better movement? Thanks

The function of the swan neck is to fine tune the regulation of the movement.

In order to regulate the movement (make it run more accurate) you meed to move the dagger or pointer up or down (+ or - on the scale) to speed it up or slow it down as necessary. It only takes very fine movement to make a difference of several seconds per day. If you look closely at the swan neck, you will notice that on the top side, there is a screw that touches the dagger. The swan neck wraps around from the screw side to the bottom side of the dagger putting pressure on the dagger. So, you can micro adjust the regulator by turning the screw slightly clockwise to slow it down, or counter clockwise to speed it up.

It really works great. I was able to make mine run about -1 sec every 2 days (or -1/2 sec/day) I'd rather see it run a little fast, so eventually I'll pull the movement and turn it about 1/8 a turn counter clockwise to speed it up slightly.

I hope this makes sense.

Mike

-

Very Cool!!

-

always looking for nice pieces to add to my existing collection.

Thanks

Are you sure you're not a pimp?

Welcome!!

-

Mine is pretty boring. Just a login ID I was given by a vendor to their support site about 10 years ago. I have been using it ever since on forums.

first initial, middle initial, last name, random #s

-

Interesting that you should mention that, BT. You see, my name actually comes from the two latin words admastatulos which means extremely and inistatis which means cool guy

Yeah...We can tell by your picture how cool you are...At least you had the sense to wear eye protection when you went sh!t divin'...

Yeah...We can tell by your picture how cool you are...At least you had the sense to wear eye protection when you went sh!t divin'......Actually, it cracks me up every time I see your avitar. It looks like poop on the face and the expression is priceless. Almost like he just pulled his head out of his A$$ and is surprised to see someone watching him.

-

WOW!!! That looks amazing. I still have a little ways to go...Can you direct me to Gio's tutorial? I have been using the other one mentioned on this thread already and it does not show such sharp edges.

As for the pearl, I lost it tonight but it turned up and I glued it in place already. It is aftermarket and looks a million times better than what came on it. Thanks for the feedback!

Thanks.

I should probably tell you though, that I did do something in addition to what I read in Gio's tutorial.

Once I was happy with the amount of material removed, I noticed that the part I sanded was flat and didn't follow the radius of the inner part of the CG. So I took a strip of 220 wet/dry sand paper (the black stuff) and, with the crown in place, I ran it between the crown an CG (with the abrasive part toward the CG, obviously

). This not only rounded the flat spot to match the inner CG, but it also ensured that the gap was even on either side of the crown between the crown and CG.

). This not only rounded the flat spot to match the inner CG, but it also ensured that the gap was even on either side of the crown between the crown and CG. Two things to be careful of though...Be sure NOT to push the sandpaper down toward the watch case or you will cut a groove in the corner...And, be sure to remove the crown and clean/grease the gaskets when finished.

Good luck,

Mike

-

Not sure if the half dot would bother me, but I'm thinking it probably would.

Hey, is that real AR? It appears to be absorbing reflections.

EDIT - Sorry, I just re-read your post. I missed that part about excellent AR. That's good to know.

-

i say keep going, and round it out a bit so its not such a straight edge.

found this for you:

ENJOY

http://www.rwg.cc/members/index.php?showto...5712&hl=mod

lots of pics for reference and a how-to method

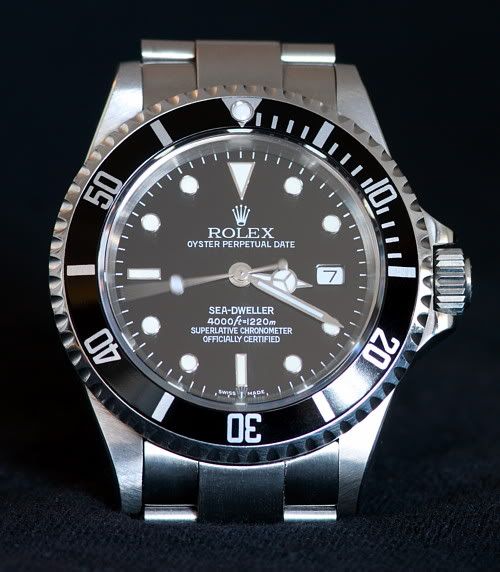

I don't mean any disrespect, and I'm certainly not a great modder like some around here, but I'm not quite sure what "round it out a bit so its not so straight edge" means. I think you want it as straight as possible with as sharp of inside of corners as possible (where the CG meets the case). I think this is the area where a lot of people have trouble. I was able to get that corner pretty sharp. Mine are by no means perfect, but I compared to gen and they are pretty close.

I followed gio's tutorial. It's a great tutoral. It took me several days to get them where I was satisfied. Just take your time.

Mine for reference:

BTW - I would replace that perl next

-

EDIT - Not sure how this got here.

See next post below.

See next post below.

A gift

in Introduction/Rules/Support

Posted

Hey Eric, Welcome to RWG!!

There is TONS of great information here. Enjoy!!

As a new member, you may be interested in the