-

Posts

850 -

Joined

-

Last visited

-

Days Won

1

Posts posted by preacher62

-

-

The keyless works parts are the same, also the part no. 721 is the annular balance and it works in everything from 2801 on thru 2836. The 24 and 36 both beat at 28.8 bph.

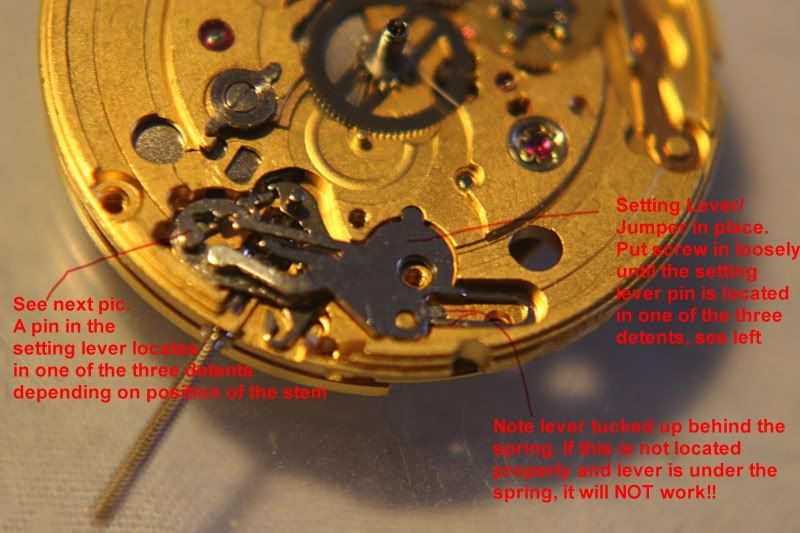

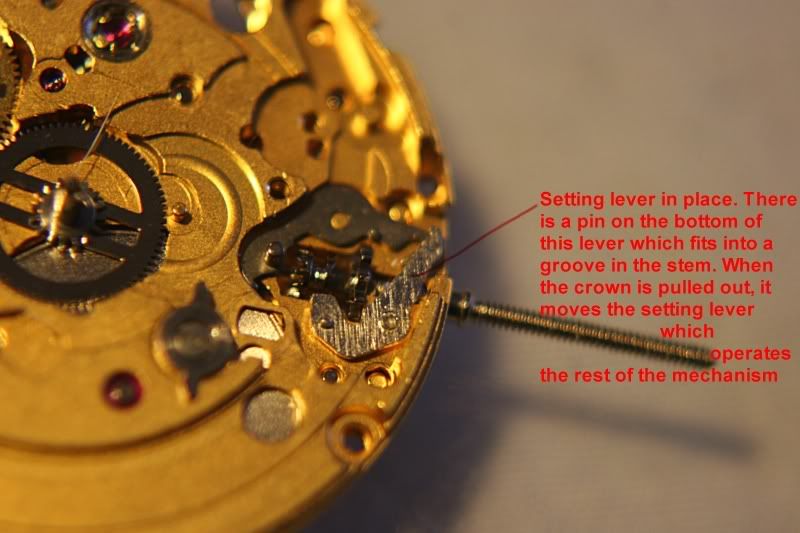

Are you sure that you are setting the parts in function before you put it together. In your photos at the top of this post, I can see that the set lever and corrector lever are not in the proper position to one another. There is a small pin on the point of the set lever. When the kw is placed in setting position that pin is to fit into the hook-shaped slot on the corrector lever. Also ther is a hook shaped spring on the bridge that covers it all and it has to be manually placed into position against the tab on the end of the yoke. I think I have a pic of that. If not, things to do not work predictably.

There are three pins on the bottom of the set lever. The large one sets in the hole in the plate and provides the pivot. The one toward the middle rides in the slot on the stem, the one on the end works the corrector lever.

Note that this is the kw in setting position (stem pulled out to second detent.)

-

1

1

-

-

It probably is, but I think safer to use Paypal. I have been scammed and Paypal went to bat for me. They refunded my money and then persued the perp.

When using PP, follow carefully the instructions of the dealer. You CANNOT, for instance, put in the note: "This is for one each, fake Rolex 16610."

Edited for correction of bad mistake!

-

I PM'd TC one week ago today. Still waiting.....

-

Oh, gag! No straps - PERIOD!!

I agree with J. Somehow a Rolex just must have it's intended bracelet. I have a newly built 16013 on a dark brown genuine simulated alligator (with even a Yuki buckle) but I have a yen for a jubilee in 18K and SS like it is supposed to have.

-

The pearl is wrong and the lume needs to be redone

Yeah, and the hour hand is not exactly right...but the M's line up...

I saw these and I want one.

-

I PM'd TC two days ago. Is there another way in which you guys are in contact with him?

-

I've had complaints about the sonic boom made by parts exceeding the speed of sound in unknown directions through the house. Fortunately, my Lady is a surgical Nurse and can find a 7-0 prolene suture needle on an OR floor all day long, so teeny-tiny watch parts are no sweat for her. She's found `em all. And there is no truth to the rumor that I've dropped a few on purpose just to watch her do it...

Yeah...that was me. LOL

-

If you want to save $$ when starting out, you can go the 'Seiko route' with 4 basic lubricants...heavier train oil (such as Moebius 9020), a thinner oil for escapements etc (like Moebius 9010), grease (KT 22 etc), and maybe Mobieus 8210 for mainsprings. You might also need pallet fork/escape wheel lube such as Moebius 9415.

You can change brands and save a whole lot. Zenith oil for instance is highly respected and the cost is a fraction of Moebius. You can buy a bottle of synthetic Zenith oil big enough to get drunk on for a few bucks. Zenith Vacu-Seal is one of the best silicon gasket lubes too.

You do not need a whole lot of 'watchmaker stuff' to do a good job. Imho, you need a steady hand, a good eye, good optics, a few good tools, good light, good instruction, a LOT of practice...and a HUGE sense of humor about mechanical watches.

...and I mean HUGE!

I have an L&R Ultramatic/Ultrasonic cleaning machine but good used examples cost too much now that mechanical watches are popular again and they are hard to keep up (vacuum tubes, hydraulic pump, relays etc). Something smaller and simpler is better for cleaning jobs now and then. Even an old L&R 'milkshake maker' is pretty good if you can find one for a good price.

I have been servicing my own movements for several years and it is the movements that lead me to this rep forum. But...it is the sense of humor in which I am sorely lacking. I would recommend that anyone who wants to service ETA movements, for instance, check your click spring and shock springs and make sure that you have some extras. I, quite often, will launch one into the ionosphere. I am running almost 99 % recovery now with a new vacuum cleaner.

-

Do gen inserts fit the noob subs?

They do not fit straight up unless the bezel has been redesigned. The gen insert (or one from a parts house) has to be milled down just a little. There are several totorials on this forum that explains the process. Not sure I would use a gen insert for that.

-

For the low, low price of $28,800 Euros you may have this entire package for your own...plus VAT.

Place your order within the next 10 minutes and you will also receive a Snuggie, in your choice of colors, at no additional charge. But you must act now!

-

http://www.rwg.cc/to...ica-rolex-gmts/

Check this...

The noob is out of production a long time ago..Maybe sometime in the future ....

If you look at the coronet on the clasp of the OP's link, it looks exactly like all the Noob clasps that have ever been made. I have 2 of them.

-

So check my arithmetic: if a 2824 has a 1.8 mm stem height, and one in a stilty spacer leaves about .4 mm clearance to the dial glued to the top of the spacer, does that mean the stem height on a 3035 is 2.2 mm? Meaning a 2836 with its 2.25 mm stem height should fit with the stem .05 mm off center in the hole?

Sounds right to me. I am going to try that movement again. I would rather use a 36. I went with the 16000 case because of that. The 1600 normally calls for a 24. The date wheel spacing is better and the 36 just has a completely different and more robust date-changing mechanism.

By "stilty" spacer are you talking about the dial spacer? Stilty is normally noted for his enlargement ring...movement spacer. I have a movement spacer that is perfect. I had to mill a couple of places where the case clamps cross it but other than that, it works great.

-

The advice that I have from one of the great ones...Ali, I think, is that a 36 is what is indicated for a 16000 case. If the 36 will work, I will work with it some more.

-

I think the issue is dial to DWO spacing here, use a thicker Dial spacer

Faxr, that isn't the problem. It is the other way. The tube is near the movement side of the tube as opposed to the dial side. I would need to take some space out against the rehaut, not the other way around.

I really appreciate all this discussion from you guys. My 2836 is factory stock. I think that I have solved the problem with the 2824.

-

So for the 2836, with a stem height of 2.25 mm, the stem was up against the back side of the hole? What S/N range is your case?

I'm very curious about this as I am just about to start a 16013 project.

S/N R378192 I have a 2824 in the case with the dial attached to the dial ring with double-sided scotch tape and the stem is perfectly centered in the tube. With the 2836 I can mount the gen crown but then cannot pull it out and in properly. To tight against the tube..

-

All modder's comments are welcome.

What is the secret to making an ETA 2824 work properly with a date wheel overlay. I have tried everything. I have used double-sided tape on the dial ring to give it some spacing. I've tried a layer of tape on the date wheel and I have even tried it with nothing extra.

It seems as though the dwo rubs against the parts on the movement, unlike a 2836.

I have a gen 16013 case in which, upon advice from this forum, I intended to use a 2836. This 2836 does not work in this 16000 case as the stem is almost against the side of the tube. Others must have a different sort of 2836 or a different sort of 16000 case.

The 2824 fits the case perfectly, but just will not change date properly. Without the overlay the date ring moves cleanly and snaps over.

Please help me or I will sell you a beautiful 16000 Rolex case and dial.

M

-

Hey, I have one just like that in the box. I'll take $150 for it.

This guy must be smokin' something. He says it is 18K.

-

Round top 3 and open 6/9 are correct for the 16013/4 and other 3035's. But one of my 16800s came with a service DW and it was small font and closed 6/9s. I managed to get a NOS DW with the open 6/9s and it's much larger fonts. Looks 100% better under the cyclops. I guess rolex could give a rat's a$$.

Where to find an old style DW these days, I don't know. My second Frankenjust came w/ a DWO with closed 6/9s and I just left it on there- who's gonna know!

My 16014 had the old cubic works DW w/ the open 6/9s but those are long gone.

JMB might be your best shot, he's made some DWOs lately, I believe.

Thanks much for all the information. I have a modern dwo and might just use it. Or...I could go with your first logic and use my flat-topped three dwo..."who's gonna know." The people that I know who are gen Rolex owners know nothing about a Rolex. I could tell him that is has a 350 shortblock in it and it wouldn't make any difference. He doesn't know what that is either.

-

Well you ought to show us what you found, because I would have said no. All I've ever seen is is round top 3s and open 6s and 9s. Later DWs would even have closed 6s and 9s- Rolex doesn't care.

Ali,

I saw this one...

http://www.ebay.com/...=item2318fbf243

And this one...

http://www.ebay.com/...=item3a6f603010

Then there was this one... I think there are a lot more.

http://www.ebay.com/...=item2a18d3575a

Oh, sorry, Ali, I just re-read your post. I do not know about flat-topped 3's. I am building a 16013 and have a case that is on the way. I have a dwo that has flat-topped 3's and wanted to use it. Guess I better use a more conventional one. Do you know where I might get a dwo with round-topped 3's and open 6's and 9's?

Might they have had a service replacement that is closed 6's and 9's?

Thanks for response!

-

My question for the experts...did a 16013 with a 3035 ever have flat-topped threes and open 6's and 9's or was that a 15XX feature?

Thanks in advance!

M

Disregard...I answered my own question by looking on the Bay. It did! Great!

-

You'll be much happier if you do business with Gary Clark. He's a good man and a good friend as well. PM him through Ebay, tell him you are a member here. I got him set up as a 'Trusted Dealer' on RWG1.1, and I think he should be here as well.

I buy from Clarks when I can but he just doesn't have the wide range of stuff that WholesaleOutlet has. I have purchased many time from them and have not had one problem. I just received a set of 455B endlinks for 2mm springbars and while I had to trim just a little they work perfectly. I understand that his bezel assemblies do not fit all (supposedly) 1:1 cases.

-

-

This is using an ETA or China-made movement with stock date wheel positioning. On a gen DJ the date window is nearer to the center of the dial by about 1mm and is longer, horizontally. This is the reason that we use a date wheel overlay with near Rolex factory fonts. This date window is in stock ETA, or other, position nearer to the edge. That's why it looks funny.

-

Preacher, see if the back off the rep case fits and if so I'll try one of the plain backs I have to see if it fits that case...

I tried that and the opening on the 16014 is much larger. The rep case back just falls in...the threads just bypass each other.

Thanks for that new drilled case for my 1016. The drilling is nothing short of factory. I'm just waiting for some endlinks that take 2mm spring bars. When I tried to drill the endlinks that I have there was nothing there to drill.

Hack problems and eta 2836 gmt movement help needed

in The Rolex Area

Posted

If you have access to an ultrasonic cleaner you can fix the reversing wheels up in no time. Sometimes you can just rinse them good in denatured alcohol, but not usually...once they start sticking. See where the red arrow is pointing in the photo below. You want to clean these impecably and then pick up the tiniest drop of oil you can get and touch it there. Then do the same just opposite of that. Resist the temptation to touch it again. Less is best in this place. These reversing wheels are very sensitive to over-oiling.