When you buy through links on our site, we may earn an affiliate commission.

automatico

VIP Member-

Posts

3,180 -

Joined

-

Last visited

-

Days Won

153

Everything posted by automatico

-

"Shooting that watch against that background absolutely nails it! Well done." Thanks! A lucky shot. I do not know which I am worse at...watch 'mechanic' or 'photographer'. Probably a tie. Ha! Also, thanks to Tribal and swdivad! Proof I can't take a pic...manual wind Fortis from the 1940s/50s: Original with stainless 32mm steel snapback case, 17 jewel movement (iirc on 17j), radium (!) markers.

-

I saw the old school SD thenightwatchman had for sale and remembered I saved a few from back then. Here are two from 'River' 15 or 18 years ago when he was selling all types of watches: Both NOS with some of the original plastic wrapping still on the bracelets. New Swiss ETAs for sure and pretty good bracelets with solid mid links, sapphire crystals etc. I have two more from years later (not from 'River') with hollow mid link bracelets, case numbers/letters etc. I'll post them later on. Here is where they have been for all those years: All pics taken 10-21-23.

-

- 2

-

-

-

...might make my 'collection' worth more. Ha! It's a Crazy World out there. eBay item 204489066382 Aftermarket / Vintage Rolex Explorer II 1655 Full Case with Case Back and Crown | eBay Carefully aged to look like it fell out of a cement mixer.

-

JSebWC: Bring this back from the dead with a few recent builds. A '16 with a hair puller bracelet! That takes me back. madasboot: The 6350 dial is being made in 28.5mm and not as a 27.5mm as per original and it is not being done proportionally, being the difference (0.5mm) added to the edge. This makes the dial unusable in a gen case, ...and in a rep case the chapter is too far from the rehaut. Regular explorer cases are also not accurate for this model. Yep. Besides that, the 6350 has the A296 movement. An A260 or A296 makes my head hurt just knowing one is in the vicinity. Some info: A Complete Guide to the Vintage Rolex Explorer | Mark Littler Ltd

-

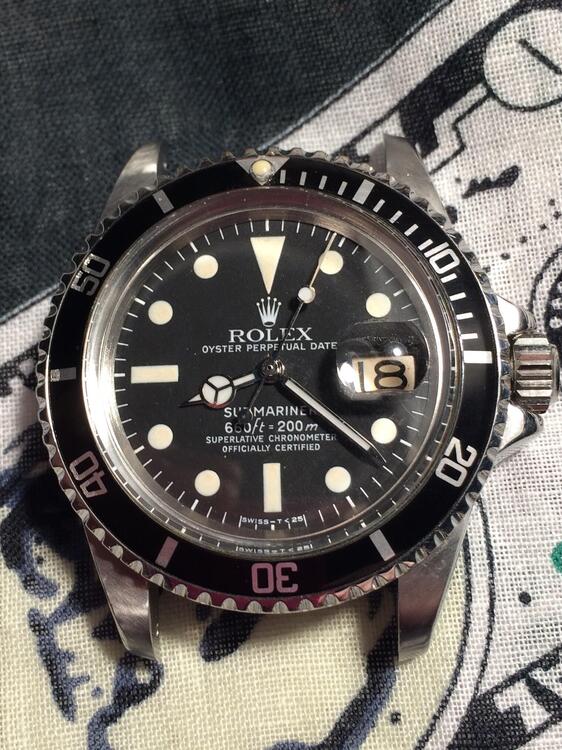

MBK '5512' with ETA 2879 on 9-9-2023... Background right is a '5513' with Hattori/Epson VH31A (14400 bph) quartz movement. Background left is a '5514' from 'Paul/Abay 15 or 17 years ago with ETA 2846.

-

Freddy is right...the 603 is basically a 6.0mm crown that uses a 5.3mm case tube. Genuine 162xx DJ all use 603 type crowns with 5.3mm 'no broach' case tubes. 'No broach' = case tubes do not need to be broached to accept the crown post like older case tubes. If you have a 162xx type watch with a 5.3mm case tube and do not have a 603 crown, you can use a regular 5.3mm crown until you find a 603. I saved quite a few used 'take off' crowns but ended up with very few 603 type crowns, stainless or gold. Most are regular type gold 5.3mm and regular 6.0mm gold crowns. Many need to have the crown post/clutch assembly swapped out because of a defect or needing a crown cap with better threads in order to make a good crown. A pin vise will usually remove the crown clutch without damage but if it slips, it can rough up the crown post. I use a 'WW' lathe collet in a 'WW' type lathe to remove the crown post by tightening the collet on the crown post with the drawbar, hold the lathe pulley with one hand, and unscrew the crown from the post/clutch assembly using padded pliers in the other hand. All the above deals with crowns with 'crimped crown caps'. Later 'monobloc' type crowns have a one piece cap. 'Crimped crown cap' = the crown cap is a separate part crimped over a nickel silver base. They are easy to spot from the back side and earlier 162xx watches will have crimped crown caps unless they have been swapped out. The crowns pictured in Freddy's post above both have crimped crown caps. Monobloc type crown... Here are the 'takeoff' crowns a couple years ago, maybe used 6 or 8 since then... The complete thread from October 2021... "Are those holding 1030 movements? If so I get the first two..." - The Rolex Area - RWG

-

Another reason to wear a replica... A 60 percent increase in watch theft in 2022. Rolex Thefts on Rise as Luxury Watches Worth £1 Billion Missing | BoF (businessoffashion.com) I hope no one steals my Mickey Mouse project watch. 9-5-23 F1 driver chases down alleged thieves who stole $500,000 watch (aol.com)

-

I took a day off from 'important work' and today's time waster project is a stainless 40mm Mickey... Movement and dial originally came in a tutone plated pot metal case, now in a new goldtone Caravelle stainless steel case, it was an exact fit. The 'gray metal' pot metal case was beginning to corrode and I do not know what it is made of but once it starts corroding, it travels rapidly. The mouse was loose on the dial so I glued it back on after drilling a 1mm hole in the dial under each foot so the glue could reach it from the back side. There were two little dial feet on the mouse body to index the dial and hold glue but none on the feet. The glue they use to mount the mouse comes loose after a few years and the watch is probably from around 2005 or so. The Disney case back fit like a charm too, this does not happen very often. The Caravelle had a Miyota 2035 type date movement and the Mickey has a Hattori PC21 type movement with date. I used the Caravelle movement spacer and crown in the Caravelle case. The Caravelle crown has the O ring inside the crown and the Mickey had the O ring on the crown tube so the Mickey crown with 'mouse ears' could not be used. Next time I'll change the case tube to accept the mouse ear crown. The Mickey watch and movement were originally made by SII (Seiko) and the Caravelle watch/movement were made by Bulova (Citizen).

-

See though Rolex dials "for service adjustments"

automatico replied to Ronin's topic in The Rolex Area

'V' series. Thanks! -

See though Rolex dials "for service adjustments"

automatico replied to Ronin's topic in The Rolex Area

I wonder if the Clone movements allow for this? Don't know, never looked one over but they probably do. I need to buy one and check it out, but do not know which one is supposed to be 'the best'. Need to read up on them. I'll give this thread another look: SH3135 parts - The Rolex Area - RWG -

I have a Rlx '15200' that Stilty put together using one of these adapters and a nos ETA 12892 (early version of 2892) using genuine 15200 case, dial, and modified hands:

-

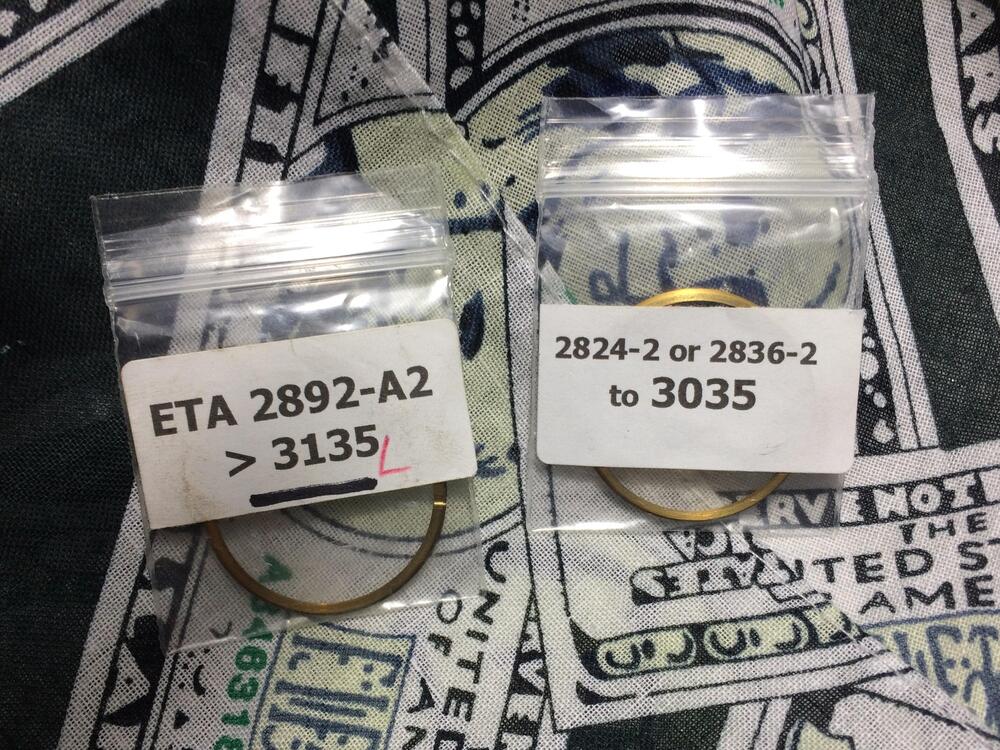

Finally found the 'Stilty Spacers' from 2008. Just a guess...spacers below are probably for putting an ETA 2836 date movement into a Rlx 1570/75 date spec case, have not tried one yet but this is what started the spacer project when Stilty had an oem spec Yuki '1680' case. Btw...it ended up with a Rlx 1570/5 in the Yuki case before he parted it out and traded the case to me...then I traded the '1680' case for a Phong '1655' case. Just the facts...each adapter has to be made for a specific ETA movement/Rlx case combo such as above or an ETA 2824 with date works removed into a Rlx 1570 no date case, 5512/13 etc. It is not the same as using a generic brass spacer in a movement/case marriage using a case made for an ETA/Miyota/DG because the Rlx movements are a little bit larger in diameter than ETA/Miyota/DG movements. Sometimes aftmkt cases are made for ETA/Miyota/DG movements only and a Rlx movement will not fit into the case. Usually not though. Only one each of these so I'll need to keep them for patterns: March 2011 DW project with genuine dial and Rlx 1570/5 movement (has been posted a few times before)... Never got around to detailing the CG. Still have some DW oem spec '1680' cases and Yuki '1680' dials for a few DW/ETA/Yuki projects. They make very good project watches when finished...the cases are precision made and the Yuki dials are pretty good, the problems are wrong case numbers or none at all and slightly 'pot bellied' cases. I will not have time to get to an ETA into Rlx oem spec case swap for a while. From: Building an MBW Sub + 'shortcut' rlx 1560/70 GMT conversions... - The Rolex Area - RWG DW 5513 and 1680 cases... These are all really 1680 spec cases (more or less) so if you have one with 5513 stamped on it, a 1520 and 26mm 5513 dial will mount up in the case but the dial is a bit too small for the dial window and will also be too far from the dial seat. What you end up with is a 26mm dial in a 26mm dial window with the dial mounted about .8mm below the dial seat and nothing holding the dial in place except the dial screws. I did make a very thin spacer out of aluminum to fill in the space on one DW '5513' but it took a long time to make the spacer in a lathe because it was so thin and flimsy. I had to finish it up in an old 8mm WW type 'bezel chuck' made in the 1920s. WW = regular watchmaker lathe. 'Bezel chuck' = a chuck that looks like a steel wheel with concentric grooves cut in it. It will expand or contract a few mm to accommodate small, thin bezel rings etc. DW cases are a low $$ alternative to expensive 'genspec cases' but you will need a genspec bezel kit, crystal, tube, crown etc. Also...as I have mentioned many times before, the DW cases have rounded case sides like a DJ and not flat like a submariner. They could be sanded flat on a disc grinder or by hand but it would take a lot of careful work. One good thing about the rounded case sides is they make the watch look like an old 'high mileage' example with a storied history after they get sufficiently scuffed up. I have seen a few genuine 1680/5512/13 with the case sides rounded from years of wear and numerous polish jobs so there are genuine examples with rounded case sides in circulation.

-

See though Rolex dials "for service adjustments"

automatico replied to Ronin's topic in The Rolex Area

Anyone familiar with this and how to tweak alignments? The 15xx date movements were adjustable by an eccentric screw at the tip of the date jumper, the 3035 has an adjustable tip on the date jumper, and the 3135 date jumper is also adjustable. Some aftmkt dials and/or date wheels might not be made exactly on oem specs and could be past the adjustment limits...have not seen one yet though. -

Did you use a lathe or something more DIY ad hoc like a drill and a file? I used a Sherline lathe similar to this one... SHERLINE 4100 3.5" X 8" LATHE (METRIC) (For INCH SEE PN 4000) | eBay Same lathe with some accessories... Sherline 8 inch Lathe w/Adjustable Handwheels Package C 4500C 784300631125 | eBay There is also a $$ CNC model... Sherline 8 Inch CNC Lathe System Package A 8400A 784300631194 | eBay You do not need many accessories, just a 3 jaw chuck, 4 jaw chuck, and some carbide cutters to get started. I also have a Sherline 'WR Smith' WW collet adapter for small 8mm 'WW' collets... Sherline Products P/N 2110 WR Smith Watchmaker’s T-Rest NIOB | eBay A 3 jaw chuck is good for cutting something from start to finish without removing it from the lathe. The 4 jaw chuck is good for anything that has to be R&R during the cutting process because you can get the part centered precisely when remounted. The Sherline lathe is not reversible but my old C&E Marshall WW lathe is reversible but it is probably 70+ years old and does have very much power (they never did). The Sherline lathe has an 'X-Y' tool feed, but the old Marshall WW lathe only uses hand held gravers and 8mm collets...8mm = the OD of the neck of the collets, the ID is stamped on them. You used to be able to find old WW lathes at garage/yard sales and flea markets...before the internet made them popular. I paid $50 for mine but look how much they are on eBay now... 8mm watchmaker lathes for sale | eBay Also have a Sherline milling machine and it is basically a precision vertical screw feed drill press with the same motor etc. as a Sherline lathe. I use it for small milling jobs like cutting stem slots in movement adapters or cutting a relief on the back side of a dial for platform type dial feet etc. It can also be used to mill a relief or taper on a case where the case tube screws into a case. Using the milling machine compared to a drill press takes some practice. When drilling out lug holes for example, you can 'feel' the resistance with a drill press to tell how fast it is cutting, but with a screw feed milling machine, you can easily 'crowd the bit' and overheat or break the drill bit. Sherline 5000 Vertical Milling Machine 731882165906 | eBay

-

I wonder if 3d printers would work for this. A precision printed hard plastic spacer probably would. Here is a brass spacer I cut for a project. I usually mill the stem notch but since this was a quickie project, I ground it with Cratex. Rolex Wristies thread - Page 139 - The Rolex Area - RWG

-

The 1030 is 28.5mm in diameter, and ETA 28xx or Miyota is 25.6mm. Depending on the ID of the case where the movement is mounted, you will need an adapter that will fit inside the case with very little room to move and over an ETA or Miyota movement. I make mine on a lathe out of a brass washer and I have not seen any for sale since 'Stilty' left RWG and Yuki stopped making a clone of the 'Stilty Spacer'. Stilty Spacers... I ended up with all the Stilty Spacers he had left when he quit the hobby but can't find them, so I've been making them one at a time on a lathe. Stilty's spacers were CNC precision machined but they may or may not fit each application when putting an ETA 28xx or Miyota 82xx in a genuine spec case. Besides that, I usually make the spacers slightly taller than the movement when mounting an ETA in a Rolex spec case so the dial can be mounted to the spacer with epoxy or clear Gorilla glue instead of the flimsy ETA metal spacer when the dial feet had to be removed. Many scoff at this but it has worked for me and the only thing that can get out of whack is if the spacer/dial slips on the movement before the case clamps are mounted to hold it all in place...easy to avoid though. I am pretty busy this summer, but I'll see if I can find the Stilty Spacers. ETA Caliber 2824-2 Watch Movement | Caliber Corner ETA Caliber 2836-2 Watch Movement | Caliber Corner Miyota Caliber 82S0 Watch Movement | Caliber Corner

-

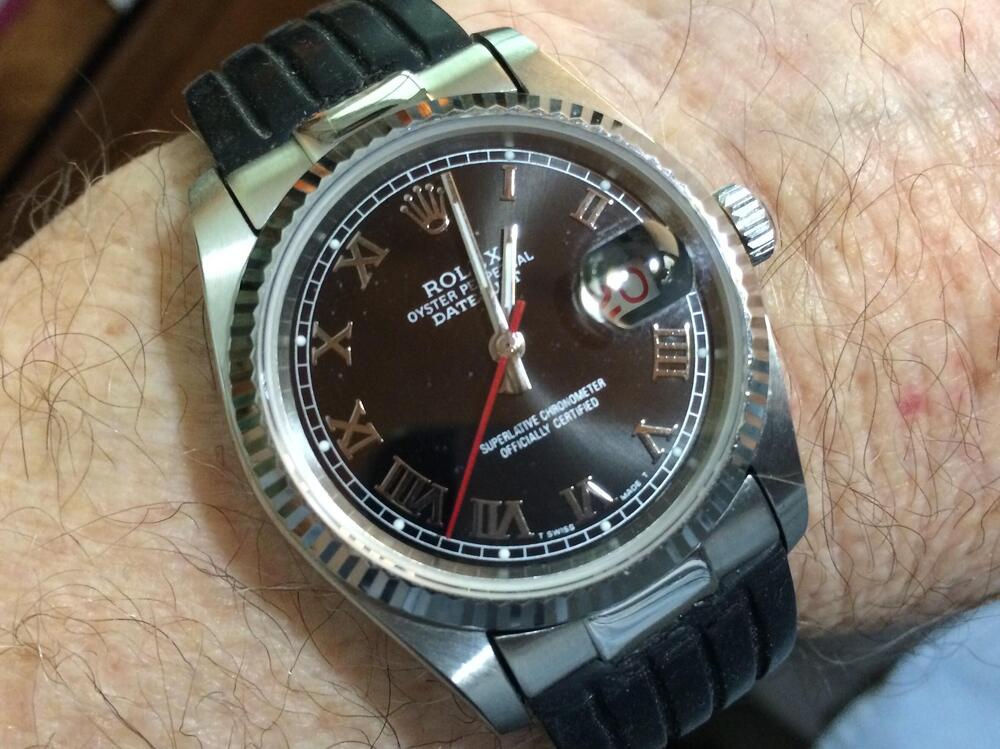

DJ 162xx project watch is 8 or 10 years old with Seagull TY2806, ST oem spec bezel/sapphire crystal & gasket/case tube, riyi hoods, brass mvt spacer w/screws and clamps. WR tested to about 30M. Clasp from parted out '21J Daytona' from 2010 or so. Long, low tension spring bars can be easily adjusted with a toothpick. Silicone 'Aero Classic' airplane tire style strap from eBay. Aero Classic 27 Sc - 10 Ply Rib Tread Tire | Aircraft Spruce High Quality Waterproof Diver Rubber Silicone Watch Strap Band 18 20 22 24mm | eBay Seagull Caliber TY2806 Watch Movement | Caliber Corner

-

Not a wristie, but an Odd Ball 'pockie'. Twelve size 1920s Waltham 'Secometer'17 jewel pocket watch... Have a Hamilton model 912 similar to the Waltham somewhere, could not find it. Speaking of odd balls, a SONY wind-up cigarette lighter... Wind it up with the round button and music plays when you flick the lighter. Probably from the 1950s/1960s. A similar model: SONY-LITE Musical Lighter plays Annie Laurie | #3828352892 (worthpoint.com) Pic of a Hamilton 912: Hamilton 17 Jewel 912 Pocket Watch with 14k White Gold Filled Case Inscribed 1931 | The Fedora Lounge

-

Very low mileage stainless steel Wyler manual wind with slow set date from the 1970s in original condition. 'Front loader' case with the acrylic crystal clamped on the case by the bezel same as vintage Rolex. The case back appears to be removable. It might be...but not without doing a lot of damage. Wyler cal WH234/ETA 2752 with Wyler 'Incaflex' shock system.

-

"How are these?" They look good and I put them on my 'get it' list.

-

"Hey, have you checked yuki for the 1655 handset ?" Yes, they look pretty good, but this kills it: "Flat rate shipping cost : USD 48.00 to worldwide." Besides that, hands used to be included with their dials at about the same prices as today with free delivery.

-

"I blame the recent crop of 'clone' movements & reps." Me too. I would like to know approximately how many 'high end' replicas have been sold in the past 5 years. Many of them probably purchased by people who did not consider buying a replica until the supply of genuine watches dried up, causing long waiting lists and high prices. "I can understand this with high end pieces, but I don't think every DJ will be a highly desired collectable." I am afraid you are right. Afraid because just about all I have left are a few AK and 1600 type DJ after selling anything that is worth high $$ today way too early. I am not alone in this because I hear the same sad song fairly often now. Otoh... I remember back when you could buy or trade into watches for $20 to $30 that are selling for $200 to $300 today. We called them 'casket watches' back then because you were usually stuck with them and all you could do is put in a note in your will for someone throw them in your casket. It was not funny back then, but it's funny now. Why? Because I bought a lot of casket watches. Can replicas be considered casket watches? It probably depends on where you are headed.

-

"I just found a brand new 1570 balance with a broken hair spring in my old box of goodies! any thoughts on it working in a 1530 which is missing the balance?" The 1570 has a different beat rate (19800) vs a 1530 (18000) so I doubt it will work. "Will my 1520 auto assembly fit on a 1530? " Yes.