When you buy through links on our site, we may earn an affiliate commission.

automatico

VIP Member-

Posts

3,180 -

Joined

-

Last visited

-

Days Won

152

automatico last won the day on May 15

automatico had the most liked content!

About automatico

Previous Fields

-

Country

United States

Profile Information

-

Gender

Male

Recent Profile Visitors

14,418 profile views

automatico's Achievements

-

Good to see you back again! Many of the hardcores are still here but things have slooowed down a lot since you left. Things sorta stand still sometimes. I'm still here but don't work on watches much anymore because...well, the fun has gone out of it. High Price$ and No Parts have ruined it for me. Besides that, I have property to take care of (always have) and age is catching up with me, so I've slowed down too. I still try to wear mechanical watches now and then but cleaning out fence rows, mowing, hauling wood, working on houses etc. is not good for them so they are put away most of the time. I carry a plastic quartz watch in my pocket to tell time when working...don't want to work past quittin' time. Ha!

-

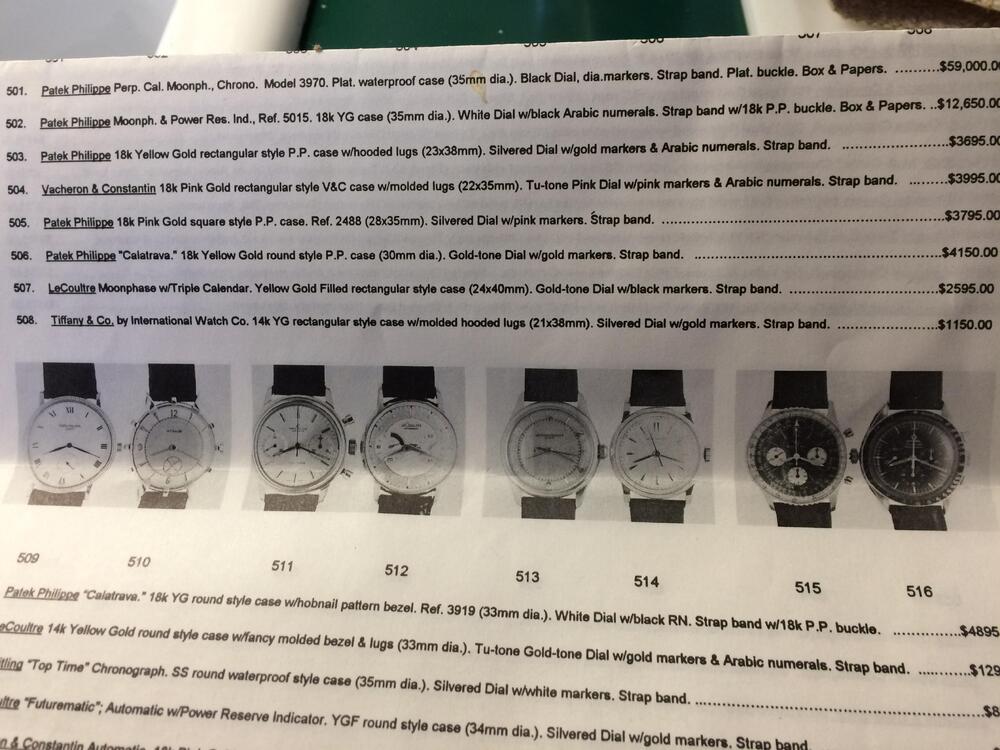

Old mail-out used watches for sale price list...

automatico replied to automatico's topic in General Discussion

"Was it from some jeweler in Texas? I bought a couple of watches from them in the early 90's." Yep, Dallas. I bought a few too, pretty good deals back then. -

-

I am glad not to be the only one to have noticed this. Looks like Rolex info is being dumbed down like everything else. I have also noticed quite a bit of 'disinformation' (political term Ha!) on many forums lately. One exception is 'Xeramic' on VRF. That guy is sharp. Something else...it seems like there are more 'Frankensteins' claiming to be 'genuine' and 'all original' now than in the past. If I can spot one, it's just not too hot.

-

Blasts from the Past... L to R...14K Hamilton 'Wesley' from the 1940s, 9K Buren Grand Prix from the 1930s, 14K Pierce from the 1920s/30s, 14K Lord Elgin with 'step side' case from the 1950s. The Hamilton looks like new. The Buren has a 15 jewel high grade movement with 'three finger bridges' and uses a 'sew on' or one piece strap, the strap bars are soldered in the lugs. The Pierce has 15 jewels iirc and is in fine condition. The Lord Elgin is in fine condition except for the 'age spot' on the dial, it has not been wet as far as I can tell. The dates are a guess and info on the Hamilton and Lord Elgin can be found but I am too lazy to chase it down. Many Hamiltons have the model name engraved inside the case back. After the current 'Gold Rush' pans out, there may not be many of these old classics left.

-

I might have posted this before, can't remember. Anyway, this is from the early 1990s iirc, can't remember exactly when either. I have more, maybe I'll post a couple with dates. NOS Slinky w/box, American Racing magnesium/aluminum wheel catalog from the 1970s, Baylor 17 jewel RR style watch from 1970s, radiator tube from a WW II Lockheed P38 Lightning fighter plane, candy cigarettes from the 1970s (leaning over, far right), Bob Marley coffee cup from Jamaica etc. P-38 Lightning. Lockheed P-38 Lightning - The American Heritage Museum

-

-

Franken genuine omega or maybe just mix and matching.?

automatico replied to Timelord's topic in General Discussion

Horo is right. Vintage Omega Rules: Rule 1: Nothing Fits. The part might look right, but it usually won't fit. Rule 2: Many 'front loader' dress Seamasters have rusty movements. I call them 'Rustmasters'. Q...How do they get rusty? A...The two piece crown wobbles, the gasket wears out, and water gets inside. Rule 3: Stay away from them unless they are complete, running, and oem spec...or cheap as dirt. Something else...on many models the crystal helps hold the bezel on. The crystals are 'mushroomed' at the top. If that is not bad enough, most no longer have oem spec crystals (no 'shroom top) so the bezel falls off. -

"I want to share my latest project. Not ready yet but gives a clue how it comes out." Looks like it's off to a very good start!

-

Rolex MilSub ref.5517 Project: BUILD

automatico replied to ChiefGoatHerder's topic in The Rolex Area

"5513 Comex with gen dial" -

I'm planning the same build, only I can't decide between the Yuki or Mochacha dial. Yuki dials are fine, the prices are Ok, and I would like to have one for my SD except... "Flat rate shipping cost: USD 48.00 to worldwide." It would be Ok if ordering 4 or 5 dials...unless they try to charge $48 for each dial. This Higher and Higher priced 'hobby' is beginning to $Burn Me Out$.

-

Rolex MilSub ref.5517 Project: BUILD

automatico replied to ChiefGoatHerder's topic in The Rolex Area

This is not about the milsub, but a '5513' type case can also be used to put a 'pre COMEX 5514' submariner together if anyone does not want to hunt down the $$ milsub case, dial/hands and bez insert. The fixed spring bars can be made using stainless steel rod stock similar to eBay item 284520669214 or a bracelet can be used. A short piece of SS rod can be polished on one end and pressed into a hole drilled in the case for the He valve. -

Stuck this together in late 1990s, Croton/Nivada base with quick set Swiss ETA. Stainless 36mm screw back case with GS Ever-Tite acrylic tension ring crystal. Dial refinished by an outfit in Atlanta, GA (no longer in business). Genuine Ingenieur... Fine watches...except for no parts. Vintage IWC automatics had a winding setup using the same principle as the Seiko Magic Lever. Images from Connoisseur of Time.

-

Lets revive this section.. Show Your Omega

automatico replied to docdoowop's topic in The Omega Area

Here is most of what is left of my vintage Omega 'collection'. May it RIP. Iirc, I do still have two or three running Omegas somewhere, one being an old bumper wind Seamaster. Used to wear a vintage Omega now and then before parts went n/a. It has been said that Omega (back when it was Omega, not Swatch-O-mega) went down the street with wheelbarrows, buying parts from anyone who had them. Then they all met in a back alley and stuck watches together using the parts. Of course it was just a joke, but after working on them... Even if two Omegas look exactly alike...they are probably not alike. The 5xx movements were their Heroes. The 1000 series was their Downfall. Imho. Quartz watches were rapidly killing off mechanical watches back then anyway. Today's Coax is cool but who is going to fix it when it blows up? Not Uncle Bob's Watch Repair down the street, all he does now is swap out dead batts because he can't get parts. Oh, I forgot...Swatch-O-mega Inc. will fix it for only $950 (just a guess). Plus tax and shipping charges. It's no wonder why replicas are such a Big Hit today. Color me cynical. Just a little bit. Ha! Omega's Biggest Mistake: Calibre 1000 (youtube.com) 4-19-24...Pic of the old bumper wind Seamaster mentioned above... Ratty redial but the watch is in good condition, no case corrosion or rust on movement. -

Another Gold Rush deal... Rolex rivet bracelet 7205 with 71 end links for £3,769 for sale from a Private Seller on Chrono24 £3,769 (4762 USD) "Very rare" "Worn with little to no signs of wear"