When you buy through links on our site, we may earn an affiliate commission.

-

Posts

15,787 -

Joined

-

Last visited

-

Days Won

194

Everything posted by freddy333

-

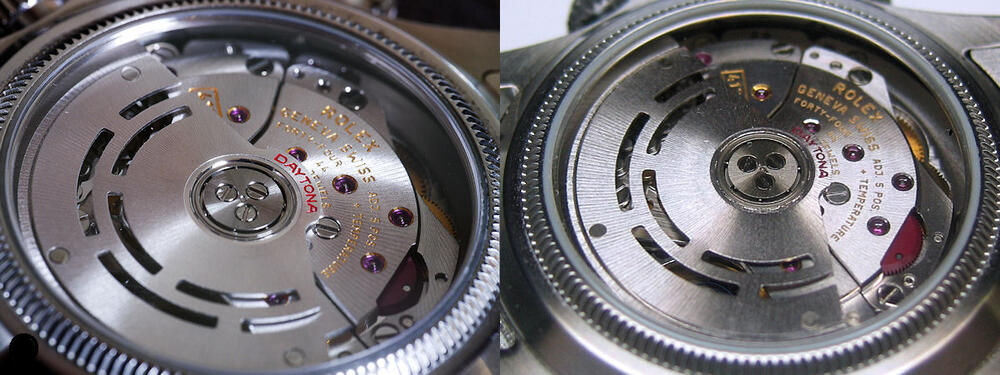

The 2023 Platinum Daytona (ref 126500) becomes the 1st sport model offered with a display caseback. It also has an updated 4131 movement. The 4131 is supposed to have a few less parts, but I do not know which parts were removed or why. What I do know is that the new movement is now decorated (not to my liking) & fitted with a skeletonized, yellow gold rotor & 'improved' ball-bearing system. I was not aware of any general problems with the 4130's rotor bearing, so the 'improvement' may be in manufacturing process & not the movement's performance. But, since they greatly increased the number of balls in the bearing (it looks like they went from 7 balls in the 4130 to 30 or 40 in the 4131), I am not sure about this? Rolex says 'the self-winding mechanism is also more durable thanks to the optimized ball bearing in the Perpetual rotor'. Rolex is now surrounding the ceracrom bezels with metal, which I imagine is designed to address the increasingly common problem of shattered bezels due to side impacts.

-

Condolences on your dad's passing. He had great taste in watches (I have the same model).

-

The movement is 1/3 of the chase. The movement & dial represent the other 2/3. But, however you look at it, no 1 part is useable without the other 2.

-

Good points. I still have a 23-300 with dial/handset that has been sitting on my bench for years awaiting a Patek case -- at this point, almost any Patek case that fits -- but none are to be found anymore. As automatico said, most have been sold off for their melt value &, even with inside contacts, Patek, like Rolex, will no longer sell or permit parts transfers out of the mother ship & its satellites.

-

I feel your pain (but the suffering is worse because I lack such an extensive collection of new/NOS Rolex crowns). If I gave an AD $10k for every time I have hidden an important Rolex part from myself, I would have enough to merit the privilege of buying a 116500 at retail.

-

-

Most likely. Click here

-

I have no recent experience with Phong's watches, but, back when I was more active, I had some (repair) experience with a few of his Rolex frankens, which varied from satisfactory to nightmarish (worn parts cemented in place, etc.). As I recall, Ziggy posted a number of threads detailing some of what he found inside these watches. At that price level, I would either buy a 2 or 3 hand gen or educate yourself on the parts required to build a franken, gathering them yourself & having a local professional watchmaker assemble everything for you. Another option would be to consider 1 of the recent high-end Patek reps that contain gen-like movements. As is the general rule with reps, avoid the more complicated models & those with 'gems' & you should not have too many problems. Unfortunately, these high-end Patek reps are somewhat rare (I tried to purchase a Calatrava recently, but the factory ultimately said the watch was not currently available & had no ETA when they would be), so you may need to spend some time & effort to track 1 down.

-

-

As usual, nicely done.

-

Looks good Tribal.

-

Still a beauty & it may be the camera angle, but it looks like the index markers at 3 & 6 may not be straight.

-

Looks beautiful. Based on the way the watch sits (close) to your wrist, it looks like you bought 1 of the 4130 clone Daytonas, which has the proper bezel & caseback profiles. Correct?

-

Sorry to hear the sad news. Unfortunately, crime has become the new normal & the system has become an accessory to those crimes. I know it does not help in this case, but I ship anything of value via registered mail & give the tracking number to the receiver so both of us can track it all the way. Yes, registered mail is very slow because every single person who takes possession of the package must sign for it & note the time/date the package was in their possession & the package is kept in locked containers when not in a mail employee's possession, but I have never lost a package using this shipping method.

-

I am confident that a properly assembled Longines can be adjusted to a fine degree. However, regardless of how 1 adjusts Longines' balance sliding screws, the procedure will be less fine-tunable & repeatable than Rolex's Microstella system, which uses a wrench with discrete adjustment indicators & a balance fitted with 2 pairs of Microstella nuts providing consistently repeatable +/-1 sec/day or +/-.7 sec/day tuning increments. All other things equal, due to the subtle adjustments possible with a free-sprung balance, attaining 0 beat is very easy.

-

In honor of the 1 year anniversary of the war in Ukraine, I am wearing my (often accurate) Russian Commando Frogman watch

-

Imagine an ice skater spinning in a circle. As she folds her arms in close to her body, she spins faster, as she folds them back out away from her body, she spins slower. These centrifugal adjustments in balance wheels work the same way - as you move them inwards, the wheel spins faster, as you move them outwards, the wheel spins slower. I have never worked on a Longines with the type of adjusters indicated in your pic, but I have a good bit of experience with Rolex's Microstella system & it works (very well) as advertised. The Etachron instructional video posted previously is a good guide. Did you try it?

-

Rolex's Microstella system is not designed to provide a performance improvement, it just permits you to make very fine & consistently repeatable timing adjustments via a pair of nuts that are difficult, if not nearly impossible, via a traditional regulator setup. Yes, the system is finicky & requires a special tool (Microstella wrench). However, if you have the tool & know-how, the system allows for a much more accurate degree of timing than any other system I am aware of. Before I got used to it, I did not get it either. But once you get it, you get it. Ebay 265389584078 or 254991498290 Startime & other watch parts houses sell them as well.

-

Left is gen.

-

-

Although the comparison macro pic post above had many views, I am not surprised only 1 viewer took up the challenge. The differences are more interpretive than real. porschespeedster -- You are correct on all counts except for 1 -- the dial on the right is actually the fake. But you are in good company because I just asked a friend who is a master watchmaker with a Rolex parts account to check it, inside & out, & he assumed it was real, too. He nearly fell off his chair when I revealed the truth. Took a 2nd look & still could not believe what he was seeing. The only tell is the watch's lack of heft, which is revealed when the real, SOLID gold Daytona & the fake are each weighed on an accurate scale. (The steel Big Kahuna does weigh the same as the gen. ) The point of this little exercise is that for the 1st time in my decades of collecting -- & although I would be the 1st to admit that I am NOT the world's most knowledgeable Rolex authority, I AM pretty savvy -- if I had not known the background of these 2 watches, I would NOT be able to tell the gen from the fake. Even upon close inspection with a loupe. Weight differences aside, even if I could hold both gen & modified fake watches in my hands and inspect them with a quality loupe, inside & out, I could NOT tell the difference without disassembling the movement (which WOULD reveal the fake movement's non-Rolex-like internal parts fit & finish). Yes, there are slight granular differences in the exposed surface metal of the rotor & bridges that CAN be seen, but, if all else looked copasetic, these would not even register in my brain or I would dismiss them as within the normal manufacturing tolerances I have seen in all Rolexes. More to the point, if I was able to figure out that these new clones are nearly indistinguishable from their gen counterparts (& literally indistinguishable with just a few gen parts swaps), I am sure Rolex has too & probably long before I did. So it is only a matter of time until word gets out to the wider gen collecting community & then into the gen watch buying marketplace. Once this starts getting reported by social media influencers, Rolex will be forced into a corner because gen buyers who love to proclaim 'I would never wear a fake Rolex!' will quickly change their tune to 'I would be crazy to spend $50k on a Swiss-made Daytona when I could buy the same thing from the Chinese for less than a grand -- & have it on my wrist in a matter of days rather than years!' &, as you can see HERE & HERE, Rolex is only digging themselves deeper into the hole the Chinese may bury them in. As auto indicated recently, I think it is likely that we will be seeing THE MOTHER OF ALL ROLEX REPLICA CRACKDOWNS sometime soon. Things will have to get crazy, so get yours while you can. p.s. Eventually, the FASHION winds of watch collecting are going to change direction & most of the short-attention-span under-50s who, just 6 short years ago, were proudly proclaiming 'I do not need a watch' or 'Rolexes are for old men' will dump their recently amassed (& often massive) Rolex collections for the next big FASHION thing (probably some AI-based, beam-me-up-Scotty dual-reality gadget ). When that happens, the entire market may experience the largest collapse since the Quartz Crisis of the 1970s.