RWG Technical

Platinum Member-

Posts

3,908 -

Joined

-

Last visited

-

Days Won

4

Everything posted by RWG Technical

-

Barn find Hamilton stamped USN. Comments?

RWG Technical replied to Jkay's topic in General Discussion

Great find. Please keep in mind that this is probably "RADIUM" so be careful, very careful...you don't want to end up like the radium girls... -

Can't say for sure how they are oriented from the Omega factory... but in the case of your Speedy...I do know that the crystal is now oriented correctly and right side up. Chrono was a challenge for sure, but I am always up for a challenge. Hope you like the results...

-

Very nice, well done.

-

It is centered, what you don't see very often is it oriented correctly, many watchmakers don't realize it's there and install it crooked or upside down. I always make sure to orient it properly, like the coronet engraved on rolex crystals, it should be lined up and oriented properly, it's all in the details... I think most Speedmasters use plastic crystals, if your crystal is plastic and it's not got the logo on the middle of the inside, it's not a genuine crystal.

-

I have never seen it on a rep crystal. The Omega symbol is on ALL genuine Omega crystals (at least the plastic ones), if it's not there, the crystal is not genuine.

-

If you remove the case back and re-install it without the gasket, you can check and test for rotor freedom. An easy trick is to put a drop of oil on the rotor, then check if the oil has transferred to the inside of the caseback. There is just enough room for the rotor, I doubt you can remove any significant amount of material...unless of course you go the Franken route.

-

Moded Noob 6497-2 very close to Gen. post your thoughts

RWG Technical replied to marlin22's topic in The Panerai Area

. -

Pay the extra for the ETA. If it's in need of servicing you have the option of getting parts, asian no parts are available. Best value for the money, ETA hands down...

-

Cracked Jewels - what is going on? A6497-1 defect

RWG Technical replied to RWG Technical's topic in General Discussion

Don't know if there is a connection. Trying to estalblish some sort of link is beyond what little spare time I have at the moment... I think it's random, like the bent and broken seconds posts. -

Cracked Jewels - what is going on? A6497-1 defect

RWG Technical replied to RWG Technical's topic in General Discussion

It's very odd and unusual. Two in the last week is a lot, since zero were found before this...hopefully not a trend. Both watches were completely different models, one a franken, one new, so no link that I can make at this time, except maybe the movements were the same source. Even if members did open the caseback and found a cracked jewel, how would they fix it? You need a good loup to see the crack and when the movement is assembled, the jewel and pivot are oiled, it's not easy to spot a crack, a piece of lint can also look like a crack. Hopefully others can share any further info. -

Cracked Jewels - what is going on? A6497-1 defect

RWG Technical posted a topic in General Discussion

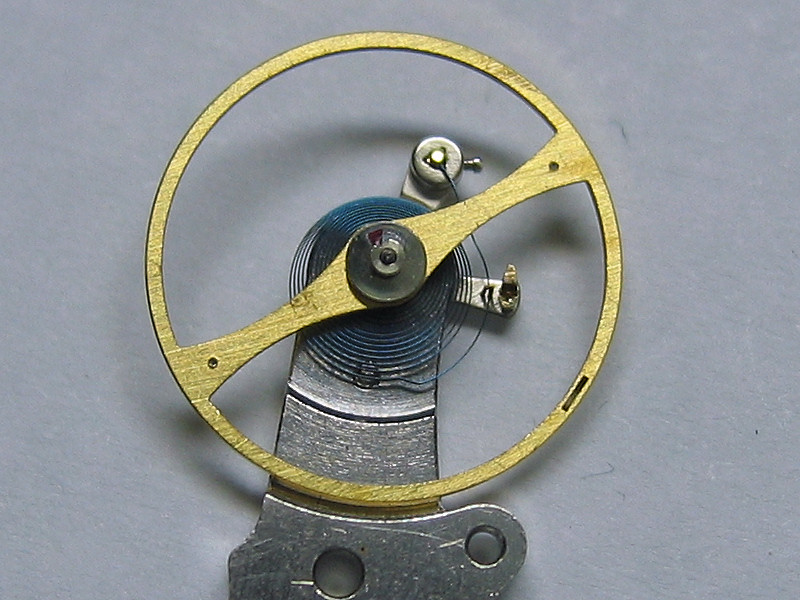

Not sure what is going on, but this is the second time in less than a week that I have found cracked jewels on an A6497-1. This is the only time I have come accross this problem, it's very rare except in old pocket watches that have been tinkered with by the unskilled. Both times the jewels were the top escape jewels (the one you see through the caseback), this one is only cracked through one side, the other was cracked completely accross in 2 pieces. Replacement is not straight forward, my Seitz Jewelling kit doesn't have the required 10/170 replacement jewel (10 is the size of the hole in 1/100mm and 170 is the diameter in 1/100mm). My sizes are 160 and then 180. So in order to install the 180 diameter jewel, the existing hole has to be broached to 0.179mm, the 0.001mm smaller diameter for the hole is what is needed to press fit the jewel and secure it to the escape c0ck. I am suspecting that something is happening during assembly, given that the pivot on the escape wheel is only 0.09mm in diameter, it's unlikely that it's causing the breakage, the pivot would fail before the jewel did. Most likely the installation of the jewel into the c0ck is where it's failing. Here's a picture of what I found today. Keep in mind that the jewel is sapphire, next harder substance is diamond. So if you have a cracked jewel, with a sharp edge made of sapphire, with a steel pivot turning in it and rubbing up against the sharp edge...guess what's going to happen and eventually fail. Hint...it won't be the jewel. All the more reason to never take for granted that all is ok, even on a new movement. Critical to inspect each and every part and component, you never know what you'll find...anyone else come accross this defect? -

So what the heck is the "Incabloc Y mod" anyway...

RWG Technical replied to RWG Technical's topic in General Discussion

Incabloc, like KiF produce dozens of variations on their shock settings. I think this is simply down to the choice of Incabloc setting purchased and installed. In other words, the genuine Incabloc comes already "Y" modified, it's most likely a higher end model than the rep ones... -

So what the heck is the "Incabloc Y mod" anyway...

RWG Technical replied to RWG Technical's topic in General Discussion

Thanks everyone for the positive feedback. It can be done without servicing, or in conjunction with servicing. During servicing it's about 30 minutes of labour, stand alone it's close to an hour of labour...priced accordingly. Nil change in functionality, it's purely a visual effect to duplicate the gen. For the discerning detail oriented owner... -

So what the heck is the "Incabloc Y mod" anyway...

RWG Technical replied to RWG Technical's topic in General Discussion

Thanks guys. I didn't coin the term, and I didn't come up with the modification. I was asked if I could modify a setting to look like the gen, and it so happened that I had a genuine Panerai in house to use as a model. It's a lot of work as you can imagine, removal of the balance and pressing out and in of the jewel setting assembly is quite involved. Results are nice. But like all mods, it's up to the individual if it's something they want done. -

The Incabloc is the shock setting that is installed on the balance c0ck and on the mainplate of the movement. Each Incabloc hold a jewel assembly supported by a spring to prevent damage to the balance wheel pivots due to shock, bumps, etc. On the asian rep movements, the Incabloc looks like this. Both openings for the spring are straight sides and shaped somewhat like an "I". REPLICA movement INCABLOC The Genuine Panerai movement on the other hand looks like this, it's got one end that is straight sided, but the other end is curved... GENUINE movement INCABLOC A closer look at the balance c0ck and you will see the detail of the modified jewel setting. GENUINE CLOSE UP I have circled the section that is different on the genuine Panerai movement, you see how the straight sides have been cut away and curved. I don't know who came up with the term "Y", but if you note the shape of the attachment for the spring assembly, it does somewhat look like a "Y". MODIFICATION Here is a standard replica movement, AFTER I modified the Incabloc setting to look like the genuine setting. The work involved requires that the spring and jewel be removed, then the balance wheel is removed, then the setting is pressed out from the balance c0ck, the "Y" is created by hand, it's cleaned up, then re-assembled, balance adjusted, etc. So there you have it, the "Y Incabloc" modification is nothing more than reshaping the Incabloc setting to match the type of setting used on the genuine Panerai's...now you know. Thanks for reading.

-

If you have to tell the watch guy how to do his job, I suggest you find someone qualified. It's like having to explain to your car mechanic how to fix your car...find another garage...and quick...

-

Swiss ETA 2824-2 issues - Fixing it

RWG Technical replied to whiteshields1830's topic in General Discussion

My comment was more towards the watchmaker and his knowledge and ability. Based on your being able to get the watch going by winding it tells me that as I suspected, the wheel is fine, you have another problem with the watch, most likely a rubbing hand... Sorry I can't offer anything else, good luck in sorting it out. Stuff happens, unfortunately... -

Swiss ETA 2824-2 issues - Fixing it

RWG Technical replied to whiteshields1830's topic in General Discussion

I can't remember when, or if ever, I have seen a movement with a "gear issue". If the watchmaker used the term "gear", then you have problem. The odds of a "gear" (the correct term is "Wheel" not gear...) being faulty is next to nil. If indeed the wheel was defective, it would not be able to turn past the damaged teeth and would stay stuck at 25.... Most likely causes could be as simple as the seconds hand touching the bottom of the crystal. If you can, try and find a real watchmaker who at least knows the correct terminology for watch parts. I believe you are being lead down the path... Never, ever, send anything back to China. Have it sorted out locally or with someone you can trust. -

Acetone is not selective, it will remove everything...don't use it near the dial unless you want a brass plate with no markings. The only way is with a 4X loupe and a small scraper, you scrape each and every letter off carefully trying to only remove the white lettering paint and not the base paint. I have re lettered dials from "L Swiss L" to "T Swiss T", it takes a lot of time and patience. You would probably have to touch up the dial after removal as well as clear matter coate it to blend it all in after your done...

-

It looks great in your hands. Glad to be of service.

-

FAQ: To service or not to service? My thoughts.

RWG Technical replied to Rolexman's topic in General Discussion

Very good info. My recommendations are always, are you planning on keeping the watch. If yes, then consider it for servicing. If no, then wear the watch and enjoy, when it fails, get another. Experience has proven that a properly serviced movement, will perform as it should, and if serviced every 5 years or so, will not wear out. Did you ever wonder why watch owners only contact the watchmaker after the watch has developed problems or stopped running altogether? There aren't very many owners who think preventative maintenance and send them in before they have issues... -

Given the rarity of the parts, you may pass out before finding one...

-

Interesting...but somewhat disturbing... If you have a hairspring that looks like this, and you have to ask Then maybe, just maybe, you need to take a few more watchmaking lessons... Kalf must be loosing his arrogance, normally he would be all over someone who was this incompetent.

-

Guess the info was of no value to the OP...nil reply or thanks....

-

Focus everyone...focus...way off topic, bears in the woods with glowing eyes, death stars and Klingons, why does this always happen. So you have gotten 3 years of cheap entertainment with your lume, sounds like it was a good investment. I find the wife's comments somewhat hard to believe, it's probably more like %$#$@#@#$ &&^%$%$&*( *&&^^ &^%$$ ...your watch is too bright...&(&*$%&$!&%%#&*&***#* or something along these lines...