-

Posts

551 -

Joined

-

Last visited

-

Days Won

4

Everything posted by RickFlorida

-

If you have a 5512/5513/1680 with a loose bezel. . .

RickFlorida replied to cjjoyce1's topic in The Rolex Area

He go's by "Nostalgia2000 on ebay but say's "Clarks watch parts". So I think that's how you buy Clark's parts? -

Ah man, both of his guides have no pictures anymore. Too bad that posts that are stickied don't get permanently hosted images.

-

Edge's Guide To Some Rolex Modifications

RickFlorida replied to Edge's topic in Watch Repair & Upgrade

Yep... no images really sucks. But I appreciate that this post was made. There should be a way to permanently host images these days. -

Hello everyone. I finally got to the point where I am doing my first modification and will be installing a new plastic crystal for a 5513 type case. I know that for metal we can steam clean parts, etc..... I also know that you can use rodico to pick up dust or oils and that you should use a blower to blow out dust. But my question is.... do you guys also wipe the inside of the plastic crystal before assembly in case there are finger prints, etc on it? For my first test fit, I'm using a crystal that is not sealed in a package but has probably been handled already. When I clean metal or glass, I like using denatured alcohol because it cleans and completely evaporates quickly. But plastic watch crystals would probably be ruined by strong solvents like denatured alcohol. How do you guys clean or wipe the inside of a plastic crystal before assembly? Thank you, Rick

-

Does everyone in the UK get free Lasik surgery? I ask because so many people are saying it's dangerous to wear cheap sunglasses because of UV light but if you wear contact lenses, a lot of them block UV light. So if you wear contacts that block UV light, you can probably get away with wearing cheap sunglasses. Just something not a single person has mentioned so I was wondering you guys with free healthcare get free Lasik surgery? It's about 6K here in the states and you have to pay cash.

-

OK, thanks Sogeha. I will first try this weekend to find an M3-90 degree countersink but If I can't find one, yes please I may have to take up your help.

-

First, my apology for the repeating of my question. There was a glitch today where I kept trying to post one reply and it never went through. I see now that it did and they all merged? Sorry about that. Secondly, thank you so much for explaining the tools you used. This makes sense now. Very helpful to know what you used, especially since here in the States it's not always easy to find metric items so I just needed to make sure I had exact terminology. Cheers.

-

I really like listening to heavy metal on Spotify, but I don' know much about who the bands are. So any recommendations for me of bands if I like to listen to heavy metal I hear on Spotify?

-

Could you please elaborate on how you countersunk the crown opening? I don't understand how you used a small 1.3 drill bit and a 6.3mm bore. Are they used at the same time or separately? Great job by the way! Could you please elaborate on how you countersunk the crown opening? I don't understand how you used a small 1.3 drill bit and a 6.3mm bore. Are they used at the same time or separately? Great job by the way! Could you please elaborate on how you countersunk the crown opening? I don't understand how you used a small 1.3 drill bit and a 6.3mm bore. Are they used at the same time or separately? Great job by the way!

-

Could you please elaborate on how you countersunk the crown hole? You say a 1.3mm drill and a 5.3mm counterbore. But what exactly is the little 1.3mm bit doing for the countersinking? Great build by the way! Could you please elaborate on how you countersunk the crown opening? I don't understand how you used a small 1.3 drill bit and a 6.3mm bore. Are they used at the same time or separately? Great job by the way!

-

Great post. Would like to know how American guys get adderall as I'm interested.

-

Love this forum! I checked the technical/references section but I didn't see any links to exploded diagrams or measurements for parts of Submariner cases like the 5513. Does anyone know of any diagrams or exact measurements of all the case and bezel parts? My questions about the rehaut were answered but there must be a diagram or list of "tolerances" for all the parts? Thank you, Rick

-

Thank you so much, guys! I really appreciate it. I want to take my time building this 7928 using a new 5513 Cartel case. I have fabrication skills to a degree so I could even weld or braze in thin sleeves of metal if I had to in order to bring the case closer to spec. But, if I can simply find the right fitting crystal, that will be easier. So if I want a low dome crystal, there are various brands and slightly different sizes, that is good to know. Who makes the most gen. like fitting bezel, retaining ring, and tension ring combo? I heard WSO is not bad, but then I read Clarks is OK except the tension ring is too thin or too thick. What might make it easier than explaining is can someone please share a link or file that has diagrams with exact thickness of all the parts on a 5513? (Like the dimensions of the proper tension ring, and the dimensions of the case, etc.) With 30 years of the 5513, there has to be an "exploded" diagram showing tolerances/sizes. Thank you! Rick

-

Font and dimensions of 9411/94010 caseback?

RickFlorida replied to RickFlorida's topic in The Rolex Area

No worries Jorrie. Take your time. I expect you may need more explaining anyways. I don't even have all the materials for photo-etching yet anyways. If you need 2 weeks or even longer before starting, no worries. -

Hello everyone. I am going to build a watch using a new Cartel 5513 case. What is the exact size of the rehaut supposed to be if that is what creates the water tight seal against a low dome crystal which I plain on using? I'm going to try to make the watch as water resistant as possible. I will use a new Athaya crown so I will properly seal the threads and also will use good siliconed gaskets . So my only concern for planning the build is getting a tight-ass seal on the crystal. So may I ask what should the dimensions of the rehaut and the crystal should be for a tight original style fit? That way..... let's say the rehaut on a Cartel 5513 is a bit too small.... then maybe I can find a slightly thicker crystal? I don't want to use glue.. Since glue will dissolve in saltwater often and is messy. thanks for any advice.

-

Font and dimensions of 9411/94010 caseback?

RickFlorida replied to RickFlorida's topic in The Rolex Area

I forgot to mention JMB nailed the font as well, this goes without speaking. If I were to have someone engrave it, it would be JMB. In fact, even if I finish this experiment up, I may end up having him engrave the whole case for me. I mostly want to see if this works. Just saw this note about scanning. Yes, I'll send you a scan of the case too. -

Font and dimensions of 9411/94010 caseback?

RickFlorida replied to RickFlorida's topic in The Rolex Area

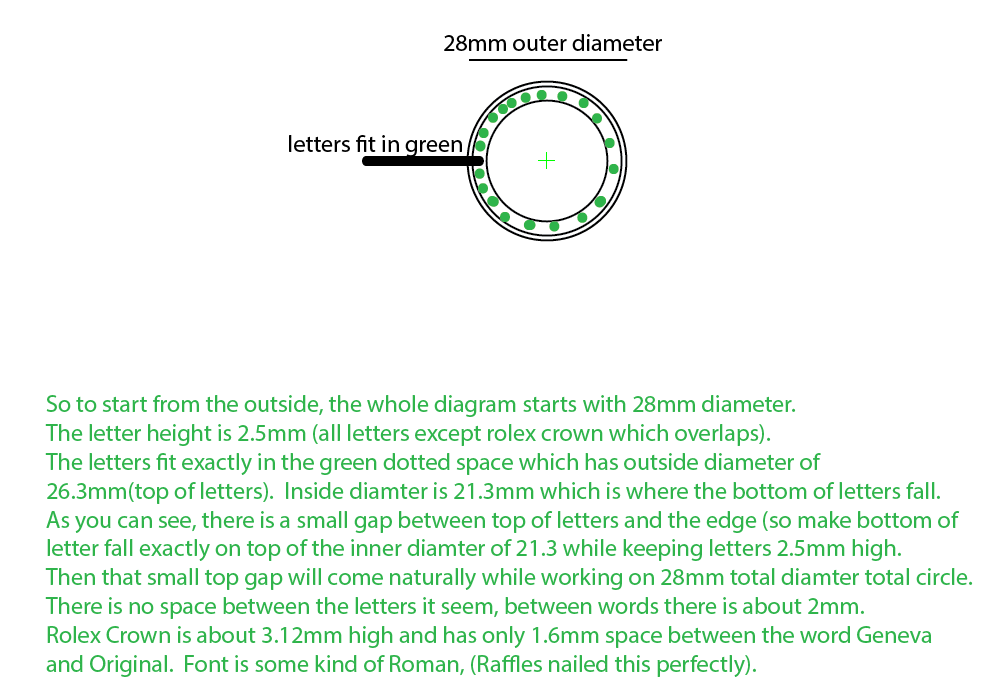

We are finally at the next stage of trying to etch a decent engraving of a Tudor caseback. One thing I have noticed.... is that Raffles NAILED the font perfectly. I'm really impressed. If only the Raffles Tudor caseback was not missing a gasket groove, then hands down his caseback is a great candidate to use if you ever find one. But anyways, Raffles and I'm sure Yuki probably found the Roman style font that is used on originals. I have not idea what exactly kind of Roman font it is but I think it's Roman because of the unique "T" in "Oyster". Is anyone friends with Raffles or others who have created this font engraving before? Anyways, we have the diagram done and now am just trying to create a template. My only concern now is that I realized I can't use my method of choice in using an industrial laminator to adhere the template to the caseback before etching. Because of the unflat shape, I will have to try photo etching. But the results should be even better. -

What part of Florida does Vac work in?

RickFlorida replied to RickFlorida's topic in Vac's Modification Shop

Vac, I want to send you a message but says.. "Vaccum can't receive messages". I have a job if you are interested perhaps. -

Waterproofing the newer Cartel 5513 Cases?

RickFlorida replied to RickFlorida's topic in General Discussion

Yes Gents.... I found my error. The Cartel Caseback does have a nice groove for placing a gasket. My confusion came because I was looking at the back of my Raffles Tudor Sub caseback. It does not have a groove at all in that caseback. Does this mean later Submariner cases don't have it or is it missing in error on the Raffles caseback? So my initial worry is solved. I will sand the flat part of the case perfectly flat to help with sealing and get a better fitted gasket. The one that came with the case is a little too big in diameter and does not stay in position. How do you guys water proof the crystal/bezel seal? The rest I can figure out (crown tube and caseback) -

Waterproofing the newer Cartel 5513 Cases?

RickFlorida replied to RickFlorida's topic in General Discussion

Thank you. I will check it and see because perhaps you are correct that I didn't check enough if there may be a groove on either the caseback or not. I'll take pictures if I'm still not sure. Thank you, Rick -

Greetings everyone. It's time I get back in the game after a while. While I'm working on creating the tutorial on how to precisely etch casebacks for creating Tudor sub casebacks, I have another goal I want to accomplish. I have one of the new Cartel 5513's and wanted to please ask about the case gasket. I noticed when I removed the caseback I don't think there was a groove for the gasket. It seems like the gasket is just squeezed between the caseback and the case without any particular "seat". Have people who are serious about waterproofing these cases done mods like creating a seat for the gasket or are there replacement casebacks that have a groove? I'm going to strip my Josh 5513 down and use an Athaya crown so I will properly seal the crown tube opening so I am just concerned with the caseback and later the crystal fitting. Thanks for any advice. If fitment or room allows..... I bet the easiest way to create a groove or seat for the gasket is to take a stainless strip/wire and braze/solder that on the inside of the caseback. I have soldering and welding skills to do this but I was wondering if anyone who has already done something like this has any advice about placement or procedures.

-

Cartel Revised case shape Vintage Rolex model on Perfect Clones

RickFlorida replied to denimhead's topic in The Rolex Area

What does "DWO" stand for? -

Font and dimensions of 9411/94010 caseback?

RickFlorida replied to RickFlorida's topic in The Rolex Area

Yes my friend. It's extremely useful. In fact, I may be able to just make the vector template myself now. I may use Sketchup LayOut or Illustrator. I will start as soon as I'm done with a current project. -

Font and dimensions of 9411/94010 caseback?

RickFlorida replied to RickFlorida's topic in The Rolex Area

Just an update. Hologramet has sent me one through the mail from Sweden. So I'm just wanting to get the Tudorcase in the mail so I can finish a template for the etching project. Sorry for the delay but I figured it will be more accurate in the end. (providing that donor caseback is fairly accurate in font and size).